Method for producing hot-forming part with variable strength and lower die base of die

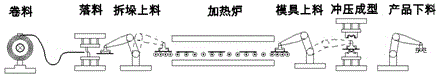

A technology of thermoforming and variable strength, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., and can solve problems such as poor effect, inability to control accurately, and inability to obtain expected material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

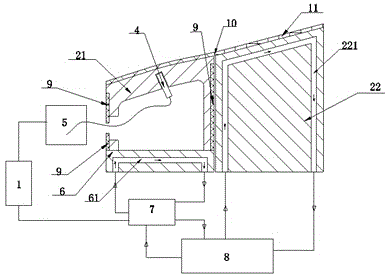

[0024]This embodiment provides a lower die base of a mold for producing variable-strength thermoformed parts, such as image 3 As shown, the molding block of the lower mold base is divided into two parts: the high area molding block 22 and the weak area molding block 21 (it can also be divided into a plurality of high area molding blocks 22 and a plurality of weak area molding blocks 21, in this embodiment only Take a high area forming block 22 and a weak area forming block 21 as an example for illustration), the high area forming block 22 is provided with a cooling water pipe 221, and the cooling water pipe 221 is directly connected with the cooling water generator 8, and the weak area is formed The cooling water pipe 61 of the block 21 is arranged in the temperature control block 6 below the weak area forming block 21, and the cooling water pipe 61 communicates with the cooling water generator 8 through a flow rate controller 7; it is also fixed inside the weak area forming b...

Embodiment approach 2

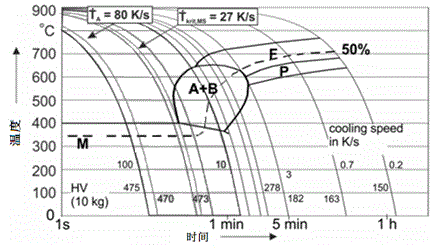

[0035] In this embodiment, the plate material is boron steel with a brand name of 22MnB5 as an example for illustration.

[0036] First, heat the boron steel plate 11 to 900~950°C and keep it warm for at least 5 minutes to make the boron steel plate 11 completely austenitized. The forming block 21 is heated to 400~500°C, then the auxiliary heating device 3 is taken away, and the red-heated boron steel plate 11 is immediately transferred to the forming block of the lower die base in Embodiment 1 for stamping. The transfer process lasts for 8 seconds. And ensure that the area that needs to be processed into high strength in the boron steel plate 11 is placed above the high area forming block 22, and the area that needs to be processed into weak strength is placed above the weak area forming block 21, and stamping starts after being placed; : (1) The cooling water pipe 221 inside the forming block 22 in the high area is filled with the fast-flowing cooling water generated by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com