Method for rapidly predicting welding seam movement in deep-drawing forming process of laser tailor-welded blank

A technology of forming process and laser tailor welding, applied in the field of weld movement prediction, which can solve the problems of loss of optimization, inability to locate specific materials, and low feasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

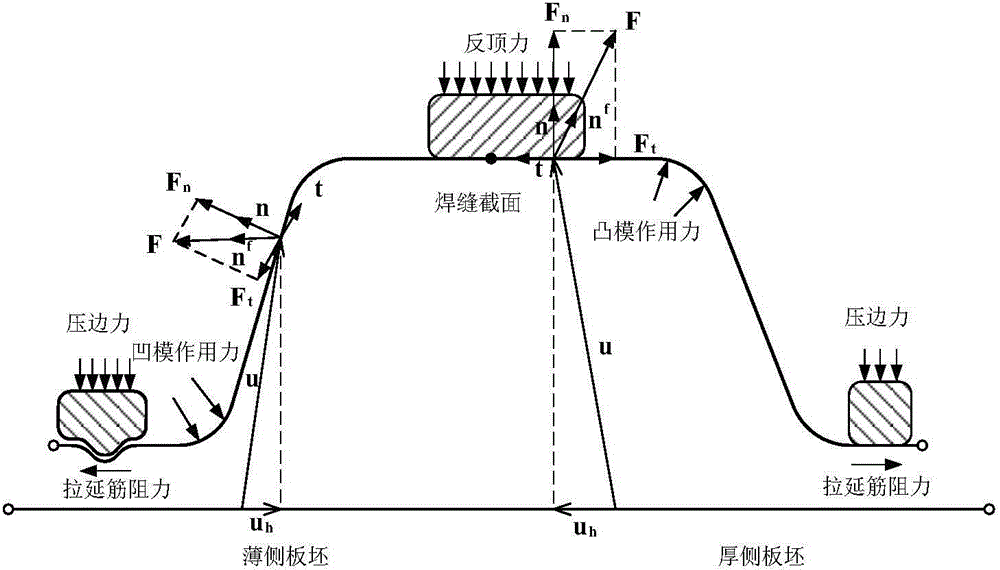

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Quickly obtain the welding line position of the blank

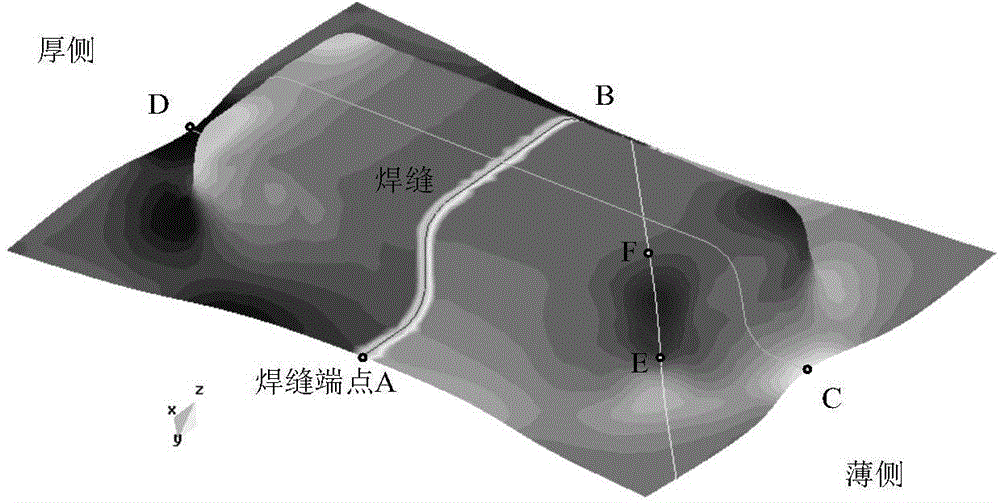

[0061] figure 2 It shows the part diagram after forming, the cross-section AB is the position of the ideal welding seam (without offset), and its end point A is also the reference point for measuring the movement of each point on the welding seam under each working condition. The section line CD is parallel to the length direction of the part, that is, perpendicular to the set weld direction, and is located in the center of the part. This section spans the flange, side wall and bottom weld area of the thick and thin plate side respectively, which can reflect the section The change trend of thickness and strain and the influence of different schemes on it.

[0062] Starting from the deep-drawn parts, the reverse simulation calculation is carried out according to the four schemes shown in Table 1. Schemes 1, 2 and 4 adopt a blank-holding force of 70KN, scheme 3 adopts a blank-holding force of 40KN, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com