Internal and external cooling structure for high-speed motorized spindle

A high-speed motorized spindle and cooling structure technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of increased bearing wear and heat, high temperature, limited heat exchange power, etc., to reduce temperature rise, improve use Longevity, effect of improving machining accuracy and surface finish quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

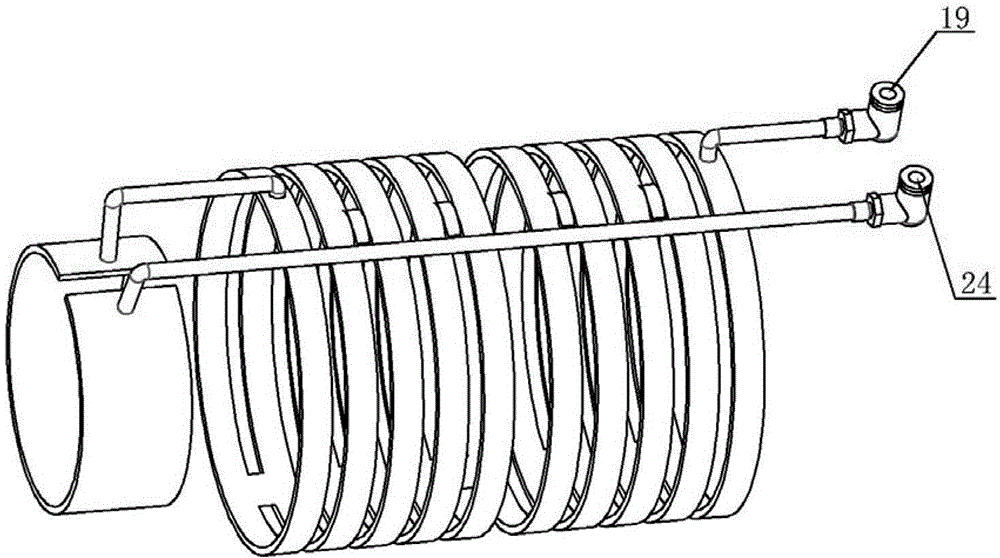

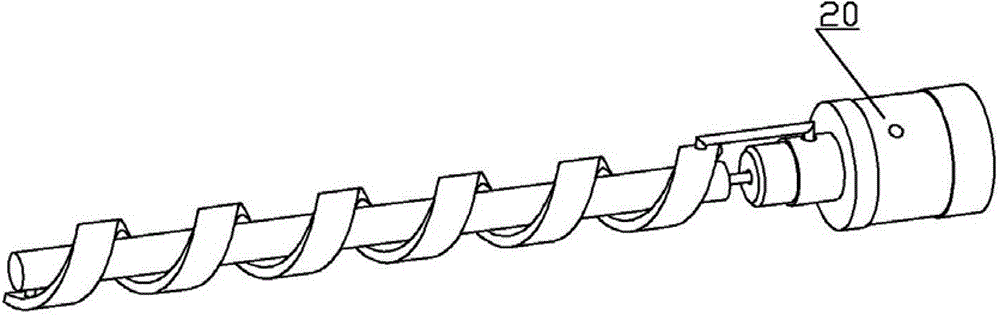

[0021] According to Figure 1 to Figure 4 It can be seen that the cooling structure of the present invention mainly involves: screw 1, transmission key 2, front cover 3, screw 4, housing 5, sealing cover 6, front bearing 7, front bearing seat 8, set screw 9, balance Ring 10, rotor 11, stator 12, set screw 13, rotor nut 14, O-ring 15, main shaft inner water jacket 16, rear bearing seat 17, gland 18, cooling water outlet joint 19, rotary joint 20, code Disk base nut 21, screw 22, code disk 23, cooling water inlet joint 24, code disk base 25, rear bearing nut 26, rear bearing 27, rear bearing retaining ring 28, rotor inner sleeve 29, stator inner water jacket 30, keys 31. Front bearing nut 32, sealing ring 33, O-shaped sealing ring 34, main shaft 35. Wherein the electric spindle front bearing 7 is installed in the front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com