Large steel plate coal house

A steel plate and coal storage technology, applied in the field of storage devices, can solve the problems of reticulated shell rods easy to corrode, safety, large footprint, small reserves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

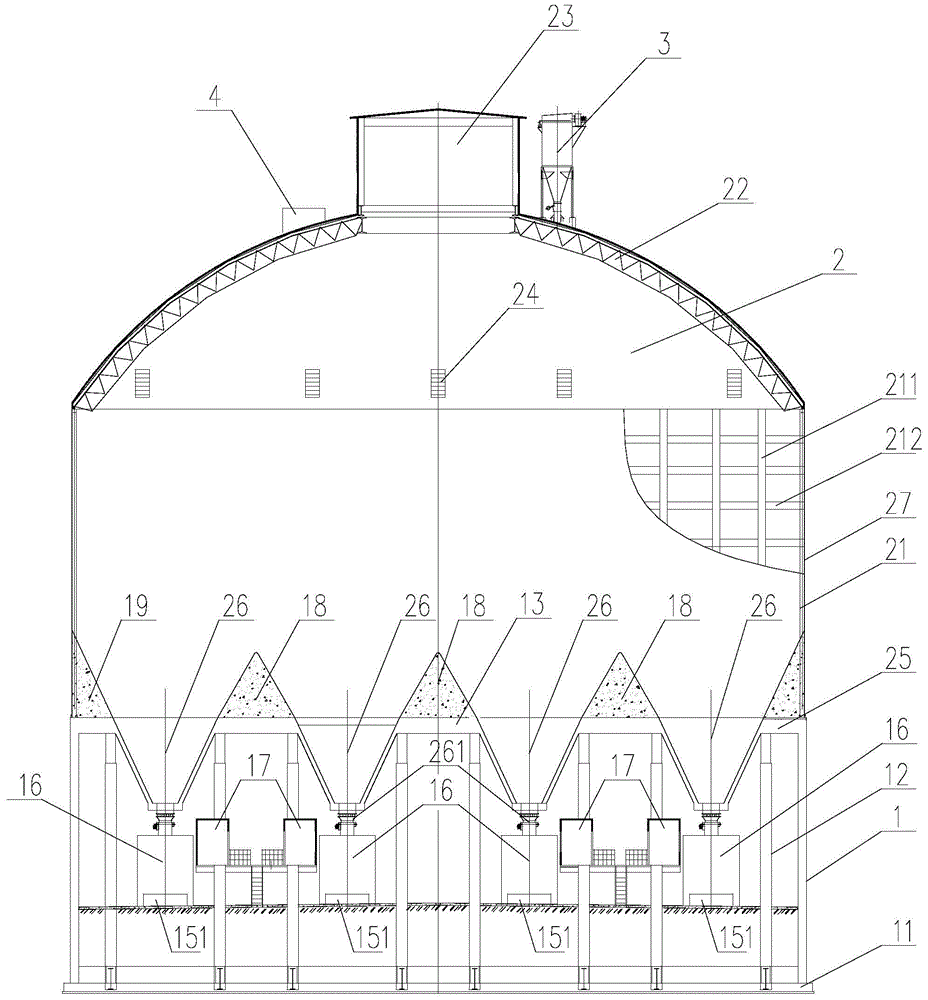

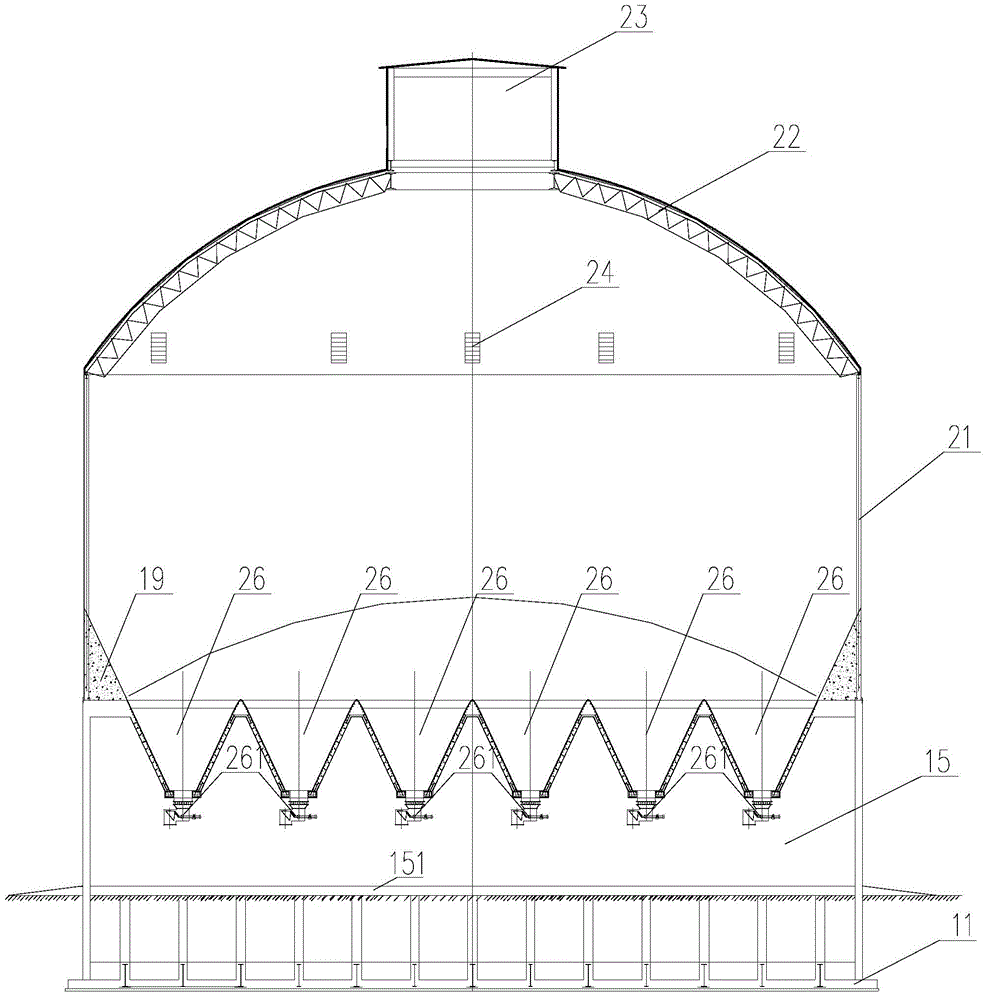

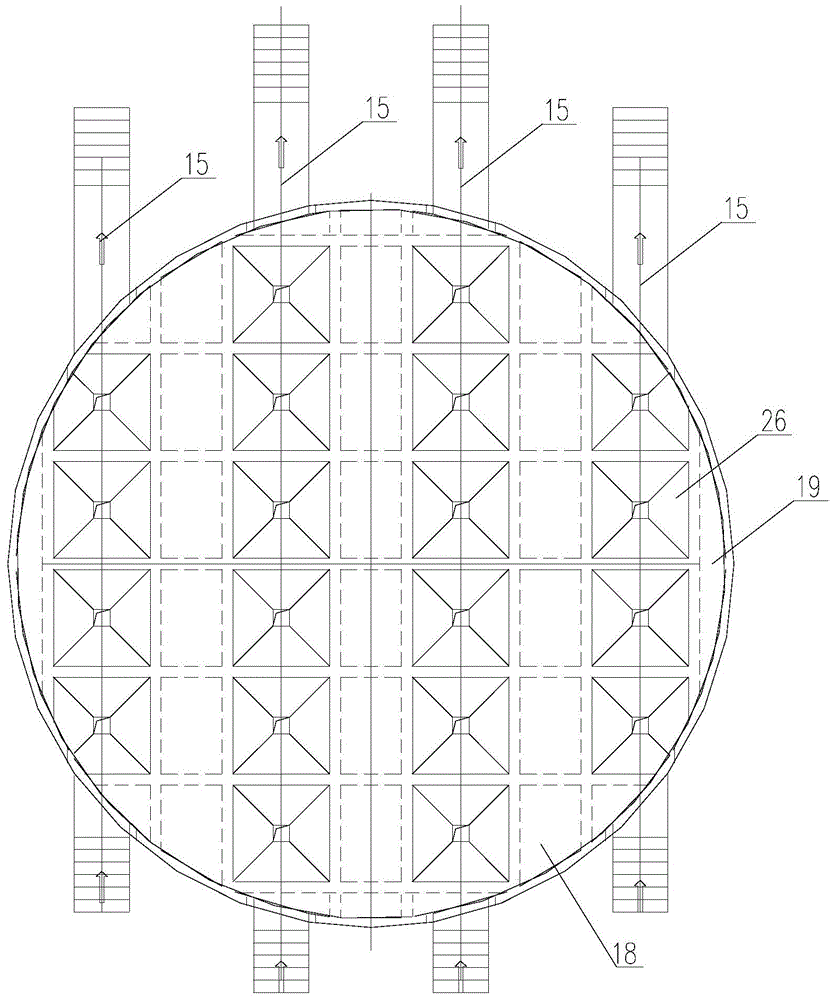

[0026] see Figures 1 to 6 , The large-scale steel plate coal storage of this embodiment includes a coal bunker concrete base 1, a bin body 2, a dust removal device 3, a ventilation device 4, a monitoring device 5 and a coal bunker purge system.

[0027] The base 1 includes a bottom plate 11 , a support column 12 , and a bucket wall 13 . The bottom plate 11 is the foundation of the whole house, more preferably, the bottom plate adopts a reinforced concrete full-slab type full house bottom plate. The support column 12 and the barrel wall 13 supporting the warehouse body on the bottom plate are a frame tube structure, and the surrounding reinforced concrete shear walls form a vertical barrel wall and an internal column frame to form a frame tube with a vertical box-shaped section, forming an overall structure with High stiffness against lateral movement.

[0028] The warehouse body 2 comprises a warehouse bottom 25, a warehouse wall 21, a warehouse roof 22, a rainproof shed 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com