An epoxy resin composition suitable for high voltage surface mount device packaging

A technology of surface mount devices and epoxy resin, which is applied in the field of epoxy resin composition, can solve problems such as damage and electrical performance failure, and achieve the effects of low thermal weight loss rate, high glass transition temperature, and excellent high-voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

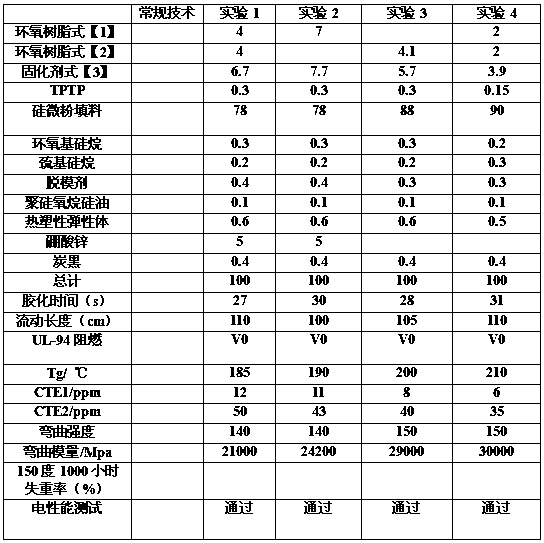

Examples

Embodiment 1

[0029] Example 1, an epoxy resin composition suitable for high-voltage surface mount device packaging, the composition mainly includes: (A) epoxy resin; (B) curing agent; (C) curing agent accelerator; ( D) inorganic filler; (E) coupling agent; (F) stress absorber;

[0030] The (A) epoxy resin is one of the epoxy resins represented by formulas [1] and [2], and its content is 5% of the total mass of the epoxy resin composition;

[0031] The (C) curing agent accelerator is selected from the curing agent accelerator with the structure described in [4], and its content is 0.1% of the total mass of the epoxy resin composition;

[0032] The (B) curing agent is a phenolic resin represented by formula [3], and its content is 5% of the total mass of the epoxy resin composition.

[0033] The remaining raw materials are selected according to the conventional dosage.

Embodiment 2

[0034] Example 2, an epoxy resin composition suitable for high-voltage surface mount device packaging, the composition mainly includes: (A) epoxy resin; (B) curing agent; (C) curing agent accelerator; ( D) inorganic filler; (E) coupling agent; (F) stress absorber;

[0035] The (A) epoxy resin is one of the epoxy resins represented by formulas [1] and [2], and its content is 15% of the total mass of the epoxy resin composition;

[0036] The (C) curing agent accelerator is selected from the curing agent accelerator with the structure described in formula [4], and its content is 2.5% of the total mass of the epoxy resin composition;

[0037] The (B) curing agent is a phenolic resin represented by formula [3], and its content is 15% of the total mass of the epoxy resin composition.

[0038] The remaining raw materials are selected according to the conventional dosage.

Embodiment 3

[0039] Example 3, an epoxy resin composition suitable for high-voltage surface mount device packaging, the composition mainly includes: (A) epoxy resin; (B) curing agent; (C) curing agent accelerator; ( D) inorganic filler; (E) coupling agent; (F) stress absorber;

[0040] The (A) epoxy resin is a mixture of two epoxy resins represented by formulas [1] and [2], and its content is 10% of the total mass of the epoxy resin composition; wherein formula [1] represents The epoxy resin content is 6% of the total mass of the epoxy resin composition;

[0041] The (C) curing agent accelerator is selected from the curing agent accelerator with the structure described in formula [4], and its content is 1.5% of the total mass of the epoxy resin composition;

[0042] The (B) curing agent is a phenolic resin represented by formula [3], and its content is 10% of the total mass of the epoxy resin composition.

[0043] The remaining raw materials are selected according to the conventional dos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com