All-biodegradable modified polylactic acid film-blowing resin and preparation method thereof

A technology of biodegradation and polylactic acid, which is applied in the field of modified polylactic acid blown film grade resin and its preparation, can solve the problems of material tension reduction, cost increase, ductility reduction, etc., and achieve good processing performance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

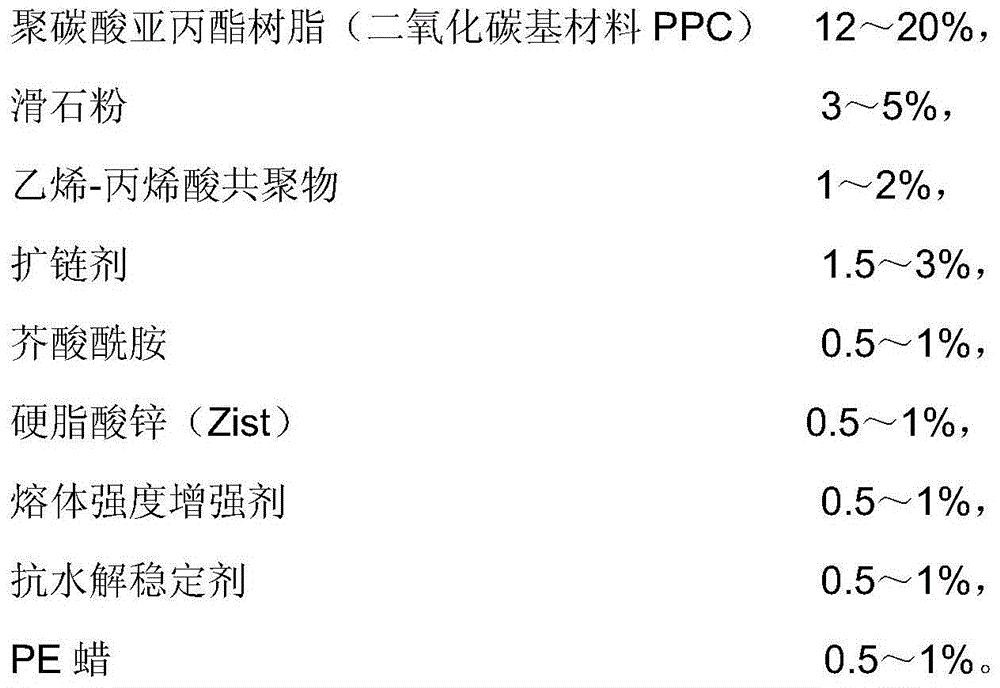

[0026] A fully biodegradable modified polylactic acid blown film grade resin, in terms of weight percentage, the modified polylactic acid blown film grade resin is made of the following components:

[0027]

[0028]

[0029] Prepared according to the following steps:

[0030] Step 1, the polylactic acid (PLA), polyadipate / butylene terephthalate (PBAT), polypropylene carbonate resin (carbon dioxide-based material PPC), talcum powder, ethylene-acrylic acid copolymer, PE Add the wax to a low-speed mixer for stirring and mixing, and then add the required percentage of chain extender, erucamide, zinc stearate (Zist), melt enhancer, anti-hydrolysis stabilizer and then transfer to a high-speed mixer for further mixing. Stir and mix to obtain a mixture;

[0031] Step 2, the mixture in step 1 is divided into 150-250 kg and stirred in separate pots. The stirring time of each pot is 8-10 minutes. It does not need to be heated during stirring. Since the mixer will generate temperat...

Embodiment 2

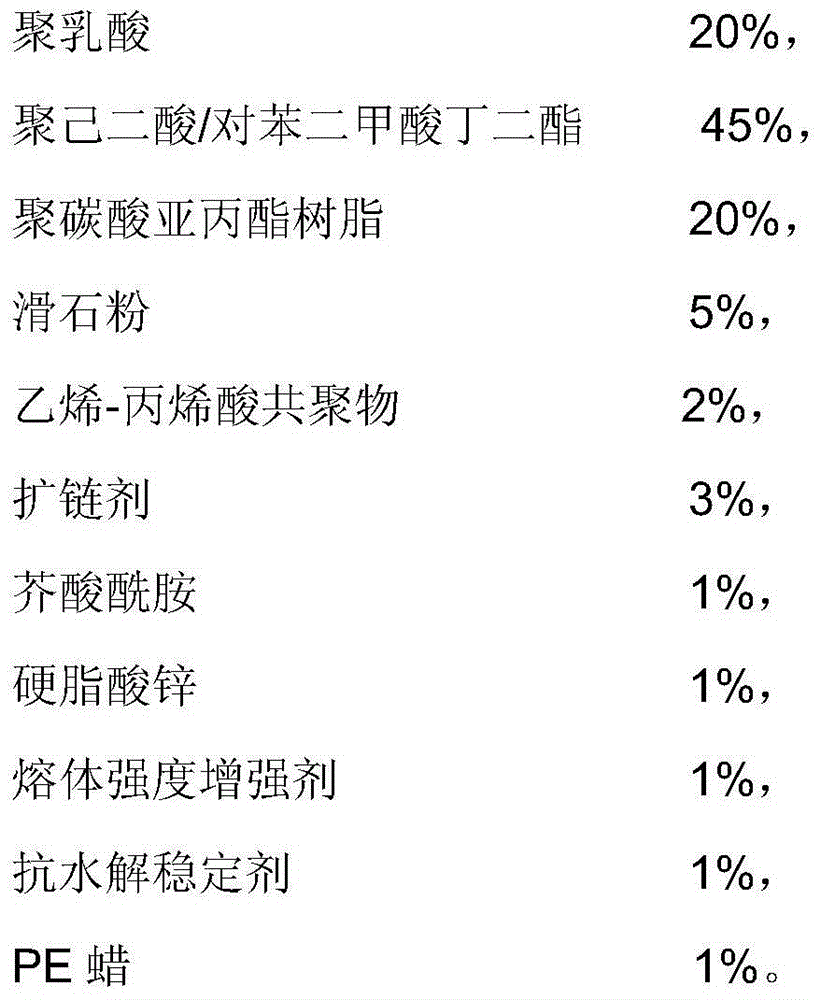

[0036] The difference between this example and Example 1 is that the component distribution ratio of the modified polylactic acid blown film grade resin is different. In terms of weight percentage, the modified polylactic acid blown film grade resin of this example consists of the following components production:

[0037]

[0038] The modified polylactic acid blown film grade resin provided in this example is used to make film products, and the storage time is 18 months at a normal temperature of 23 ° C. There is no change; the biodegradation rate is 93.8% within 90 days under the condition of forced composting.

Embodiment 3

[0040] The difference between this example and Example 1 is that the component distribution ratio of the modified polylactic acid blown film grade resin is different. In terms of weight percentage, the modified polylactic acid blown film grade resin of this example consists of the following components production:

[0041]

[0042] The modified polylactic acid blown film-grade resin provided in this example is used to make film products, and the storage time is 18 months at a normal temperature of 23 ° C. There is no change; the biodegradation rate is 94.6% within 90 days under the condition of forced composting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com