Waste heat recovery device for coke oven raw gas and combined secondary heat extraction method

A waste heat recovery device and waste heat recovery technology are applied in the heating of coke ovens, the discharge device of dry distillation gas, and coke ovens, etc., which can solve the problems of complex composition of waste gas in industrial coke ovens, waste of water resources and electricity, and periodic temperature changes. , to reduce safety risks, reduce steam pressure fluctuations, and reduce the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

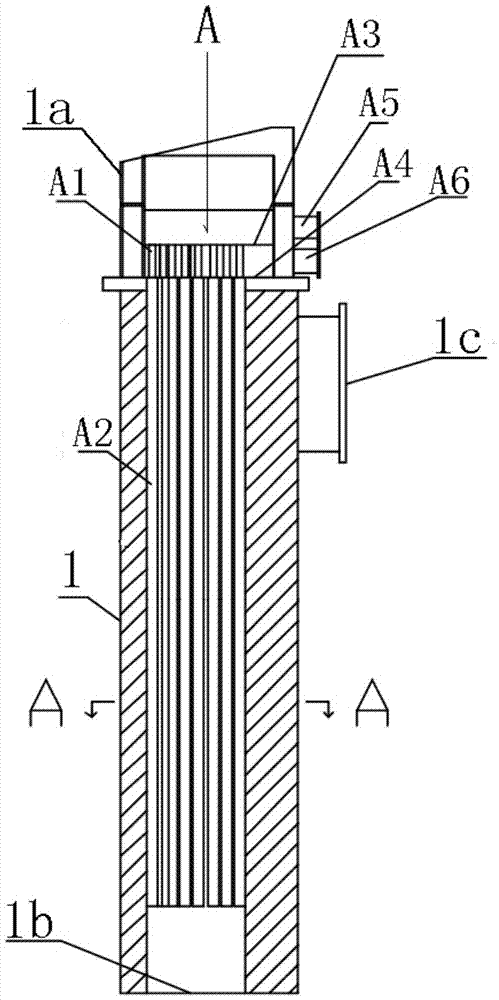

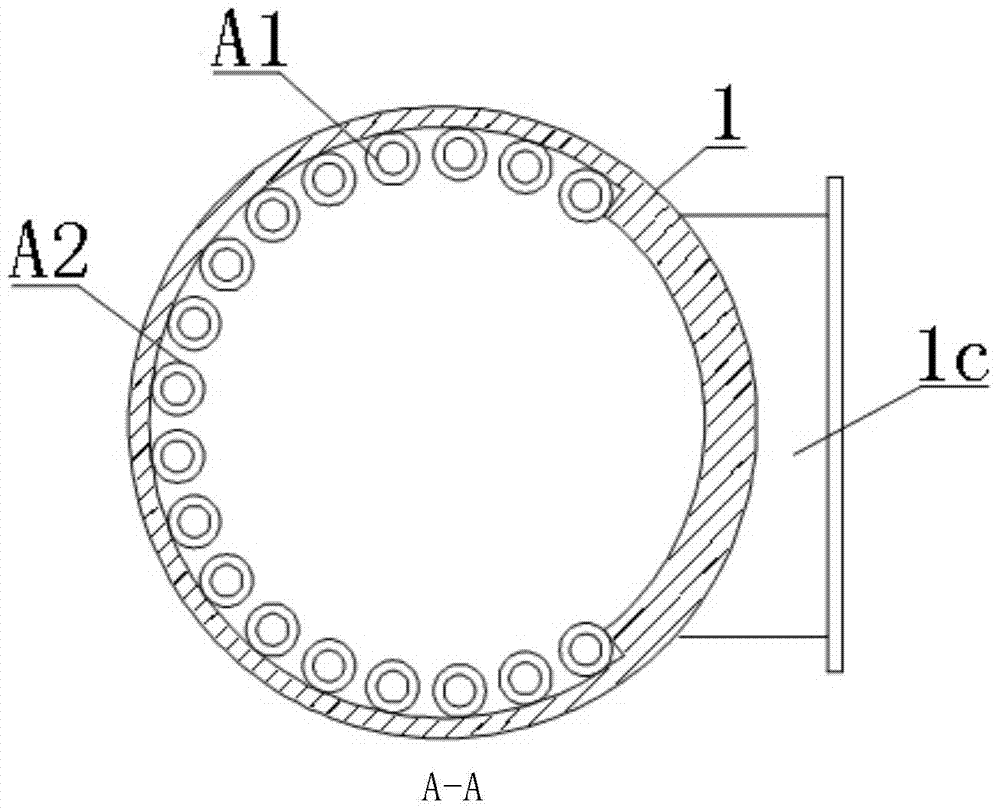

[0061] On a 50-hole coke oven, there are 50 coke oven risers 1 in total, and the sequence of coke pushing is arranged according to "5-2" (that is, coke ovens with an interval of 5 are listed as a group) as follows: the first sequence 1 , 6, 11, 16, 21, 26, 31, 36, 41, 46; the second sequence 2, 7, 12, 17, 22, 27, 32, 37, 42, 47; the third sequence 3, 8 , 13, 18, 23, 28, 33, 38, 43, 48; the fourth sequence 4, 9, 14, 19, 24, 29, 34, 39, 44, 49; the fifth sequence 5, 10, 15 , 20, 25, 30, 35, 40, 45, 50.

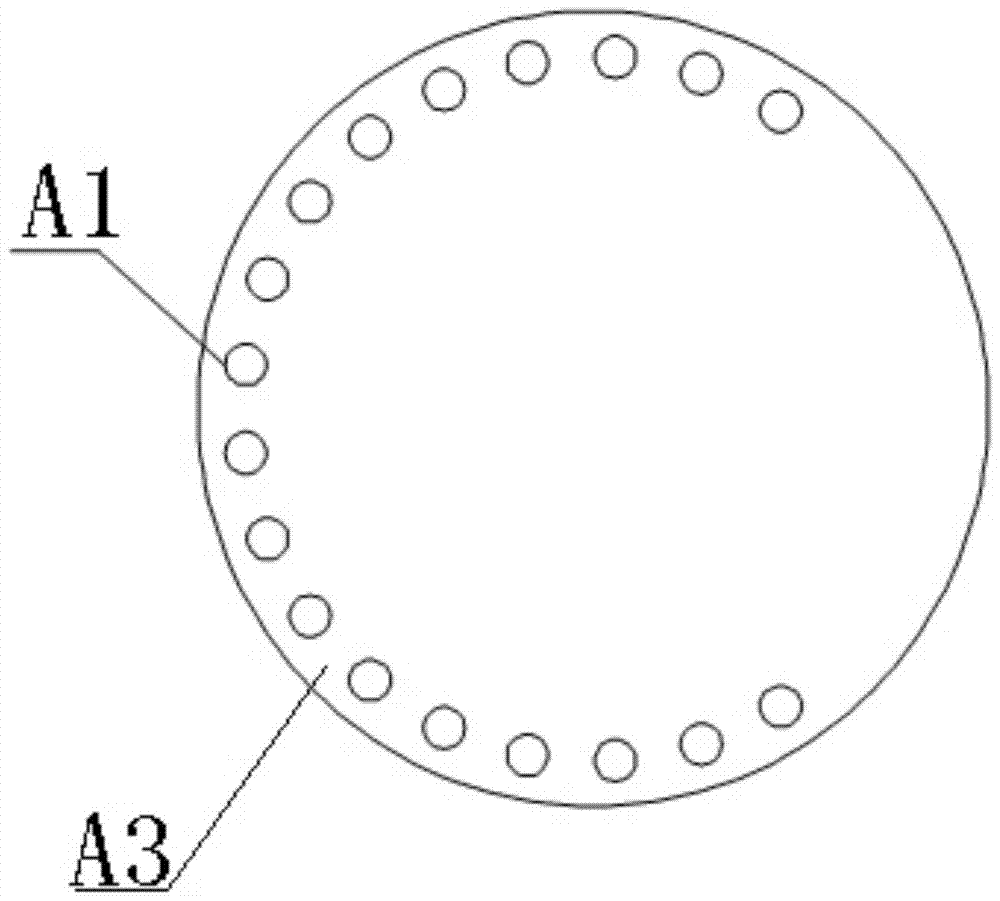

[0062] Each riser is equipped with a waste heat recovery component A, a total of 50 coke oven risers are divided into 5 groups according to the above sequence.

[0063] In this embodiment, hydrogen is used as the primary heat extraction medium. The cold hydrogen enters through the circulation fan 3 first, and the cold hydrogen passes through the heat exchange medium inlet pipe A5 of the waste heat recovery component A of the coke oven riser 1 of the same group and enters the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com