A kind of burner applied in micro-thermal photoelectric system

A micro-thermal photoelectric and burner technology, which is applied in the direction of combustion, combustion type, and combustion method using catalytic materials, can solve the problems of unfavorable energy conversion efficiency of micro-thermal photoelectric system, large temperature difference of outer wall surface, uneven temperature distribution, etc. , to achieve the effect of prolonging the residence time, stabilizing combustion, improving safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

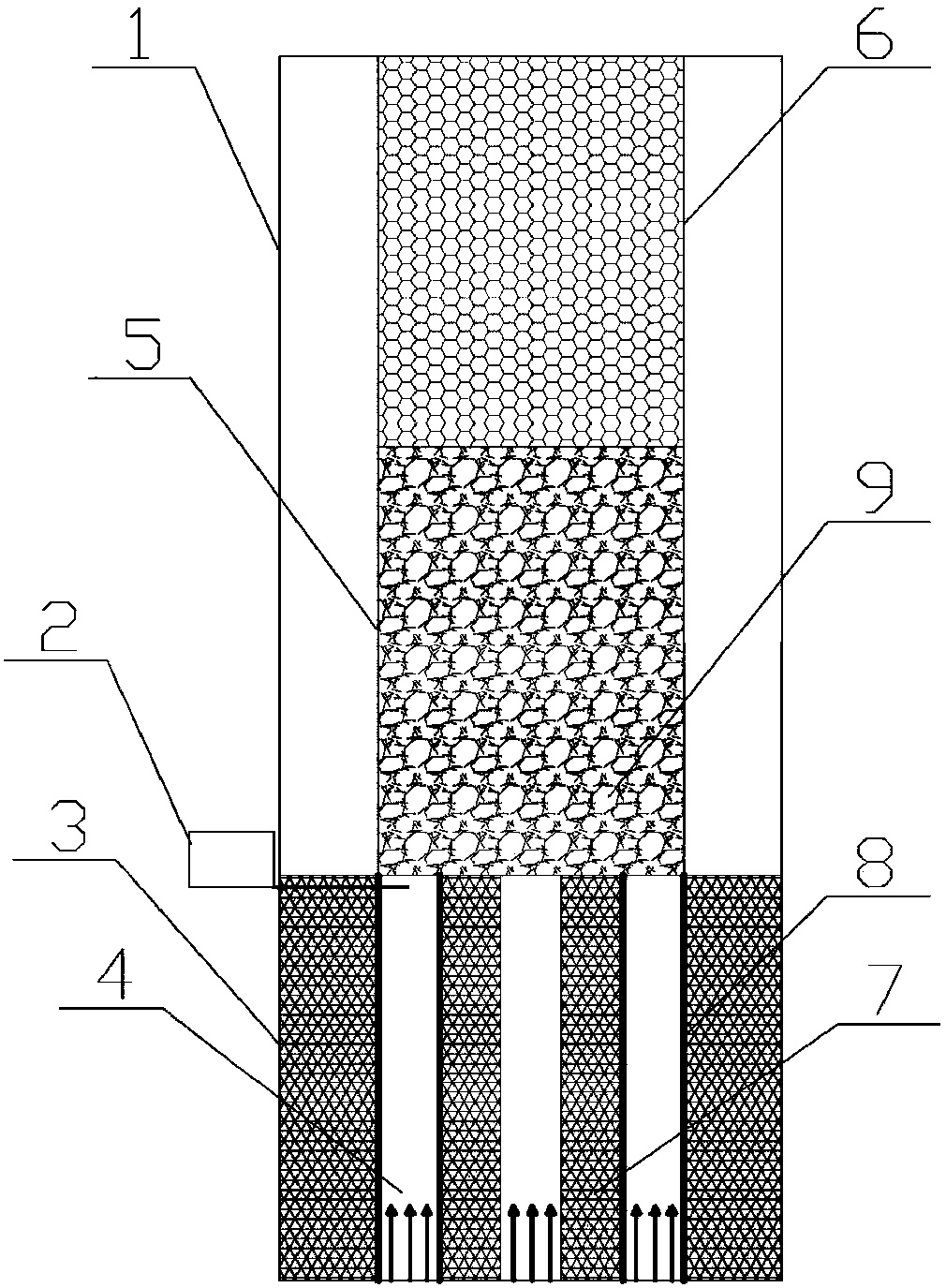

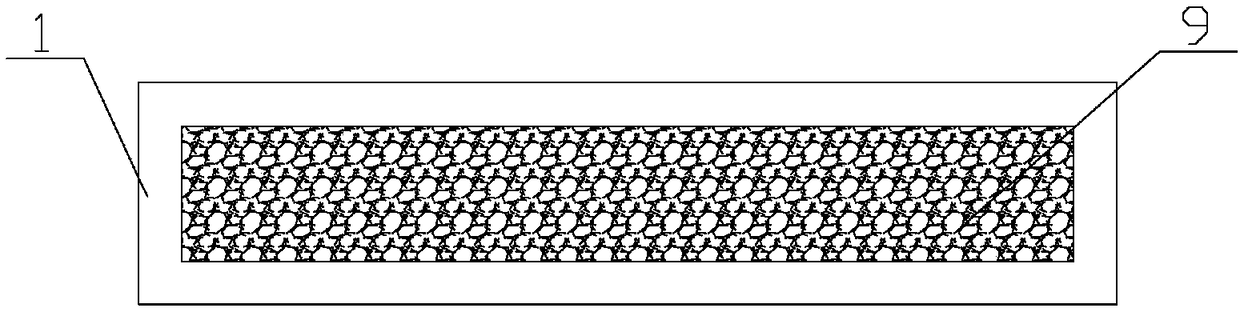

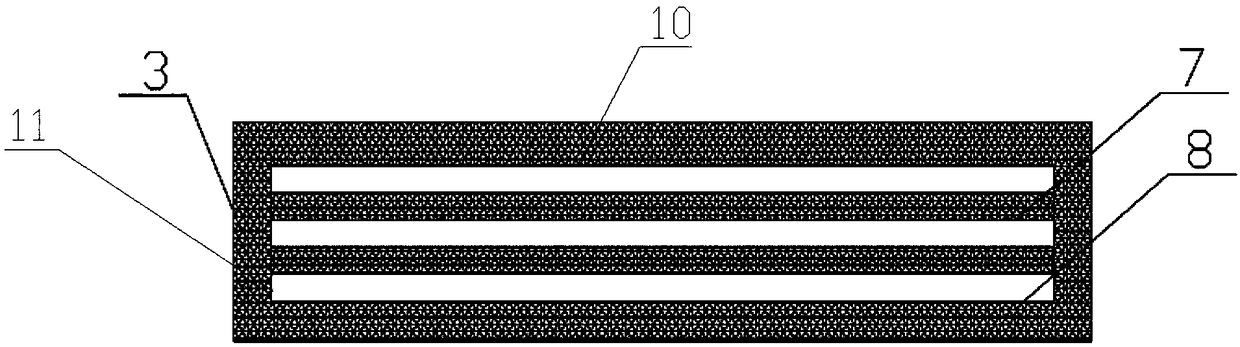

[0030] figure 1 The shown burner applied to the micro-thermal photoelectric system includes an upper part 1 of the combustion chamber, an igniter 2, and a lower part 3 of the combustion chamber; The lower part of the combustion chamber and the upper part of the combustion chamber are made of materials with low thermal conductivity, the lower part of the combustion chamber is made of ceramic material, and the upper part of the combustion chamber is made of high light-transmitting quartz glass; the lower part 3 of the combustion chamber and the upper part 1 of the combustion chamber are cross-sectional It is rectangular; the upper part of the combustion chamber 1 is provided with an exhaust gas treatment area 6 and a porous medium area 5; the filling material in the porous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com