A device and method for reducing high-temperature corrosion of power plant boilers by utilizing waste heat of flue gas

A power plant boiler, high-temperature corrosion technology, applied in the direction of combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problem of increasing the swirl intensity of the internal secondary air, high-temperature corrosion of the side wall water wall, and the burnout rate of pulverized coal Variation and other problems, to achieve the effect of adapting to variable working conditions, high energy grade, and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

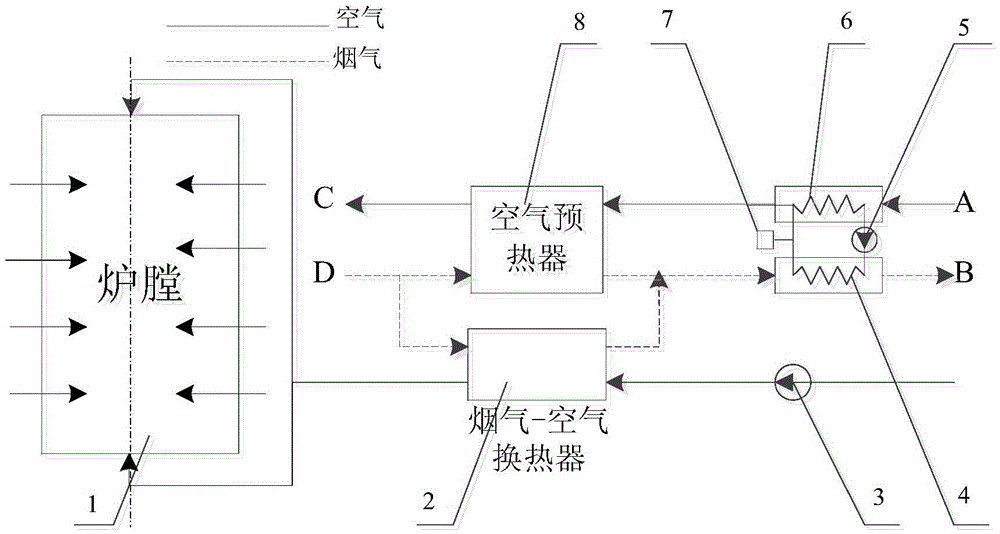

[0027] The device for reducing high-temperature corrosion of power plant boilers by using flue gas waste heat of the present invention includes an air preheater 8, an indirect air preheater connected to the air preheater 8, and a flue gas-air exchanger connected in parallel with the air preheater 8. Heater 2, fan 3 connected to the air inlet of flue gas-air heat exchanger 2. Compared with the original flue gas and air process, this device adds an indirect air preheater, flue gas-air heat exchanger 2, fan 3 and corresponding pipelines.

[0028] Indirect air preheater includes flue gas-oil heat exchanger 4, circulation pump 5, air-oil heat exchanger 6 and expansion tank 7, flue gas-oil heat exchanger 4 heat conduction oil circuit and air-oil heat exchanger The heat conduction oil circuit of 6 is connected through the circulation pump 5 to form a heat exchange circuit; the heat conduction oil pipeline behind the flue gas-oil heat exchanger is provided with an expansion tank 7, an...

Embodiment 2

[0038] In the method of reducing high-temperature corrosion of power plant boilers by using waste heat of flue gas, part of the flue gas discharged from the economizer is diverted into the flue gas-air heat exchanger 2, and the other part enters the air preheater 8. The flue gas entering the flue gas-air heat exchanger 2 heats the air from the fan 3 . After the flue gas is discharged from the flue gas-air heat exchanger 2, it flows into the flue behind the air preheater 8 . The flue gas then enters the flue gas-oil heat exchanger 4 in the indirect air preheater to heat the heat transfer oil. The heat transfer oil is driven by the circulation pump 5 and circulates between the flue gas-oil heat exchanger 4 and the air-oil heat exchanger 6 . The heat transfer oil releases heat in the air-oil heat exchanger 6 to increase the temperature of the inlet primary air and secondary air. The expansion tank 7 is used as a safety device to ensure the normal operation of the heater under c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com