Heat exchange device and garbage disposal system with the same

A technology for heat exchange devices and heat exchange walls, applied in indirect heat exchangers, steam generation methods using heat carriers, lighting and heating equipment, etc., can solve the problem of temperature rise of heat exchange walls, corrosion of heat exchange walls, etc. problems, to achieve the effect of low wall temperature, low corrosion rate and large thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

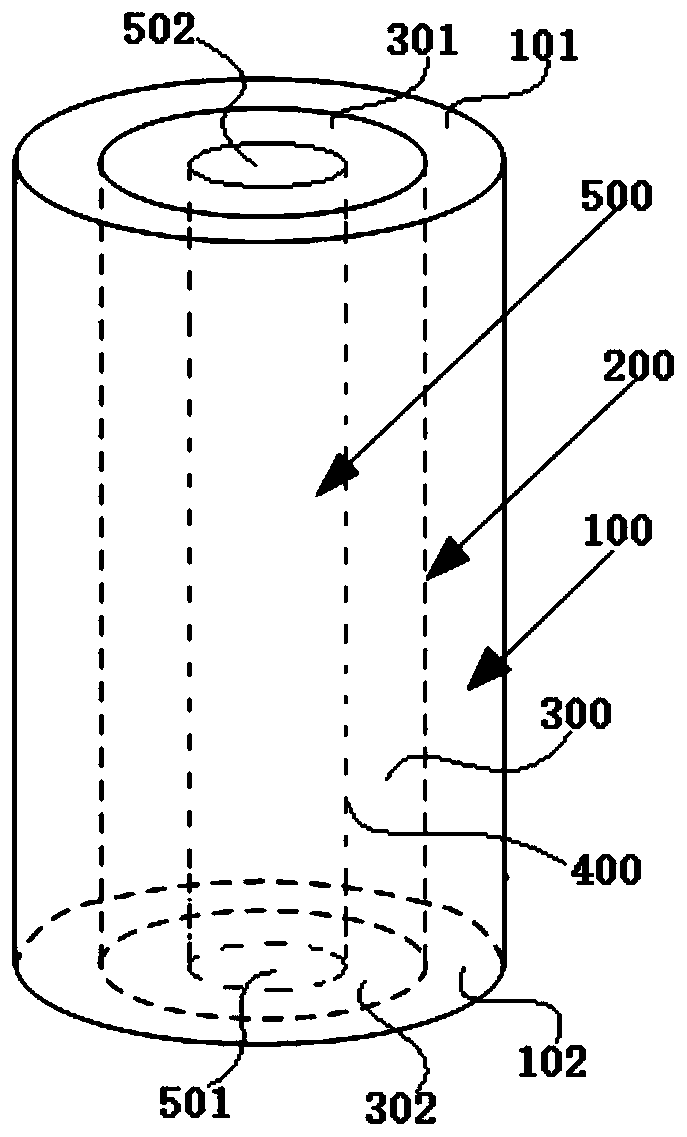

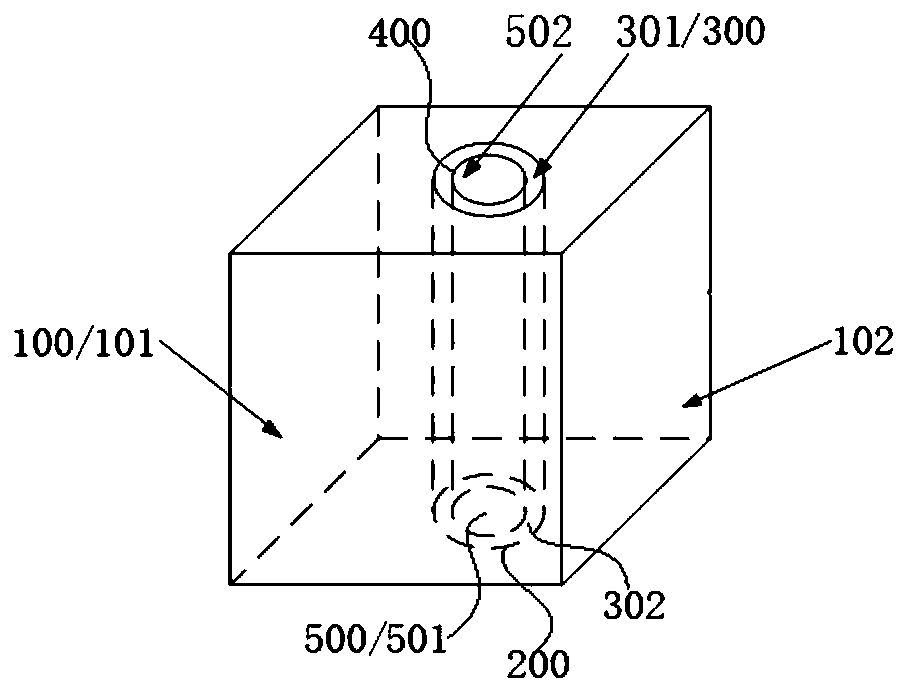

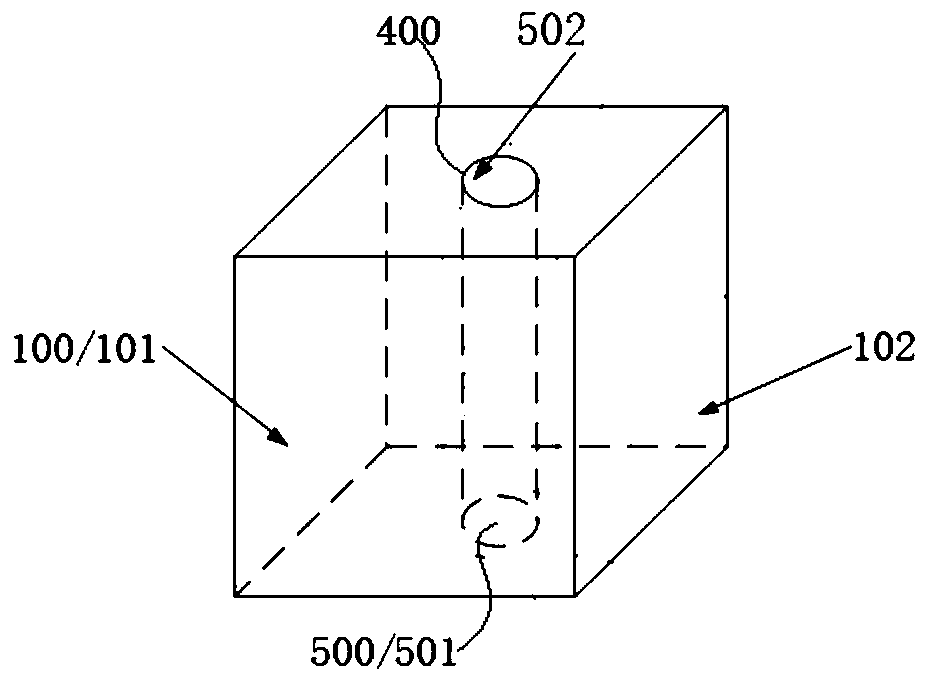

[0047] A sleeve-type heat exchange device, its partial structure schematic diagram is as follows figure 2 shown, including:

[0048] The first medium layer 100, the first medium layer 100 has a first medium inlet 101 and a first medium outlet 102 after heat exchange, the first medium in the first medium layer 100 is flue gas from an incinerator, and its flow rate is 80000Nm 3 / h;

[0049] 20 first heat exchange walls 200, 20 first heat exchange walls 200 are located in the inner periphery of the first medium layer 100, and the outer wall of the first heat exchange wall 200 is connected with the first medium layer 100, the first heat exchange wall The material of 200 is boiler steel 20G, the outer diameter is d o2 =57mm, inner diameter d i2 =49mm, thermal conductivity λ 2 =40W / (m K), the convective heat transfer coefficient h between the flue gas in the first medium layer and the first heat exchange wall o =200W / (m 2 K), length l=1m;

[0050] 20 liquid metal layers 300,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com