Burner with gasification agent and raw coal gas mixed completely and complete mixing and gasification method for gasification agent and raw coal gas

A technology of gasification agent and crude gas, which is used in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

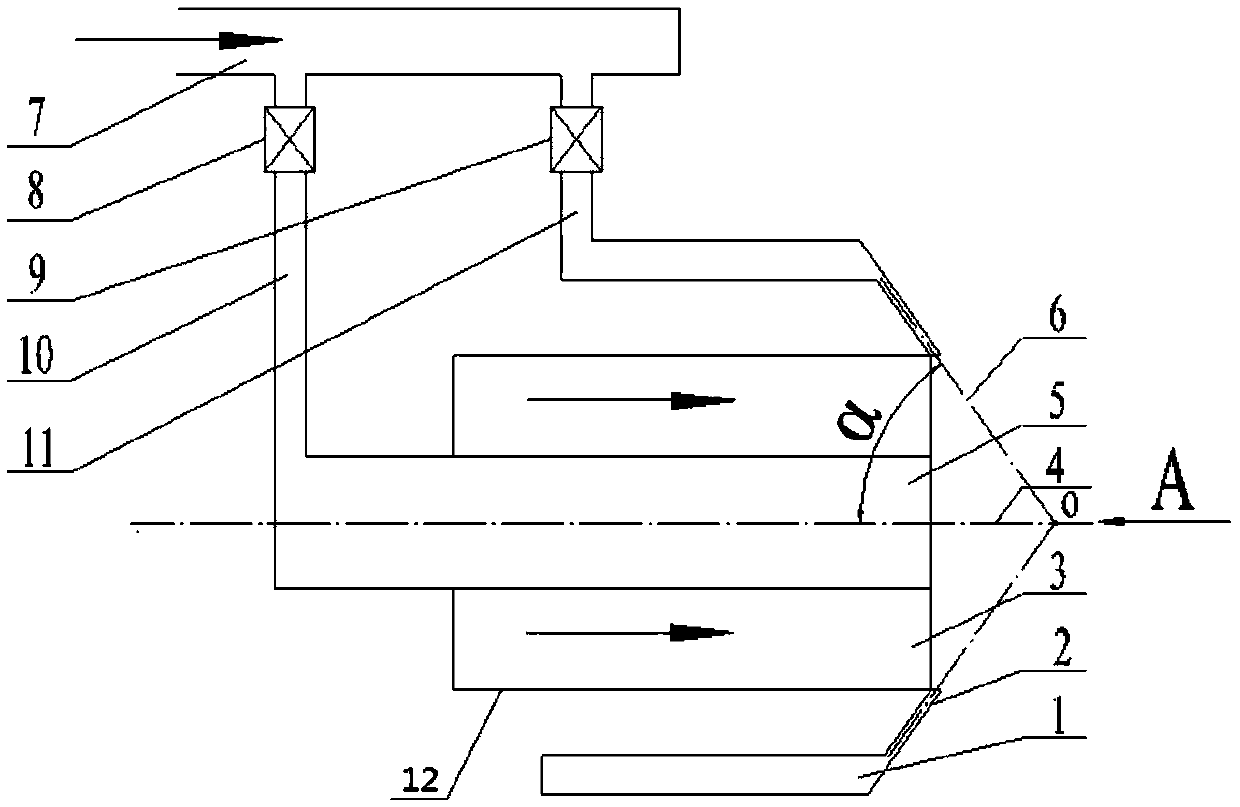

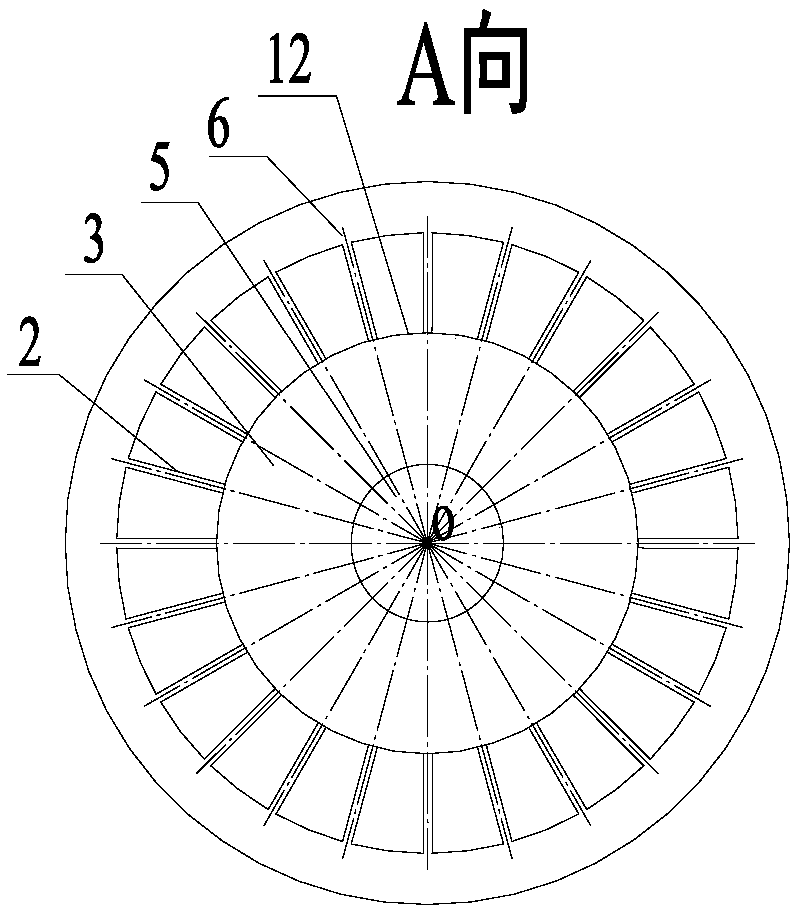

[0037] Specific Embodiment 1: In this embodiment, the gasification agent and crude gas fully mixed burner includes an annular external gasification agent channel (1), an external gasification agent nozzle (2), an annular gasification channel (3), a central gasification agent channel (5), gasification agent main pipe (7), central gasification agent flow regulating valve (8), external gasification agent flow regulating valve (9), central gasification agent delivery pipeline (10) and external gasification Agent delivery pipeline (11);

[0038] Along the radial direction of the burner from inside to outside, the central gasification agent channel (5), the annular gasification channel (3) and the annular outer gasification agent channel (1) are coaxially arranged, and the three channels are parallel to each other;

[0039] The end of the external gasification agent channel (1) close to the gasification chamber of the gasifier is evenly connected with 20 to 60 external gasification ...

specific Embodiment approach 2

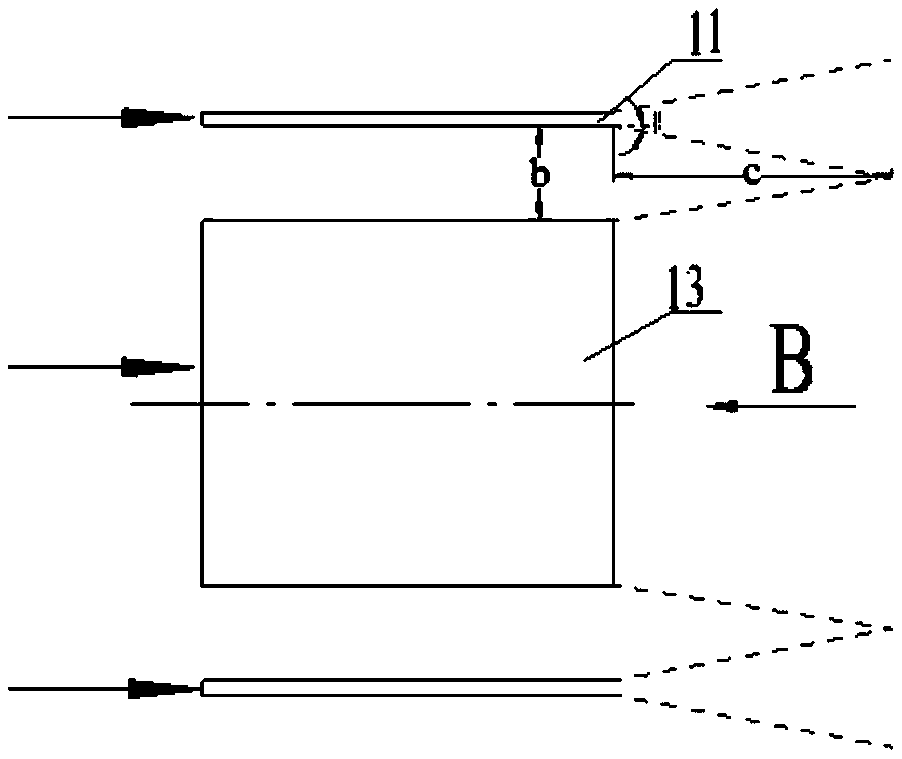

[0043] Embodiment 2: This embodiment differs from Embodiment 1 in that: the external gasification agent nozzle (2) is a circular tube, a regular polygonal tube or an irregular polygonal tube. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment differs from Embodiment 1 in that: the diameters of the equal-area circles in the cross-section of the external gasification agent nozzle (2) are the same or different. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com