Method of preparing MAX phase ceramic coating by using hot spraying

A ceramic coating, thermal spraying technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the problems of low purity and decomposition of the coating, and achieve high purity, low energy consumption, and reduced use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the plasma spraying technology is used to prepare Ti on the surface of 304 steel substrate. 3 AlC 2 Ceramic coating, the specific preparation method is as follows:

[0042] (1) Weigh 30gTi 3 AlC 2 Dissolve the ceramic powder in 500ml deionized water to obtain a powder solution for use;

[0043] (2) Weigh 1g of polyethyleneimine and dissolve it in 100ml of deionized water, stir and dissolve evenly to obtain polyethyleneimine solution for use;

[0044] (3) Measure 30ml of the polyethyleneimine solution prepared in step (2), dissolve it in the powder solution prepared in step (1), and stir evenly with magnetic force to obtain Ti 3 AlC 2 Suspension 1;

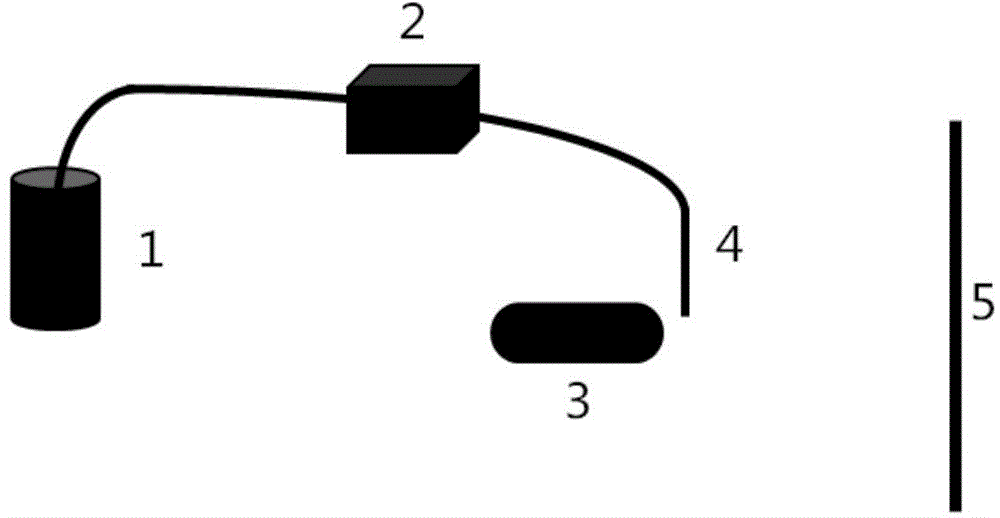

[0045] (4) if figure 1 As shown, using plasma spraying technology, the Ti obtained in step (3) 3 AlC 2 The suspension 1 is sprayed and deposited on the surface of the substrate 5 through the nozzle 4 to form a coating under the power provided by the peristaltic pump 2. The specific spraying param...

Embodiment 2

[0059] In the present embodiment, adopt plasma spray technology, the Ti that steps (1) to (3) in embodiment 1 are prepared 3 AlC 2 The suspension was vertically sprayed into liquid nitrogen through the nozzle under the action of the same peristaltic pump as in Example 1, then dried, and the sprayed dry powder was collected. Among the specific spraying parameters, the ion spraying parameter is 20kw, and the rest of the parameters are exactly the same as those listed in Table 1.

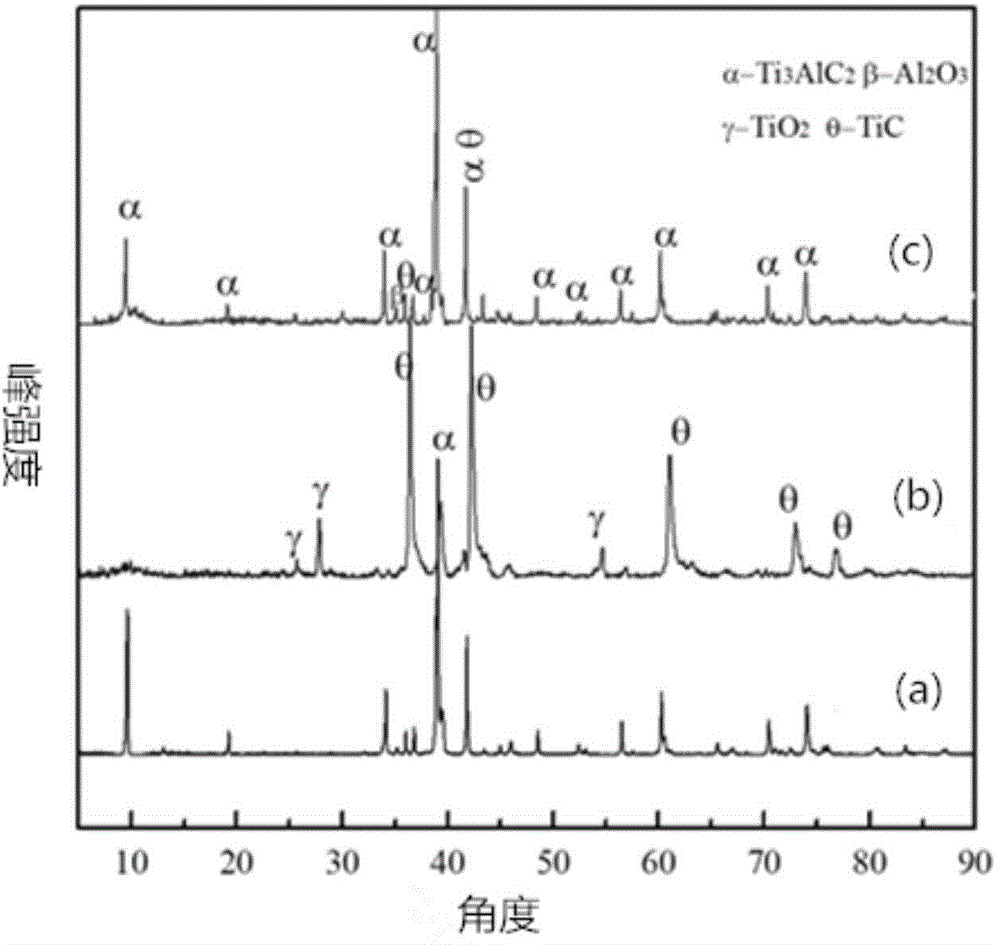

[0060] The dried powder after spraying was analyzed by XRD, Figure 4 It is the XRD diffraction pattern of the powder, obtained through the XRD diffraction peak: the main peak intensity is Ti 3 AlC 2 , and a small amount of TiC and Al 2 o 3 . By semi-quantitative calculation: Ti in the sprayed powder 3 AlC 2 The phase content is about 65%, indicating that the Ti 3 AlC 2 The phase accounts for the vast majority, and this method can prepare relatively pure Ti 3 AlC 2 coating.

[0061] Compar...

Embodiment 3

[0063] In this embodiment, the plasma spraying technology is used to prepare Ti on the surface of 304 steel substrate. 3 AlC 2 +20% Al ceramic coating, the specific preparation method is as follows:

[0064] (1) Weigh 40gTi 3 AlC 2 Powder ceramics, then weigh 8g of Al powder, mix the two, add ethanol to it, then put it into a planetary ball mill, ball mill and mix evenly to get Ti 3 AlC 2 Mixed powder with Al powder, where Al powder accounted for Ti 3 AlC 2 20% of powder mass;

[0065] (2) Preparation of Ti 3 AlC 2 +20% Al powder suspension:

[0066] Concrete steps are the same as steps (1)~(3) in embodiment 1, only difference is the Ti in embodiment 1 step (1) 3 AlC 2 The Ti obtained in the above steps (1) is used for the powder 3 AlC 2 Replaced with the mixed powder of Al powder, what is produced in step (3) is Ti3 AlC 2 +20% Al powder suspension;

[0067] (3) using plasma spraying technology, the Ti obtained in step (2) 3 AlC 2 The +20% Al powder suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com