Solvent-assisted sagd three-dimensional physical simulation experiment method and experimental device

A simulating experimental device, a technology of three-dimensional physics, applied in the field of oil production, can solve the problems of lack of perfect unified solvent-assisted SAGD injection and production equipment, no physical simulation method, low driving energy in the huff and puff stage, etc., so as to avoid insufficient steam energy. , Effective and simple separation and recovery, the effect of strong ability to avoid risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

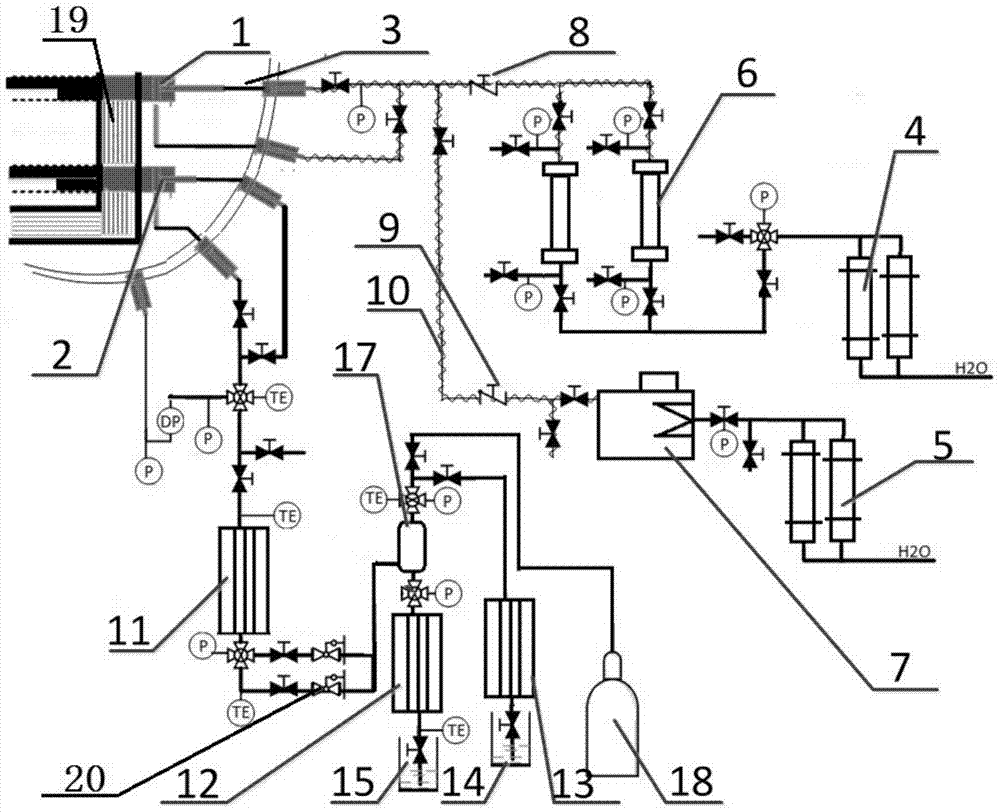

[0055] This embodiment provides a solvent-assisted SAGD three-dimensional physical simulation experimental device, such as figure 1 As shown, the experimental device includes an injection device, a simulated reservoir model and a recovery device, and the injection device and the recovery device are respectively connected with the steam injection well 1 and the production well 2 of the simulated reservoir model.

[0056] The simulated reservoir model includes a thin-walled model body 19, a steam injection well 1, a production well 2 and a hyperbaric chamber 3; the thin-walled model body 19 is set inside the hyperbaric chamber 3, and the steam injection well 1 and the production well 2 are horizontally drilled into the thin-walled The model body 19 forms double horizontal wells, and the steam injection well 1 and the production well 2 communicate with the outside world through parallel double holes on the high pressure bulkhead. Holes for pressurization are provided on the wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com