A full-bore hydraulically driven layered fluid injection and fracturing device

A full-bore, hydraulic technology, used in wellbore/well valve devices, production fluids, wellbore/well components, etc., can solve the problems of difficult operation, complex process, inability to inject different liquids, etc. Clear, simple installation and crafting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

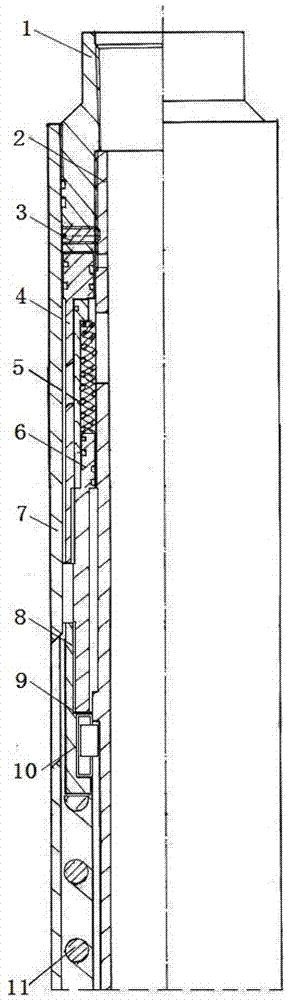

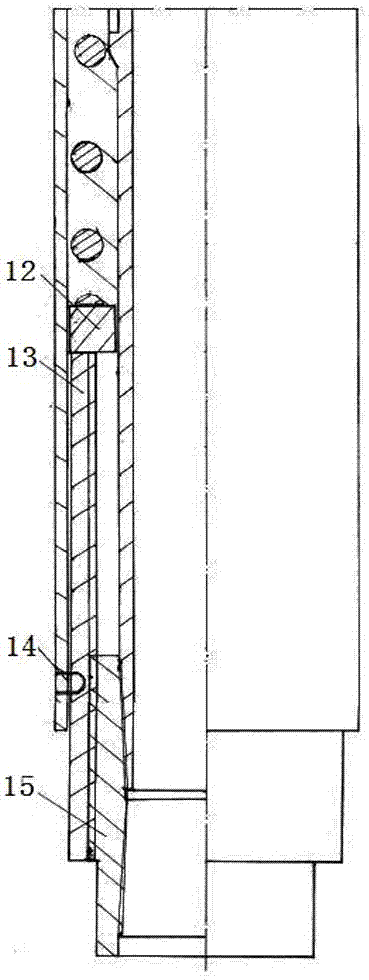

[0022] Embodiment 1: A full-bore hydraulically driven layered liquid injection and fracturing device mentioned in the present invention, including an upper joint 1, a central pipe 2, a sealing piston 4, a constant pressure switch 5, a single-flow slideway body 6, Sealing cylinder liner 7, conversion pressure cap 8, swivel 9, track pin 10, energy storage mechanism 11, energy storage pad 12, pressure adjustment ring 13, positioning pin 14, lower joint 15, between upper joint 1 and lower joint 15 Connected by the central tube 2, the upper joint 1 and the lower joint 15 are provided with a sealed cylinder liner 7, and the center tube 2 and the sealed cylinder liner 7 are sequentially provided with a sealed piston 4, a constant pressure switch 5, and a single flow valve. Slideway body 6, swivel pressure cap 8, swivel ring 9, sealing piston 4, constant pressure switch 5, single flow slideway body 6, swivel pressure cap 8, swivel 9 form a moving body, sealing piston 4 and central tube...

Embodiment 2

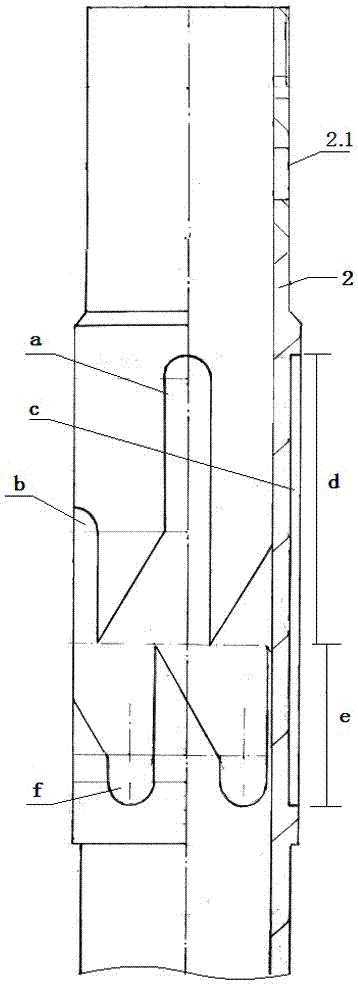

[0031] Embodiment 2: Different from Embodiment 1, the constant pressure switch 5 is canceled, a miniature constant pressure switch is set on the sealing piston 4, a miniature constant pressure switch is set on the single-flow slide body, and an opening is provided on the top of the sealing piston. Slots, springs and balls are arranged inside the slots, diversion grooves are provided at the bottom of the single-flow slide body, and springs and balls are arranged inside the diversion grooves to realize communication, thereby realizing the function of liquid injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com