Accelerating agent quantitatively-adding dry-wet dual purpose concrete spraying machine

A concrete spraying machine, wet and dry dual-purpose technology, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of construction delay, impact on construction progress, strength loss, etc., to reduce the amount of dust and rebound, Realize the effect of reusing and reducing the sealing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

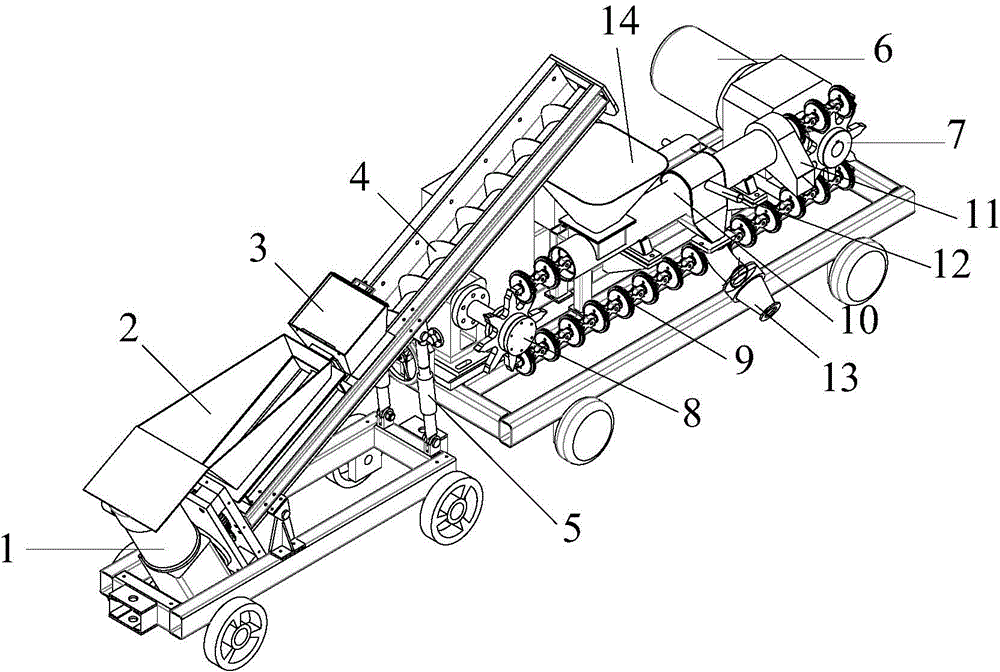

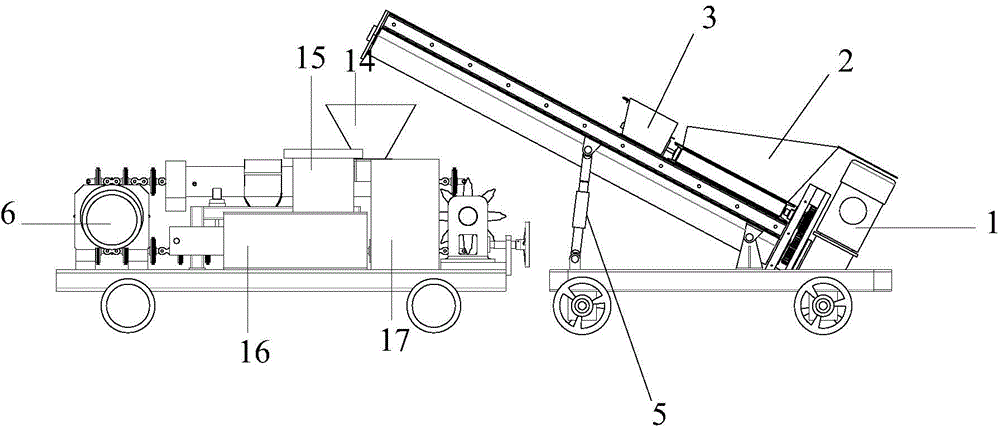

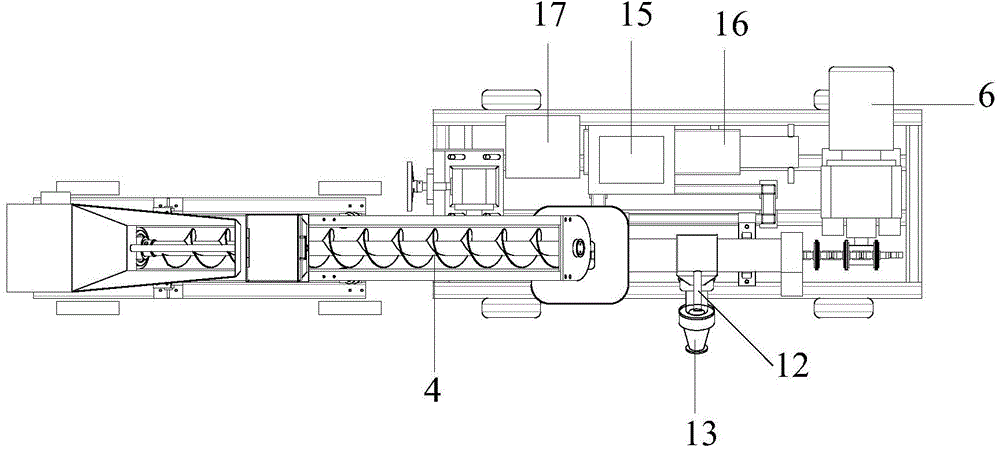

Embodiment 1

[0047] The control box controls the rotation of the first motor, and the first motor drives the conveying auger to rotate around the axis of the conveying auger, adding concrete mixture to the concrete hopper 2, adding powdered quick-setting agent to the powdered quick-setting agent hopper 3, After the two are mixed in the conveying auger 4, they enter the feeding hopper 14 in the injection system. The control box controls the rotation of the second motor, and the second motor drives the driving sprocket to rotate through the second motor reducer, and then drives the serial piston parts to rotate. , the concrete mixture enters the sealed chamber from the feeding hopper under the movement of the series piston parts, and the high-pressure air blows the concrete mixture out of the discharge port 13 through the air inlet, the second air inlet pipe and the third air inlet pipe , the concrete mixture that cannot be blown out is discharged through the tail material deflector, the conc...

Embodiment 2

[0049] The control box controls the rotation of the first motor, and the first motor drives the conveying auger to rotate around the axis of the conveying auger, adding concrete to the concrete hopper 2, and the concrete is conveyed by the conveying auger 4 to the feeding hopper 14 in the injection system, the control box 17 Control the rotation of the second motor, the second motor drives the driving sprocket to rotate through the second motor reducer, and then drives the series piston parts to rotate, the concrete mixture enters the sealed chamber from the feeding hopper under the movement of the series piston parts, and the high pressure The wind blows the concrete mixture out of the discharge port 13 through the air inlet, the second air inlet pipe and the third air inlet pipe, and the concrete mixture that cannot be blown out is discharged through the tail material deflector, and the liquid quick-setting agent silo The liquid accelerator is filled and flows into the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com