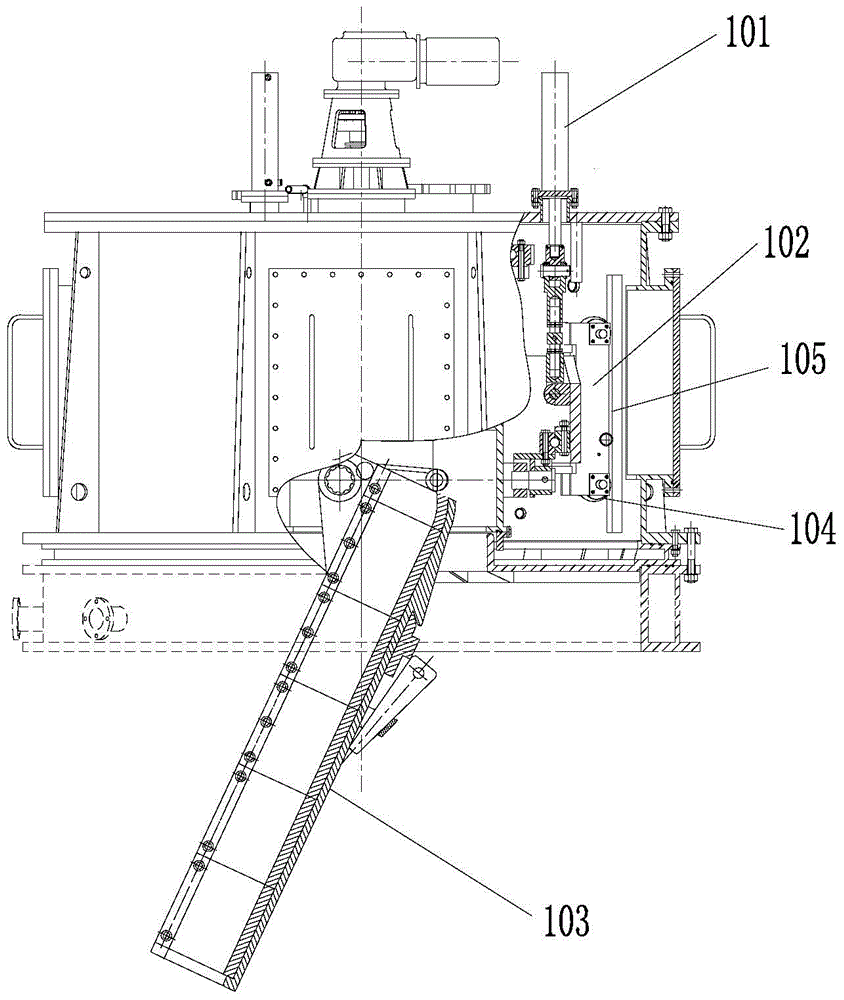

Hydraulic control system for cloth chute inclination positioning accuracy

A technology of hydraulic control system and distributing chute, which is applied to fluid pressure actuating device, blast furnace parts, bell and funnel arrangement, etc., can solve the problems of increased wear, increase, and inability to meet blast furnace process requirements, and achieves improved control Accuracy, uniform cloth surface, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

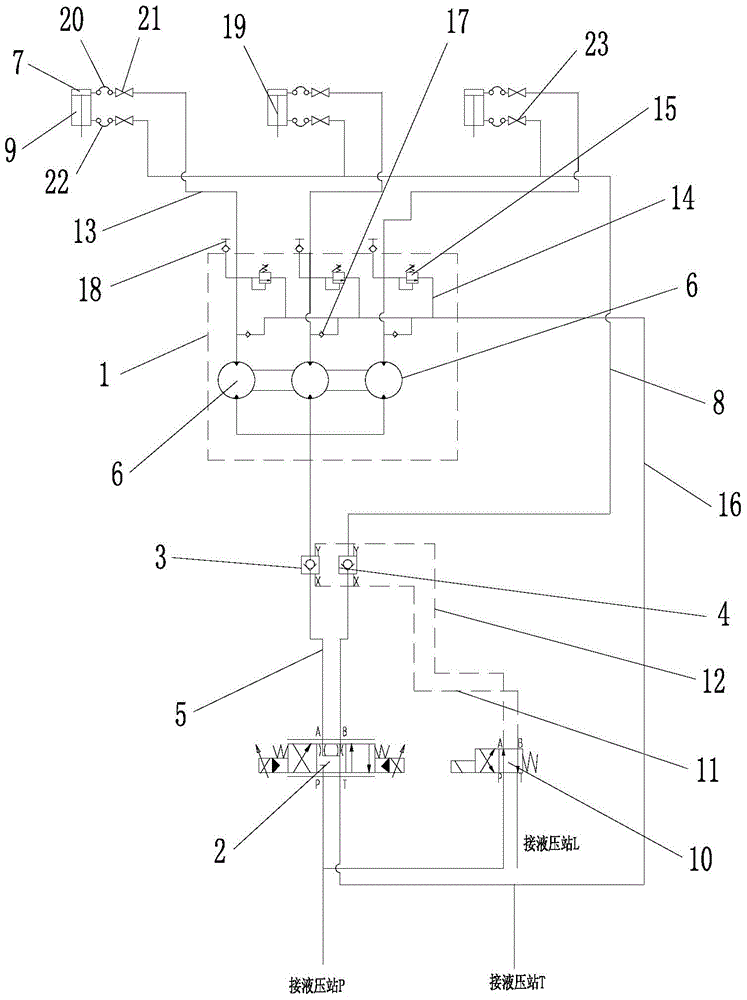

[0040] Such as figure 2 As shown, the hydraulic control system for the inclination positioning accuracy of the distribution chute of the present invention includes a hydraulic synchronous motor 1 , a proportional valve 2 , a first hydraulic control check valve 3 and a second hydraulic control check valve 4 . The proportional valve 2 in this embodiment adopts a three-position four-way electro-hydraulic proportional valve, and of course other types of proportional valves can be used as long as the same function can be realized, such as a servo proportional valve. Proportional valve 2 has the functions of stepless speed regulation and precise control of oil supply, and can precisely position the distribution chute. The oil port P of the proportional valve 2 is connected with the high-pressure hydraulic oil source. figure 2 The oil port P of the proportional valve 2 is connected to the hydraulic station P, that is, the high-pressure oil pump is used to convert the low-pressure ...

Embodiment 2

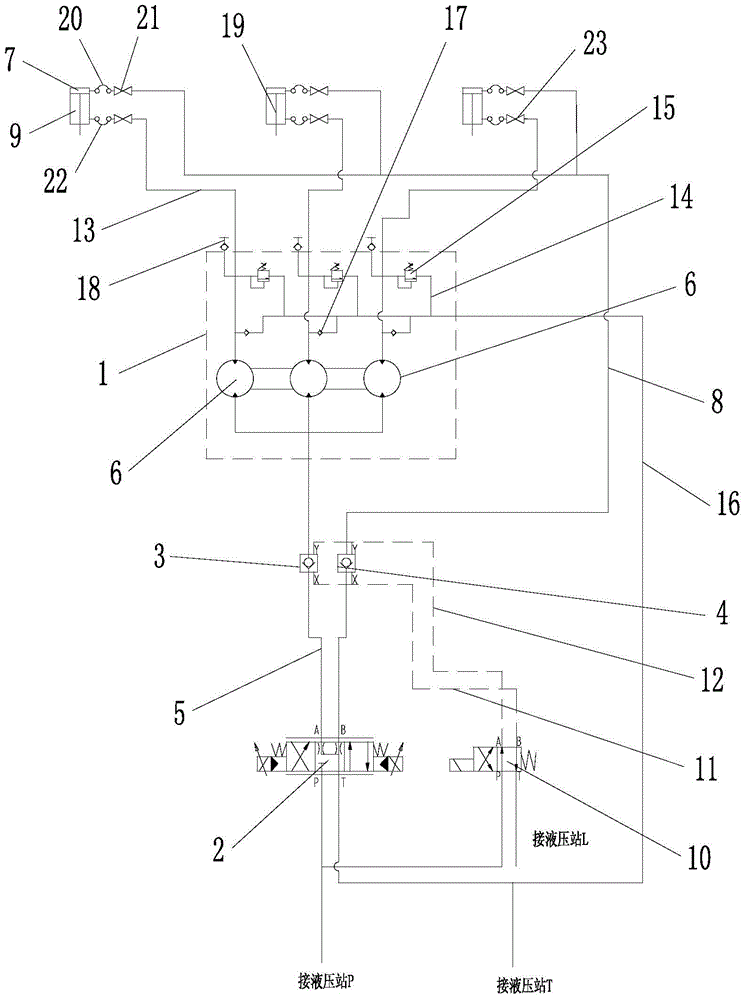

[0052] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the three shunt oil pipes 13 are respectively connected with the three rod chambers 9 of the oil cylinder, and the three-way branches of the second pipeline 8 are respectively connected with the rodless chambers of the three oil cylinders. 7 connections. The structures and working principles of other parts are completely the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com