Separator with low noise device

A low-noise, separator technology, applied in the field of separators to reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

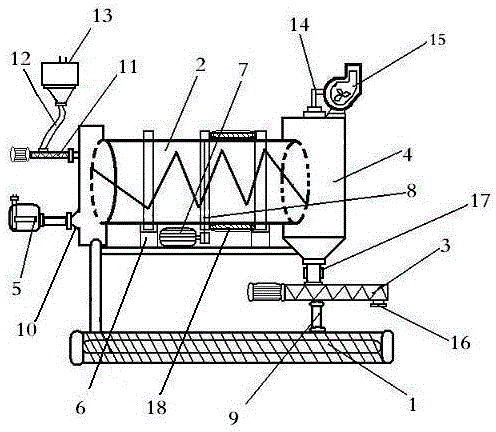

[0013] Example: such as figure 1 As shown, a separator of a low-noise device in this example includes a frame (1), a dryer (2), a first screw conveyor (3), Cyclone dehumidifier (4), hot air stove (5), the dryer (2) and the frame (1) are connected by rollers (6), and the lower end of the dryer (2) is provided with a driving motor (7), the drive motor (7) is connected to the dryer (2) through a belt strip (8), and one end of the dryer (2) is connected to the cyclone dehumidifier (4), and the cyclone The lower end of the dehumidifier (4) is connected with the first screw conveyor (3), the first screw conveyor (3) is fixed to the frame (1) through the support rod (9), and the hot blast stove (5 ) is fixed on the left lower end of the dryer (2) through a screw (10), the upper left end of the dryer (2) is connected to the second screw conveyor (11), and the second screw conveyor (11) passes through The feeding pipe (12) is connected to the hopper (13). When in use, wet pig manure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com