Optical fiber end surface reflecting mirror packaging method

A technology of optical fiber end face and packaging method, which is applied in the coupling of optical waveguide and other directions, can solve the problem of small size, and achieve the effect of small size, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

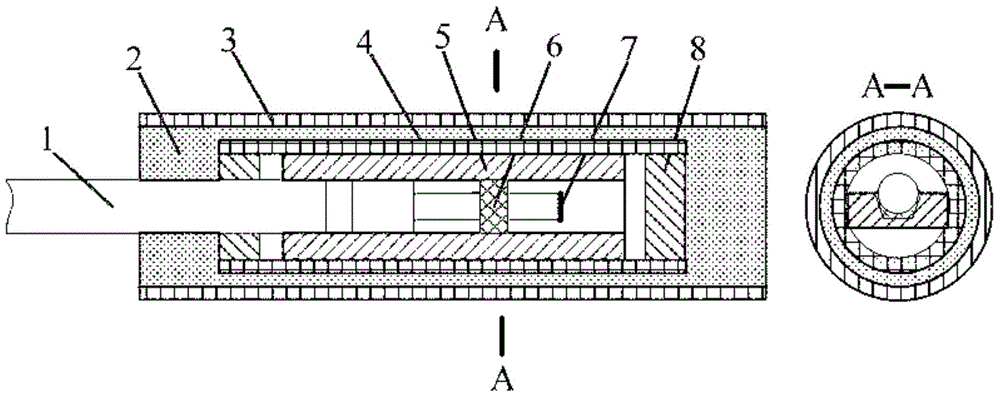

[0026] A packaging method for an optical fiber end reflector, the schematic diagram of the packaging structure of the optical fiber end reflector of the present invention is as follows figure 1 shown. In the figure, 1 is the optical fiber output end, 2 is the packaging glue (704 glue), 3 is the tempered glass tube, 4 is the quartz capillary tube, 5 is the quartz plate, 6 is the first fiber fixing glue (353ND glue), 7 is the anti-increasing Film, 8 is the second optical fiber fixing glue (353ND glue).

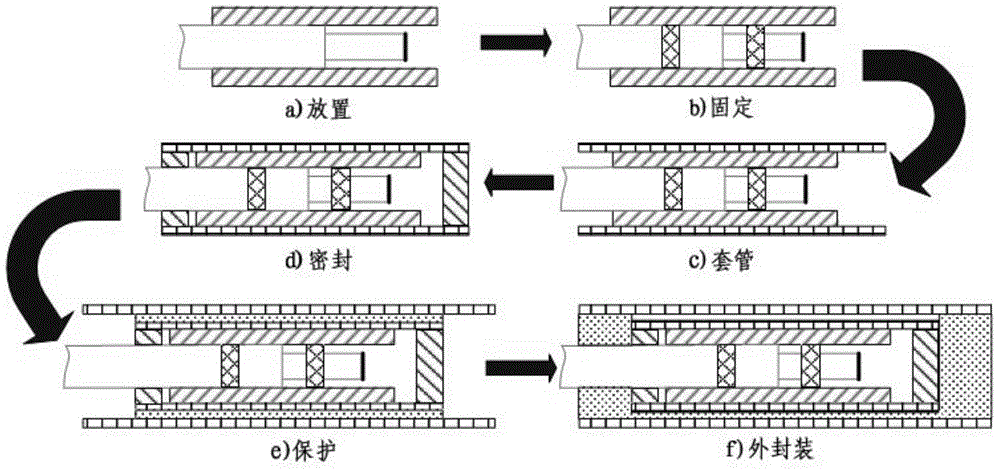

[0027] Process methods such as figure 2 Shown: The optical fiber end face reflector is set up from left to right at the fiber output end, bare fiber and anti-reflection coating. The length of the bare fiber part is 2-3mm, and the anti-reflection film is coated on the rightmost end of the bare fiber part, including the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com