Separating apparatus and method for liquid hydrogen fluoride solution

A separation device and separation method technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as the inability to separate liquid hydrogen fluoride solution into solid and liquid, reduce the number of transfers, ensure safety and environmental protection, and meet airtightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

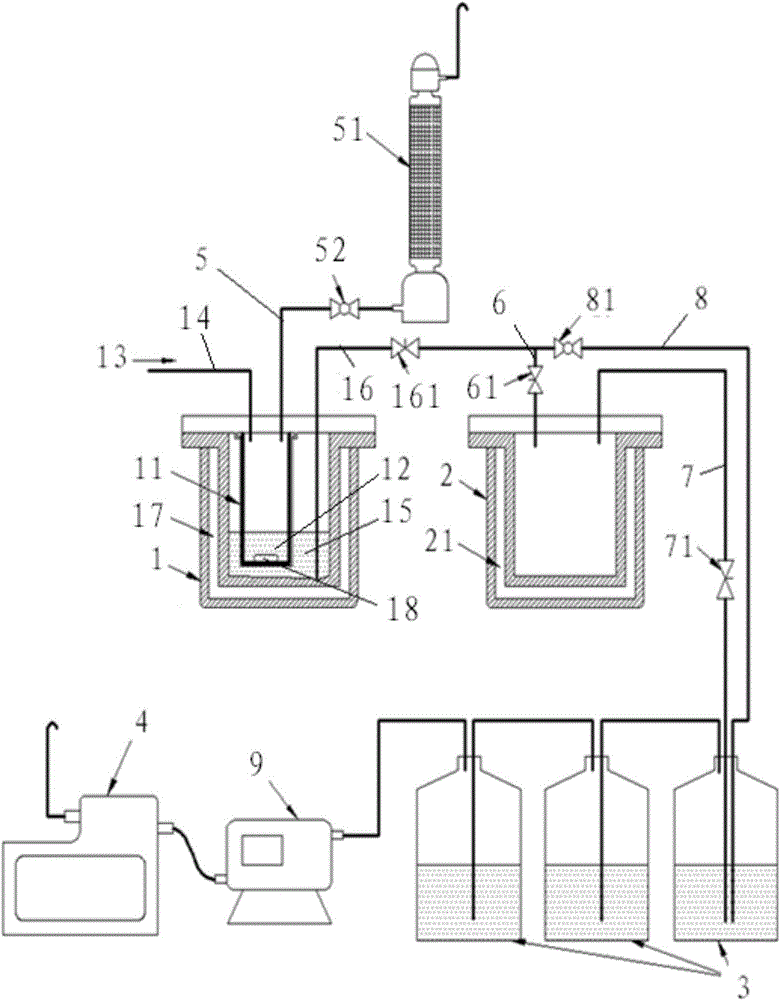

[0023] Such as figure 1 As shown, the separation device for liquid hydrogen fluoride solution according to the present invention includes a jacketed sealed reactor 1 , a jacketed sealed collector 2 , a second absorber 3 and a pump 4 .

[0024] The jacketed sealed reactor 1 is fixed with a filter sleeve 11, the solid solute 12 and PTFE stirrer 18 are accommodated in the filter sleeve 11, and the liquid hydrogen fluoride 13 is introduced into the filter sleeve through the liquid inlet pipe 14 11 and under the action of the PTFE stirrer 18, the solid solute 12 is dissolved to form a liquid hydrogen fluoride solution 15, and the liquid hydrogen fluoride solution 15 passes through the filter membrane sleeve 11 and is exported through the outlet pipe 16. In addition, the jacketed sealed reactor 1 communicates with the atmosphere through the first pipeli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com