Paint mist treating system for paint room

A treatment system and paint room technology, which is applied in the field of production tail gas treatment, can solve the problems of large workshop area, huge processing equipment, secondary pollution, etc., achieve small occupation of work area, high paint mist treatment efficiency, and avoid secondary pollution pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

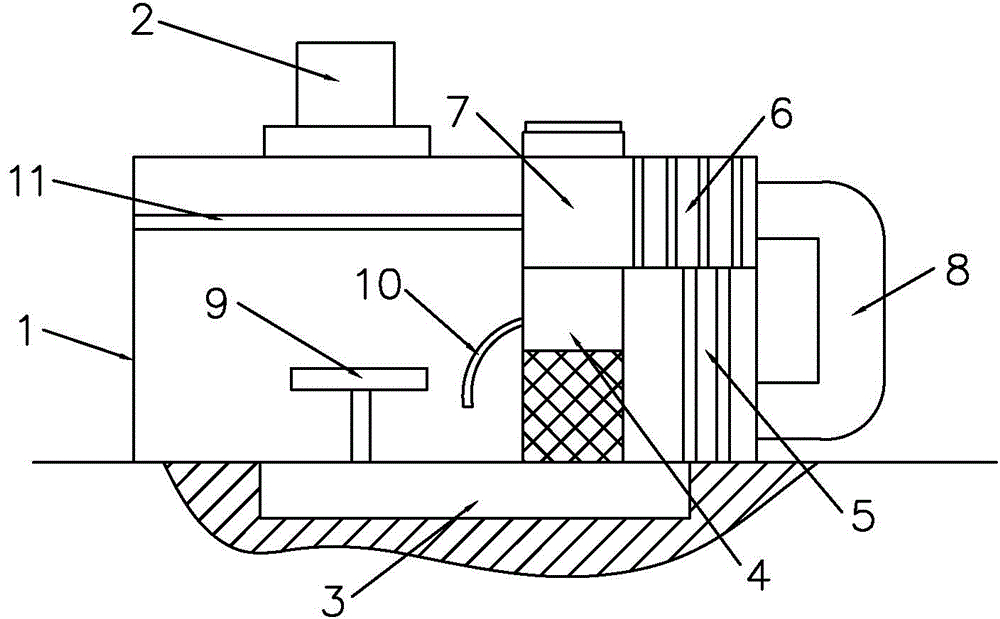

[0016] Such as figure 1 As shown, the present invention provides a paint spray booth paint mist treatment system, including a paint spray booth 1, a paint mist treatment assembly and a paint mist washing pool 3, the paint spray booth 1 is a sealed box, and the upper end of the paint spray booth 1 is provided with a fan 2, The fan 2 is an axial flow fan to ensure a continuous supply of large air volume; there is a filter layer 11 in the paint spraying room 1, which divides the paint spraying room 1 into upper and lower spaces, and the upper space communicates with the fan 2, and the filter layer 11 can filter Dust particles in the wind blown by fan 2; a workbench 9 is installed in the lower space, and a water curtain wall 10 is also installed on the inner wall of the lower space, and the water curtain wall 10 is located above the paint mist was...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap