Restoration method of chromium-polluted soil

A chromium-contaminated soil and process technology, applied in the restoration of contaminated soil, etc., to achieve the effect of no secondary pollution, high economic benefits, and efficient restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

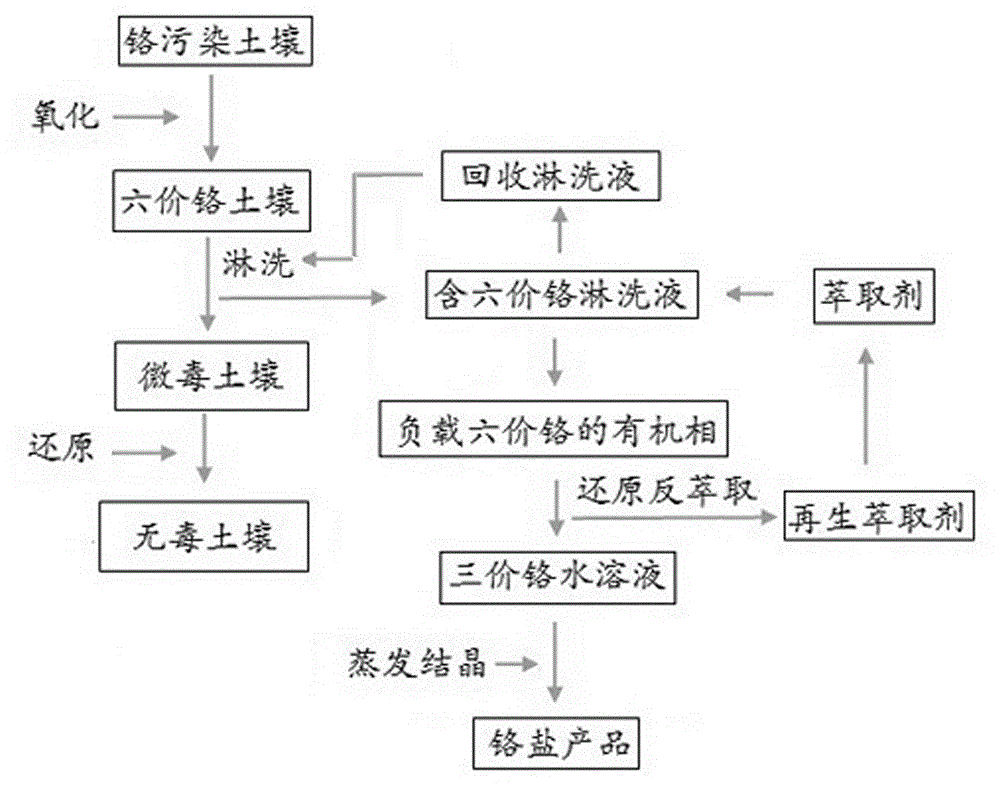

[0039] Embodiment: This embodiment provides a kind of remediation process of chromium-contaminated soil, and the technological process is as follows figure 1 As shown, the specific steps are as follows:

[0040] (1) In this embodiment, the total chromium content in the chromium-contaminated soil of a certain chromium salt factory is 25000-30000 mg / kg. pH=10.0~10.5. The chromium-contaminated soil was crushed, sieved, and piled up to prepare a 2%wt potassium permanganate solution, and adjust the pH value to 4~5 with sulfuric acid. The prepared oxidant solution is sprayed downward from the upper part of the piled soil, and the effluent containing hexavalent chromium flowing out from the lower part of the pile is collected. When the amount of the aqueous solution containing the oxidant reaches 5 times the volume of the soil, stop spraying to obtain hexavalent chromium soil.

[0041] (2) Spray the hexavalent chromium soil with an aqueous solution containing sodium sulfate as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com