Detachable assembling platform and furnace shell welding alignment method

A platform and furnace shell technology, applied in the field of detachable assembly platform and furnace shell welding alignment, can solve the problems of inability to reuse, low welding accuracy, difficult leveling, etc., to increase competitiveness, low installation unit price, and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further describe the detachable assembly platform and furnace shell welding alignment method of the present invention, it will be further described in detail in conjunction with the accompanying drawings.

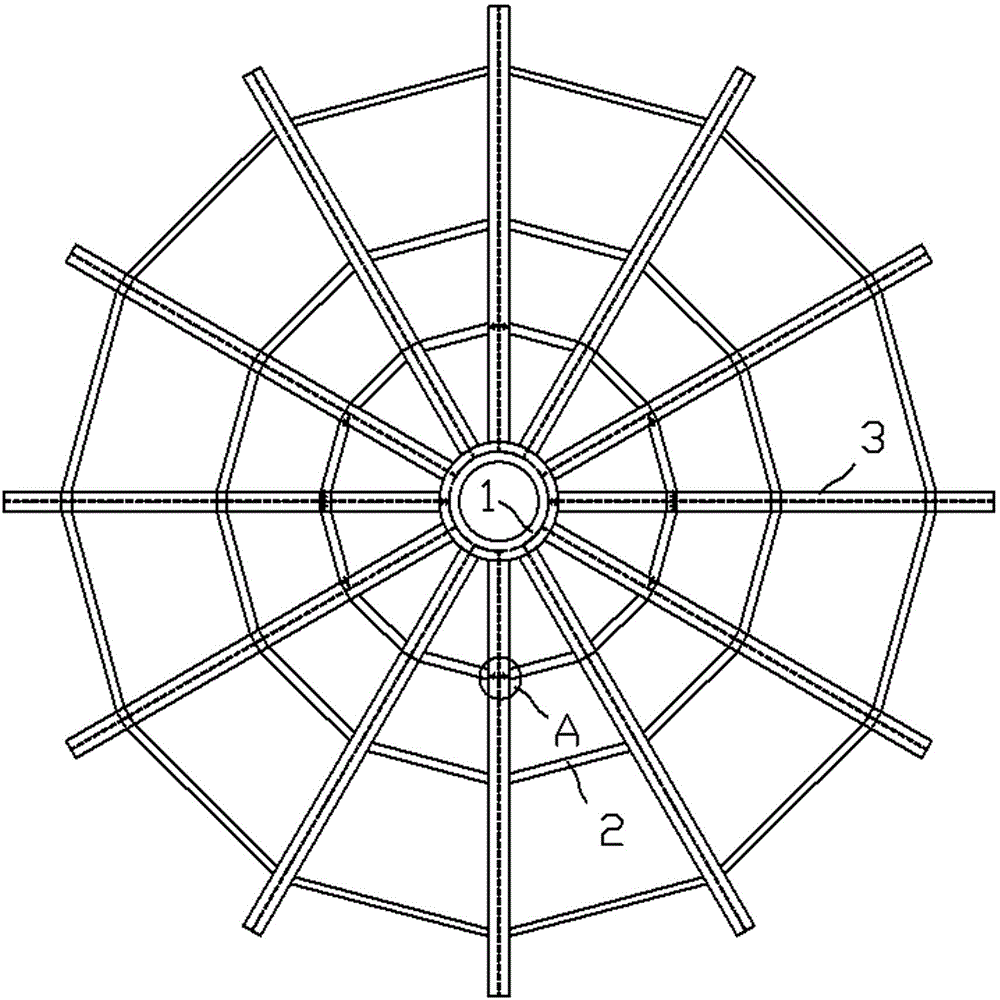

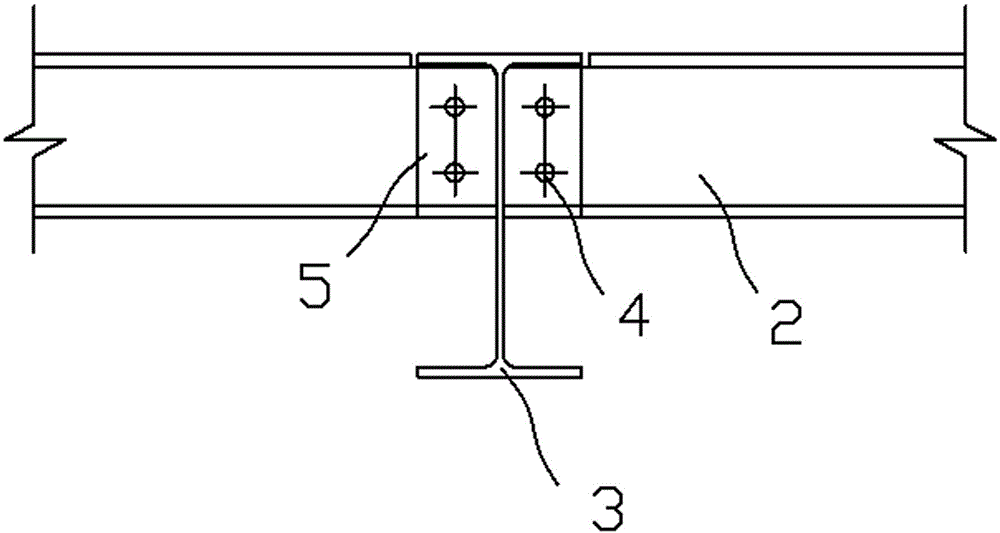

[0019] see figure 1 and 2 , a detachable assembly platform, which is composed of main beam 3, secondary beam 2 and inner circular part 1; there are several main beams 3 arranged in a circular array along the center point of inner circular part 1; between adjacent main beams 3 Connected by several secondary beams 2, the outer side of the inner circular member 1 is formed by the secondary beams 2 to form a circular structure to support the main beam 3 (similar to the shape of a spider web).

[0020] The H-shaped steel web plate of the model H294*200*8*12 is selected for the main beam 3, the I20 steel frame is selected for the secondary beam 2, and the ring-shaped I-beam is selected for the inner circular part 1; the end of the secondary beam 2 extends into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com