Bamboo tube automatic production device and production method

An automatic production and bamboo tube technology, which is applied in mechanical equipment, wood processing equipment, sugarcane machining, etc., can solve the problems of reduced production efficiency, waste of raw materials, and large safety hazards, and achieve the effect of liberating labor and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

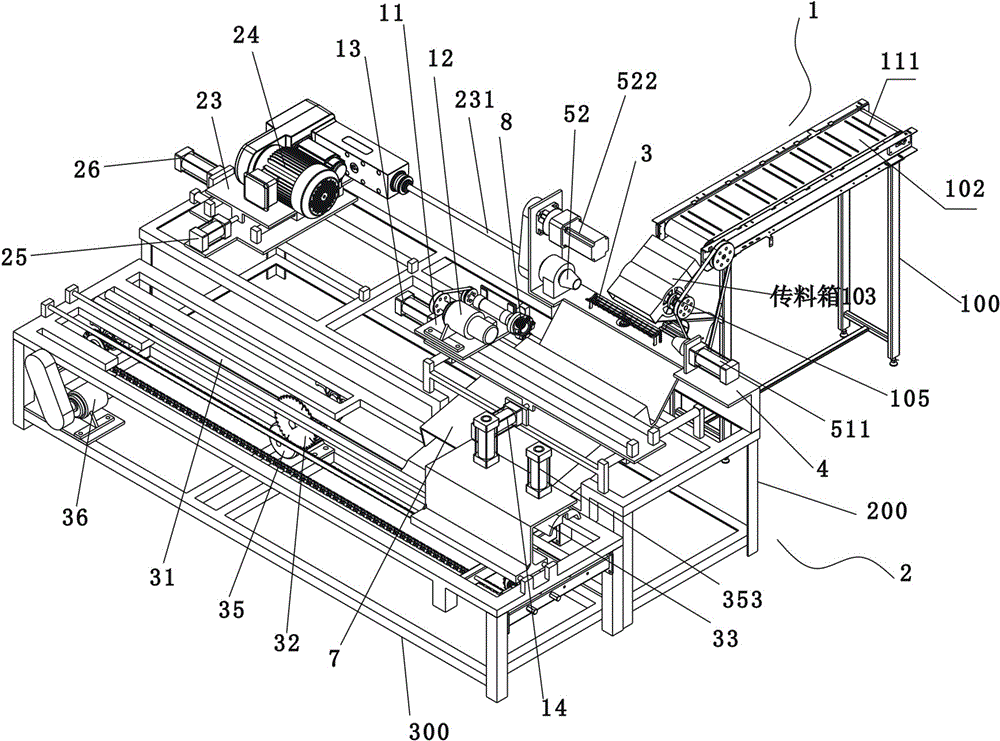

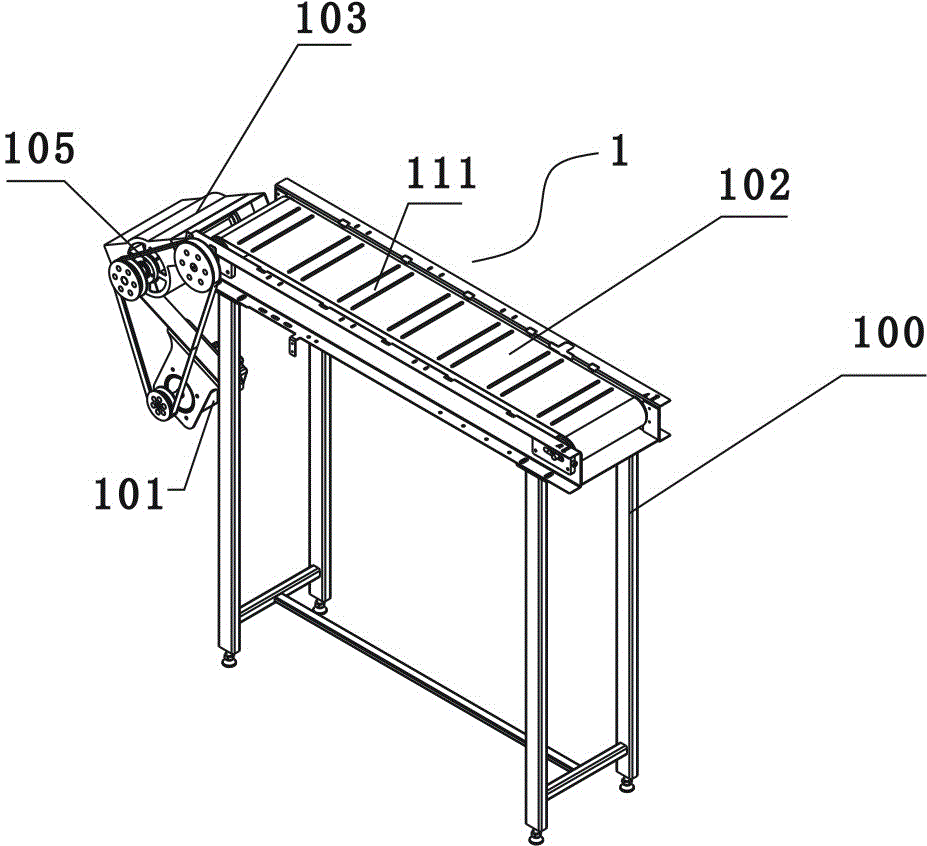

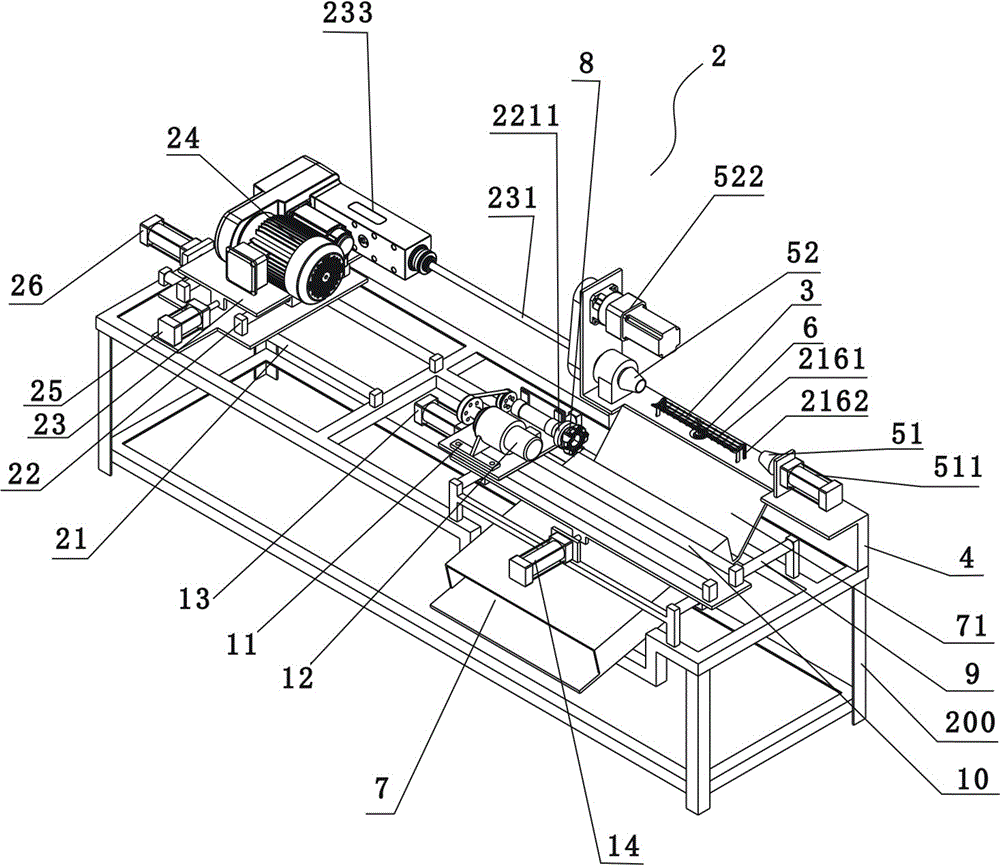

[0027] Below in conjunction with specific embodiment and accompanying drawing ( Figures 1 to 7 ), further elaborating the essence of the present invention.

[0028]A kind of automatic production equipment for bamboo tubes involved in the present invention includes a control system (not shown), a feeding system 1, an impurity removal system 2, and a slotting system. The feeding system 1 includes a first frame 100, and the A transmission device is fixedly connected to the first frame 100, and the transmission device is electrically connected to the control system. The transmission device includes a first controller, a conveyor belt 102, and a transfer box 103. The first controller is The first motor 101, the conveyor belt 102 and the material transfer box 103 are all electrically connected with the first motor 101, and the transmission end of the conveyor belt 102 is provided with a material transfer box 103 for transferring bamboo tubes, the conveyor belt 102 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com