Apparatus used for measuring filling slurry pipeline resistance loss parameter and method thereof

A pipeline resistance and filling slurry technology, which is applied in the direction of measuring devices, fluid dynamics tests, and machine/structural component tests, can solve the problems of long test period, high test cost, and low accuracy, and achieve the goal of data processing The method is simple, the effect of improving the test measurement accuracy and reducing the measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

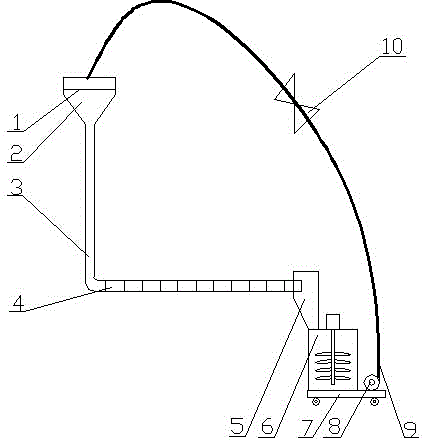

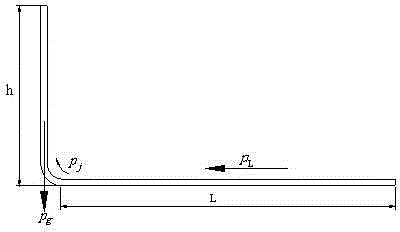

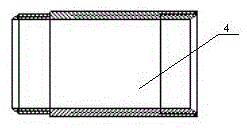

[0032] As shown in the accompanying drawings: a device for measuring the resistance loss parameters of the filling slurry pipeline, including an L-shaped pipe 3, a stirring device 6, a speed-regulating booster pump 8, an electromagnetic flowmeter 10, a mobile support 7, and a stirring device 6 and the speed-regulating pressurized pump 8 are installed and fixed on the mobile support 7, and the stirring device 6 is located below the end of the horizontal section of the L-shaped pipe 3. The horizontal section of the L-shaped pipe 3 is composed of several shorts 4, which is convenient for adjusting the The length of the horizontal section of the tube 3, and by changing the length of the horizontal section of the L-shaped tube 3 to cooperate with the limit line 1, the test operation is simple, and it is suitable for filling materials of various properties; the inner diameter of the L-shaped tube 3 Similarly, the top of the vertical section of the L-shaped pipe 3 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com