An array-type parallel welding device and method for integrated packaged microwave devices

A technology of parallel welding and microwave devices, which is applied in the manufacture of electric solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve the problems of bare chip damage, limited use range and use efficiency, device solder remelting, etc., to reduce labor Strength and operating time, improve seam welding efficiency, and avoid device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

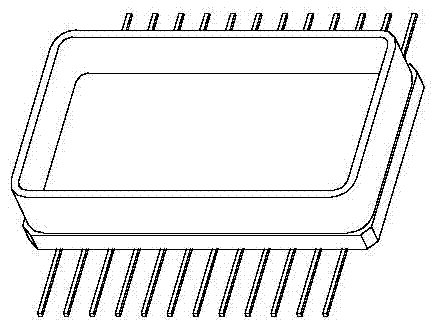

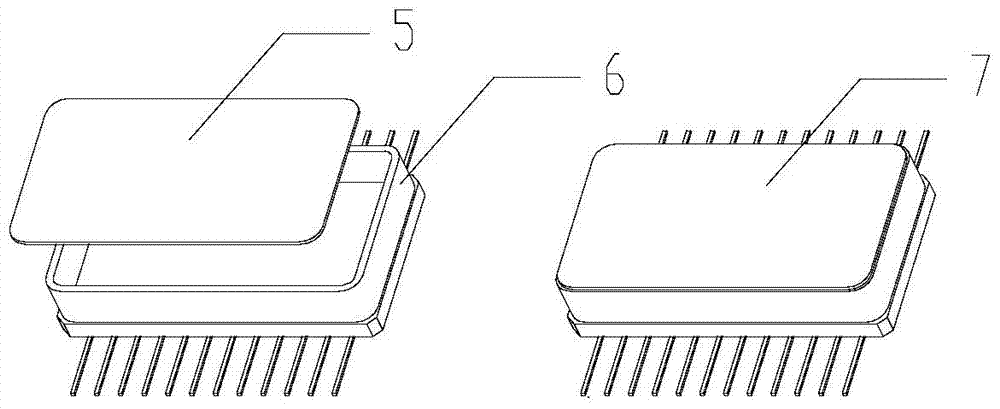

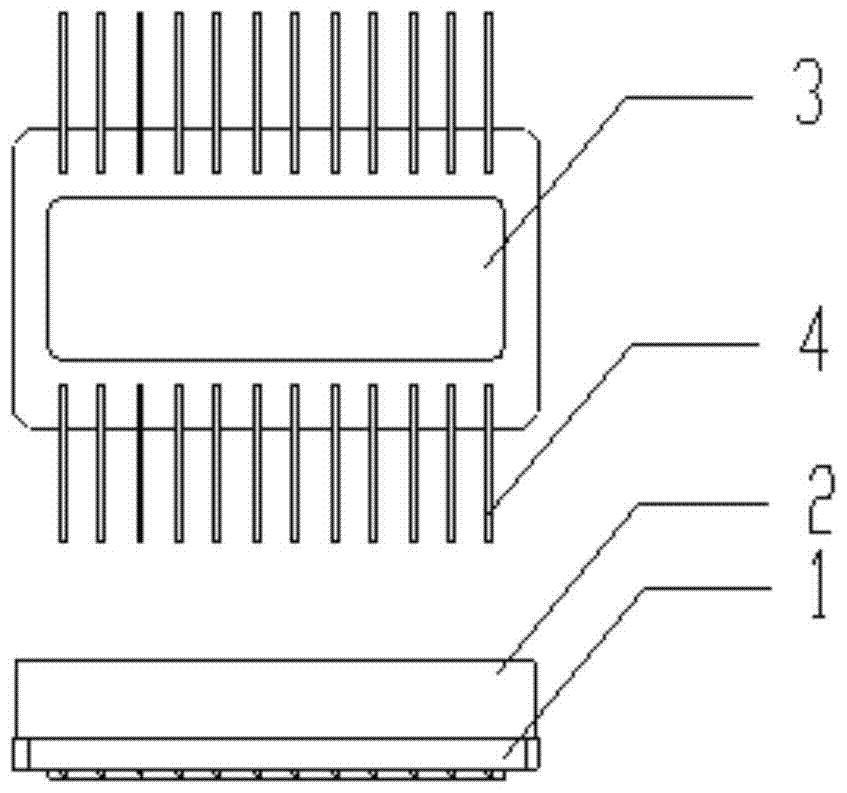

[0034] Such as Figure 1~3 As shown, the housing 6 for integrally packaging microwave devices includes a substrate 1 , a surrounding frame 2 , a bottom plate 3 , and pins 4 . Among them, there is a circuit pattern inside the substrate 1, and a bare chip is installed on the surface, and the electrical interconnection is realized by means of gold wire on the bare chip; The input and output of pin 4 are realized. The surrounding frame 2 and the bottom plate 3 are used to realize the sealing of the bottom and side of the device.

[0035] The casing 6 and the device cover 5 can be tightly connected by means of parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com