Data protection unit heat insulation barrel

A technology of data protection and heat insulation barrel, which is applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of performance discount, insufficient heat insulation barrel technology, stagnation of heat conduction and heat radiation in heat insulation technology, and achieve improved heat insulation effect , the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

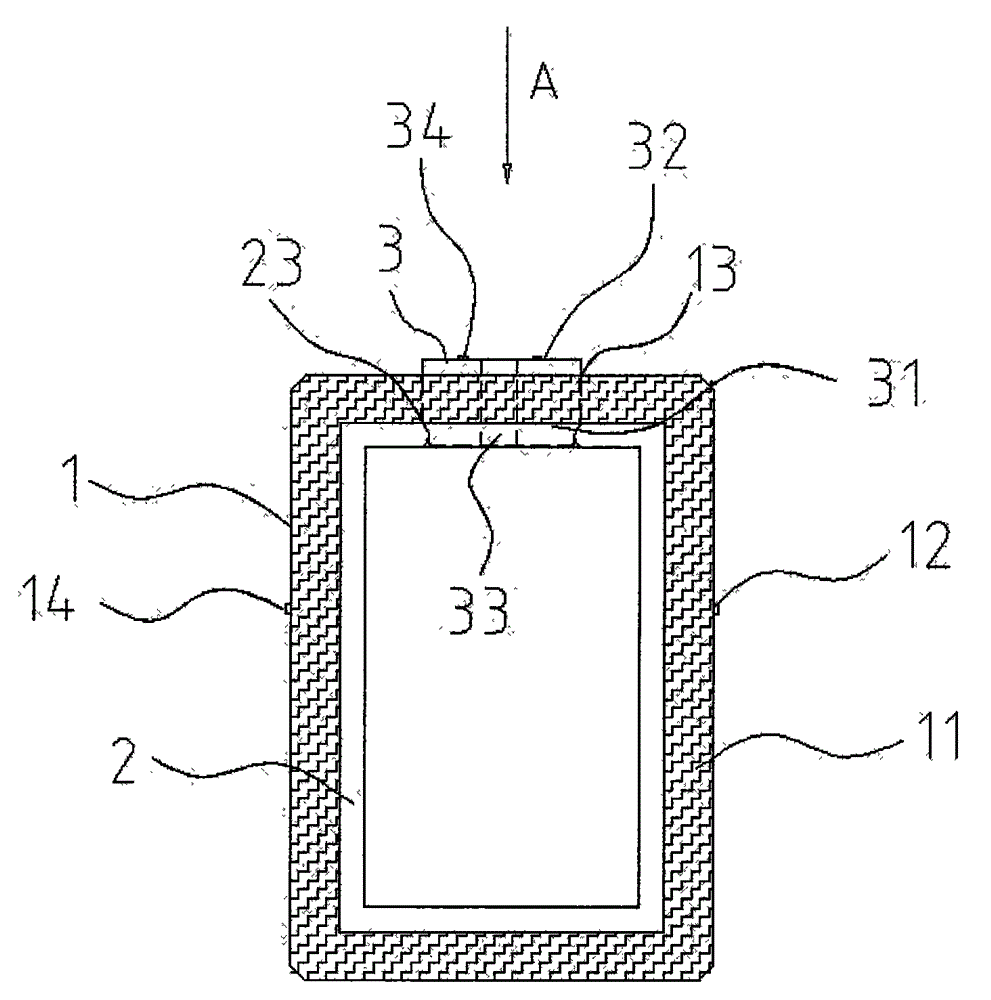

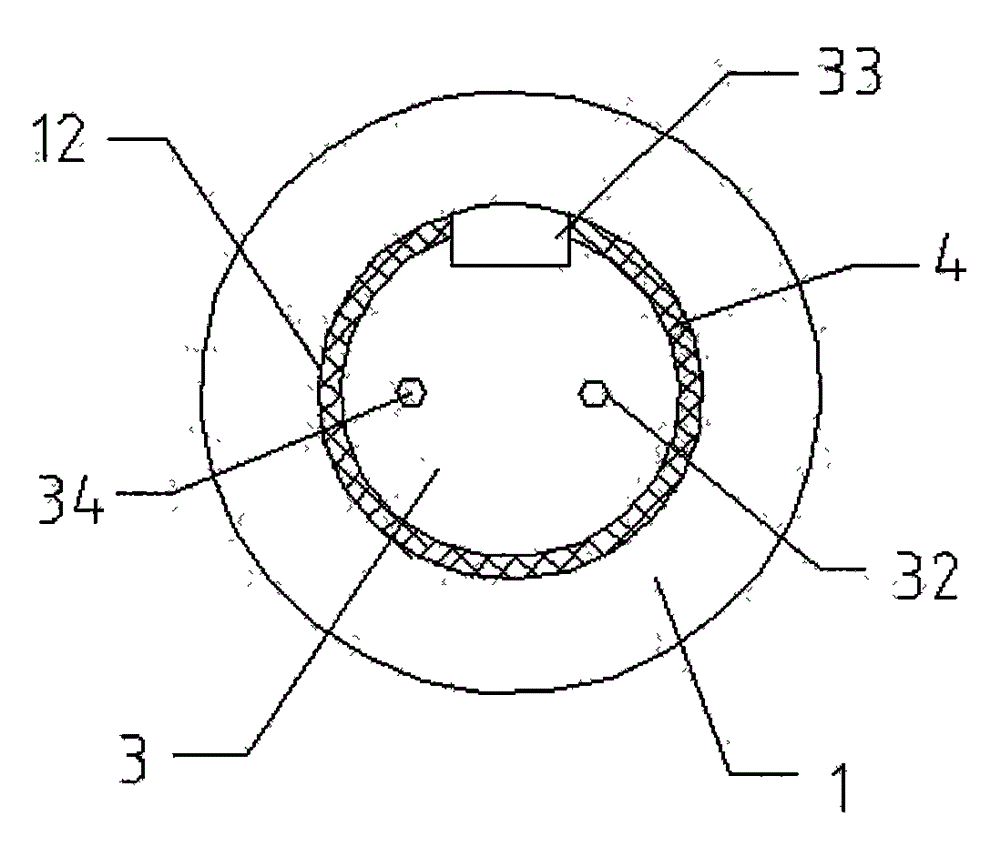

[0015] According to one aspect of the invention, the invention provides a data protection unit heat insulation bucket, such as figure 1 As shown, it includes an outer shell 1, an inner shell of a liquid layer and an upper cover 3 of a thermal insulation bucket. The shell 1 is a cylindrical stainless steel shell, and one end is provided with a first opening 13 corresponding in size and shape to the upper cover 3 of the heat-insulating bucket. The shell 1 is made of 304 stainless steel. The 304 stainless steel has the rust resistance and corrosion resistance suitable for the data unit in the marine environment, and has a certain high temperature resistance, which is conducive to the service life of the marine data unit. The inner shell of the liquid layer is arranged in the outer shell 1 and has a second opening 23 corres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com