Fluorescent-light-source device

A light source device, fluorescent technology, applied in the direction of light source, electric light source, projection device, etc., can solve problems such as failure, high luminous efficiency, and inability to obtain, and achieve the effect of easy formation and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

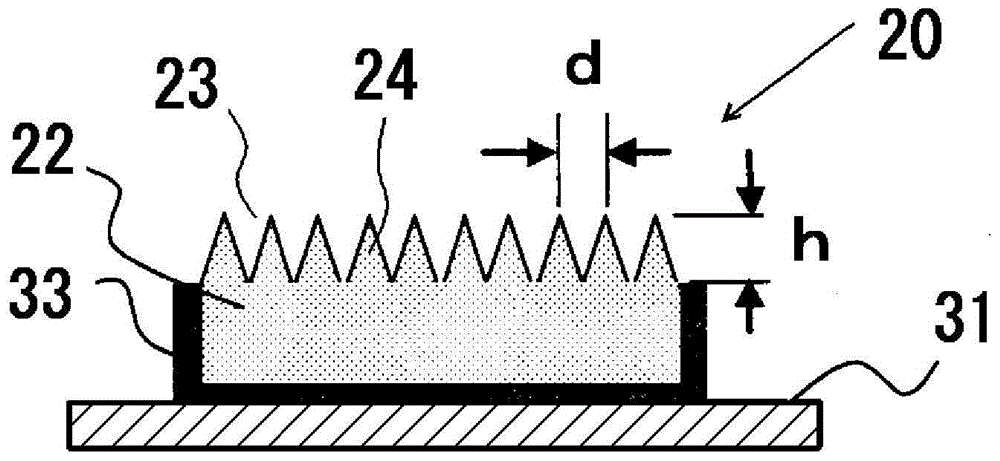

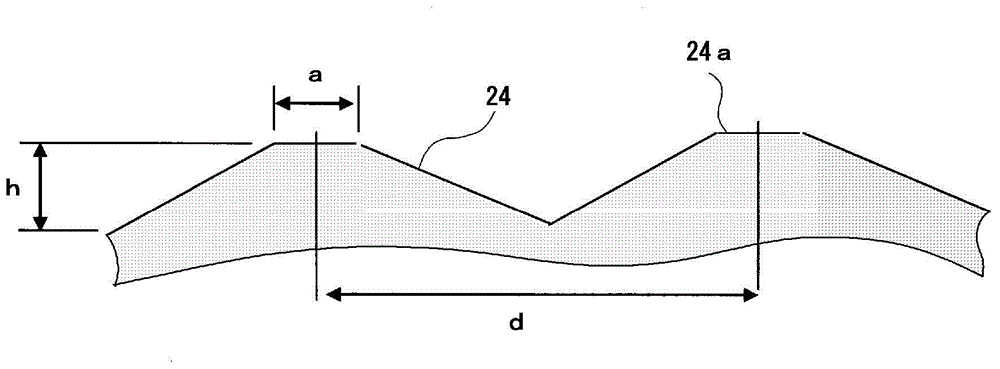

[0105] based on figure 2 With the configuration shown, a plurality of wavelength conversion members having a periodic structure on the surface were fabricated.

[0106] The periodic structures of the manufactured plurality of wavelength conversion members have different aspect ratios. These multiple wavelength conversion members are the following members: adjust the aspect ratio by changing the height (h) of the convex portion (24) in the range of 100 to 1100 nm, each having a conical convex portion (24), a period (d ) is 600 nm and has the following specifications.

[0107] Here, the period (d) is the magnitude of the range in which the diffraction of the fluorescent light emitted from the fluorescent material constituting the fluorescent member (22) occurs.

[0108] [substrate (31)]

[0109] Material: aluminum substrate, size: 25mm (length) x 25mm (width) x 1mm (thickness)

[0110] [fluorescence member (22)]

[0111] Material: LuAG: single crystal of Ce (composition = ...

experiment example 2

[0118] In Experimental Example 1, a fluorescent member with a refractive index of 2.0 was used as the fluorescent member (22) in the wavelength conversion member to make a plurality of wavelength conversion members, and to irradiate the manufactured plurality of wavelength conversion members with light having a peak wavelength of 465 nm as Except for the excitation light, the reflectance of light on the surface of the wavelength conversion member (LD reflectance) and the extraction efficiency of light were measured by the same method as in Experimental Example 1. show the result in Figure 8 . Should Figure 8 In , the measurement result of light reflectance (LD reflectance) is shown by a dotted line, and the measurement result of light extraction efficiency is shown by a solid line.

[0119] As a result, it was confirmed that in the wavelength conversion member, a periodic structure in which approximately tapered convex portions are arranged at a period of the size of the r...

experiment example 3

[0121] In Experimental Example 1, a fluorescent member with a refractive index of 2.3 was used as the fluorescent member (22) in the wavelength conversion member, and a plurality of wavelength conversion members were produced, and the wavelength conversion was measured by the same method as that of Experimental Example 1. Light reflectance (LD reflectance) and light extraction efficiency on the surface of the member. show the result in Figure 9 . Should Figure 9 In , the measurement result of light reflectance (LD reflectance) is shown by a dotted line, and the measurement result of light extraction efficiency is shown by a solid line.

[0122] As a result, it was confirmed that in the wavelength conversion member, a periodic structure in which approximately tapered convex portions are arranged at a period of the size of the range in which the diffraction of the fluorescence emitted from the phosphor constituting the fluorescent member occurs is formed on the excitation li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com