Loofah sponge fiber mattress filling material and preparation method thereof

A technology of loofah fiber and filling material, which is applied in mattresses, fiber processing, spring mattresses, etc., can solve problems such as unfavorable human health, prevent ischemic myocardial damage, overcome large weight and hardness, and improve ventilation Sexual and moisturizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

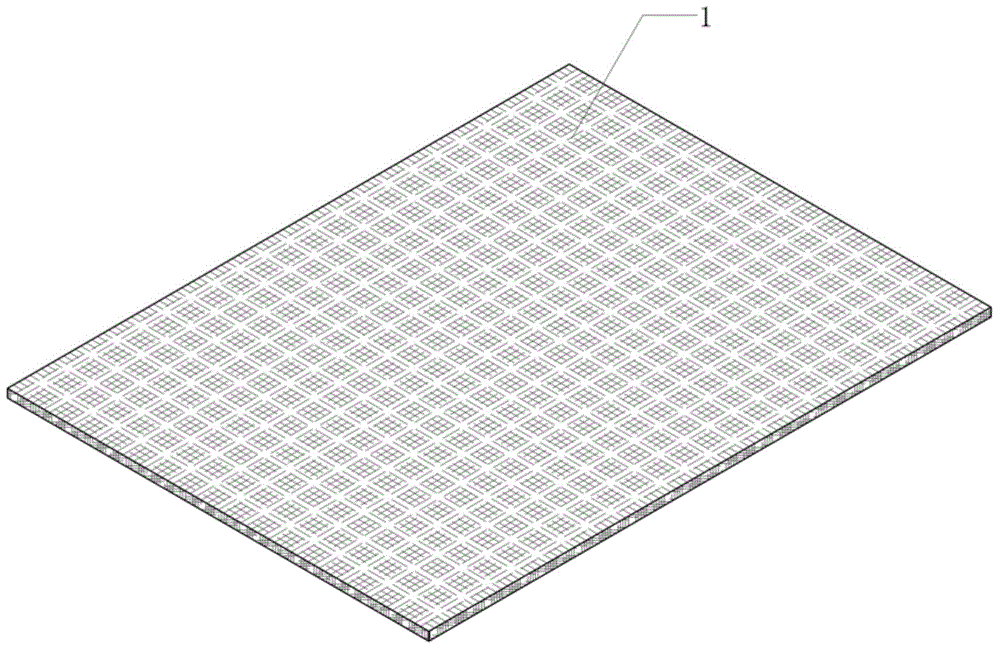

[0050] A loofah fiber mattress filling material, the filling material components include loofah fibers and low-melting short fibers, wherein the mass ratio of the loofah fibers to the low-melting short fibers is 1:0.5-1.2.

Embodiment 2

[0052] A preparation method for loofah fiber mattress filling material, comprising the steps of:

[0053] (1) First, soak the loofah in clear water at room temperature for 1-3 hours, cut open, remove seeds, and wash with boiling water 3 times to remove warm soluble impurities;

[0054] (2) Utilize the cylinder to pierce the carding machine to card, obtain the loofah fiber of length 1cm-5cm;

[0055] (3) drying the loofah fiber, the drying temperature is 100°C-110°C, and the water content is reduced to 7%;

[0056] (4) the loofah fiber processed through step (3) is mixed in a blender with the low-melting short fiber at a mass ratio of 1:0.5-1.2;

[0057] (5) Utilize wind power loosening machine to carry out loosening treatment to the fiber that mixes homogeneously;

[0058] (6) The loose mixed fibers are paved with a fixed grammage using a fiber laying machine, and the grammage range of the pavement is 1500g / m 2 -2800g / m 2 ;

[0059] (7) Hot press the paved mixed fiber at ...

Embodiment 3

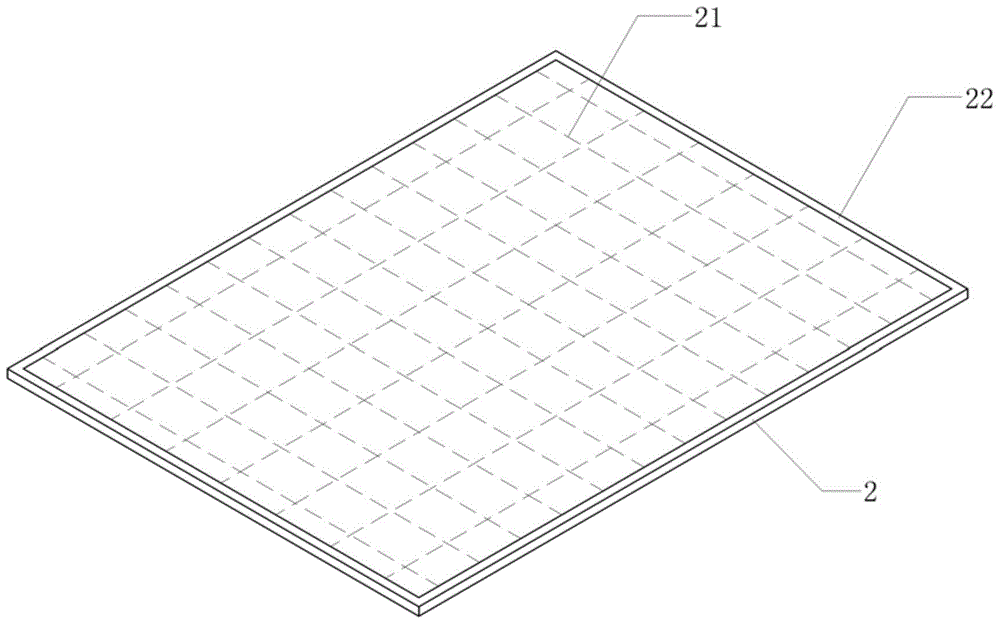

[0064] A kind of preparation method of loofah fiber mattress filling material is characterized in that, comprises the steps:

[0065] (1) Utilize the wind force loosening machine to loosen the loofah fiber;

[0066] (2) Use a net-laying machine to pave the loose loofah fibers with a fixed grammage, and the grammage of the pavement is 500g / m 2 -1500g / m 2 ;

[0067] (3) Add fabric or non-woven fabric to the top and bottom of the paved loofah fiber for quilting, and the quilting distance is 12cm-20cm;

[0068] (4) cutting and trimming the quilted loofah fiber mat material according to the size requirements of the mattress filling material;

[0069] (5) edge banding process, obtain the final loofah fiber mattress filling material two 2, such as figure 2 As shown, 21 is the quilting line on the second loofah fiber mattress pad material, and 22 is the seaming edge of the second loofah fiber mattress pad material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Average linear density | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com