Plant fiber mattress

A plant fiber and mattress technology, applied in the field of mattresses, can solve the problems of latex mattresses, sponge mattresses with poor air permeability and moisture dissipation, limited natural latex collagen materials, and prone to mildew, so as to prevent ischemic myocardium Effects on injury, improvement of rest efficiency, and healthy sleep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

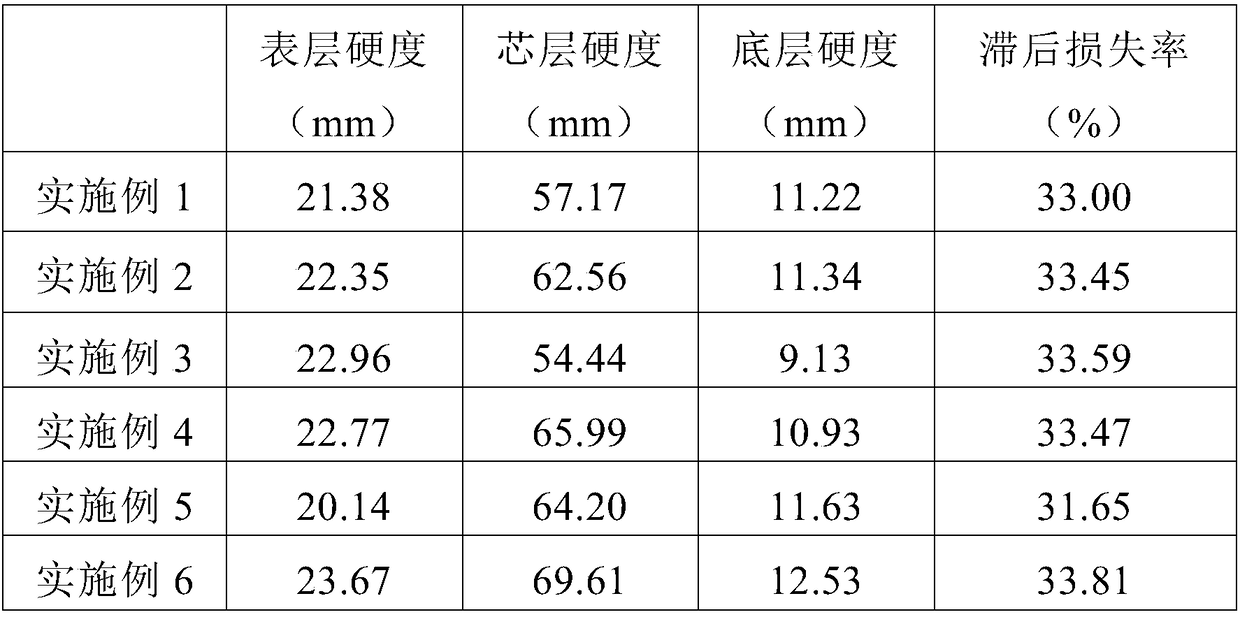

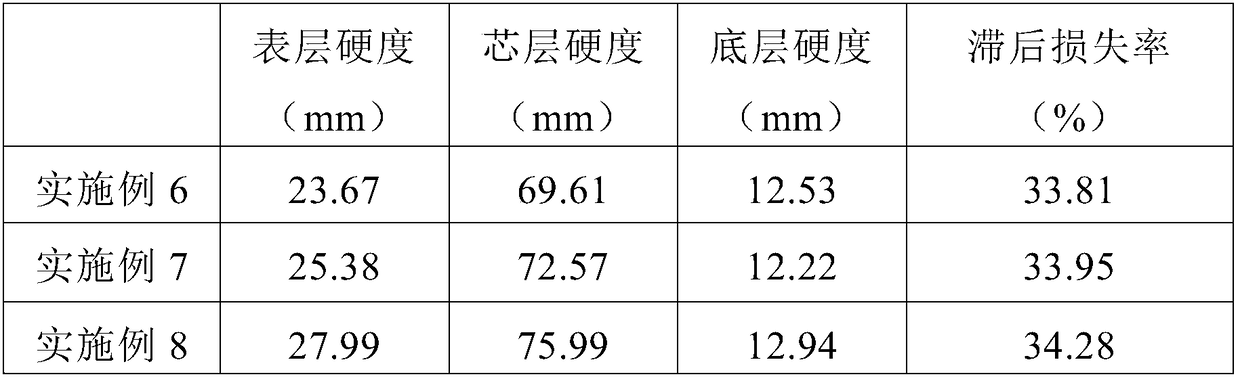

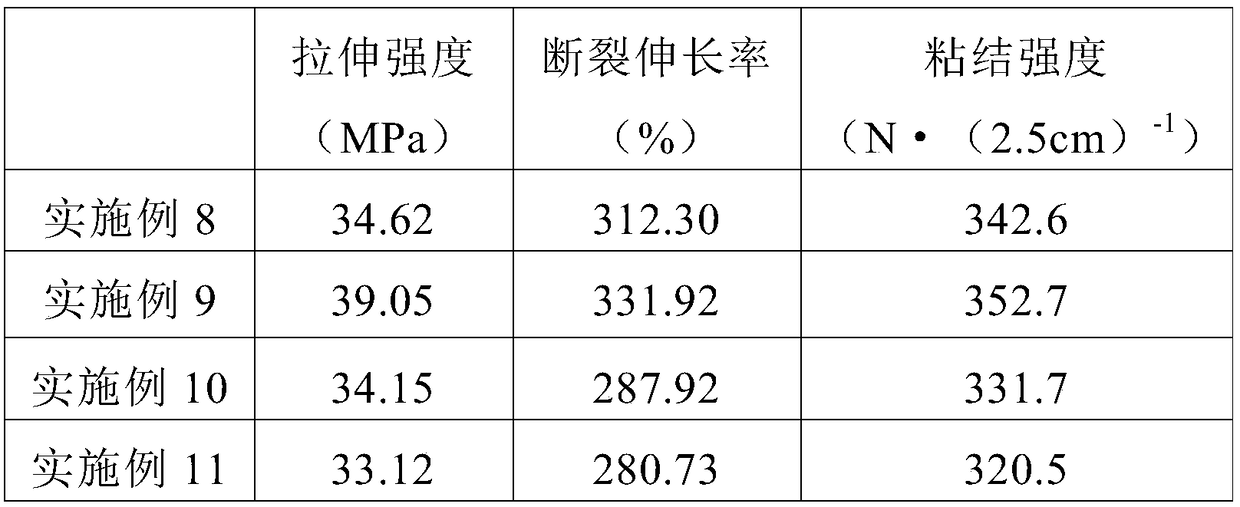

Embodiment 1

[0051] The mattress comprises, from top to bottom, a fabric layer, an upper bedding layer, a loofah core layer, a lower bedding layer and a fabric layer.

[0052] The material of the fabric layer is 80% cotton and 20% polyester, and the thickness of the fabric layer is 5mm.

[0053] The thickness of described upper bedding layer is 100mm, is arranged successively from top to bottom latex layer, sponge layer, horsehair layer, and the thickness of latex layer is 30mm, and the thickness of sponge layer is 40mm, and the thickness of horsehair layer is 30mm.

[0054] The preparation method of the loofah core layer is as follows: peel the dried loofah fruit, rinse it with flowing water, drain it, and air-dry it in the air until the water content is 3wt%, to obtain the loofah; then put the loofah at 40°C Dry for 2 hours, cut into a cylinder with a height of 60mm; compress the cylinder into a unit with a height of 30mm in a hot press; arrange the units according to the size of the mat...

Embodiment 2

[0057] The mattress comprises, from top to bottom, a fabric layer, an upper bedding layer, a loofah core layer, a lower bedding layer and a fabric layer.

[0058] The material of the fabric layer is 80% cotton and 20% polyester, and the thickness of the fabric layer is 5mm.

[0059] The thickness of described upper bedding layer is 100mm, is arranged successively from top to bottom latex layer, horsehair layer, sponge layer, and the thickness of latex layer is 30mm, and the thickness of sponge layer is 40mm, and the thickness of horsehair layer is 30mm.

[0060] The preparation method of the loofah core layer is as follows: peel the dried loofah fruit, rinse it with flowing water, drain it, and air-dry it in the air until the water content is 3wt%, to obtain the loofah; then put the loofah at 40°C Dry for 2 hours, cut into a cylinder with a height of 60mm; compress the cylinder into a unit with a height of 30mm in a hot press; arrange the units according to the size of the mat...

Embodiment 3

[0063] The mattress comprises, from top to bottom, a fabric layer, an upper bedding layer, a loofah core layer, a lower bedding layer and a fabric layer.

[0064] The material of the fabric layer is 80% cotton and 20% polyester, and the thickness of the fabric layer is 5mm.

[0065] The thickness of described upper bedding layer is 100mm, is arranged successively from top to bottom as horse hair layer, latex layer, sponge layer, and the thickness of latex layer is 30mm, and the thickness of sponge layer is 40mm, and the thickness of horse hair layer is 30mm.

[0066] The preparation method of the loofah core layer is as follows: peel the dried loofah fruit, rinse it with flowing water, drain it, and air-dry it in the air until the water content is 3wt%, to obtain the loofah; then put the loofah at 40°C Dry for 2 hours, cut into a cylinder with a height of 60mm; compress the cylinder into a unit with a height of 30mm in a hot press; arrange the units according to the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com