Preparation method of C18 reverse phase silica gel bonded stationary phase

A technology of stationary phase and reverse silica gel, applied in the field of preparation of high performance liquid chromatography packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

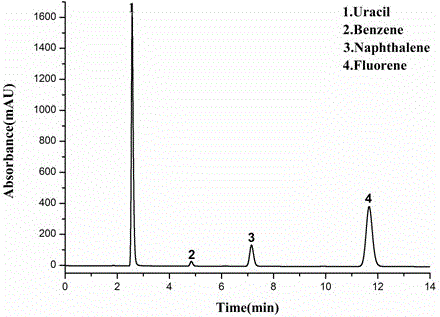

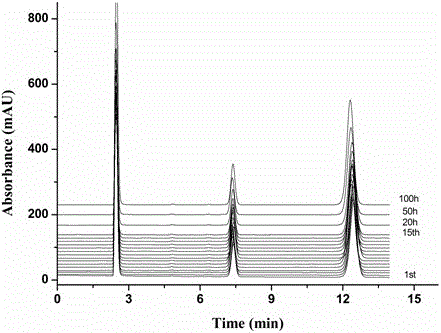

Embodiment 1

[0015] (1) Add 50 g of unactivated silica gel and 300 mL of concentrated hydrochloric acid into a 500 mL beaker, stir occasionally, let stand for 24 h, filter, then wash repeatedly with deionized water until the filtrate is neutral, vacuum at 120°C (-0.9 MPa) and dried overnight; (2) Weigh (1) 5 g of pretreated spherical porous silica gel (SPS, particle size 10 μ, pore size 10 nm) into a three-neck flask, add 50 mL of dry toluene, and stir magnetically to make the silica gel Suspended in the solution, then added 2.5 mL of octadecyltrichlorosilane and 1 mL of dried triethylamine, passed through dry nitrogen, and refluxed at 105°C for 24 h. Stop the reaction, filter the product, and wash it thoroughly with dry toluene, toluene, methanol, absolute ethanol and acetone in turn, and dry it under vacuum (-0.9 MPa) at 80°C overnight; (3) Take the product obtained in (2) in a three-necked flask, Add 50 mL of dry toluene, stir magnetically to suspend the silica gel in the solution, then...

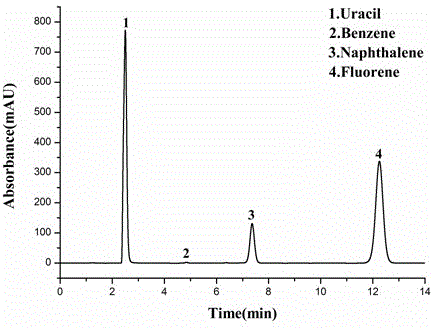

Embodiment 2

[0017] (1) Add 50 g of unactivated silica gel and 300 mL of concentrated hydrochloric acid into a 500 mL beaker, stir occasionally, let stand for 24 h, filter, then wash repeatedly with deionized water until the filtrate is neutral, vacuum at 120°C (-0.9 MPa) and dried overnight; (2) Weigh (1) 10 g of pretreated spherical porous silica gel (SPS, particle size 10 μ, pore size 10 nm) into a three-necked flask, add 100 mL of dry toluene, and stir magnetically to make the silica gel Suspended in the solution, then added 5 mL of octadecyltrichlorosilane and 2 mL of dried triethylamine, passed through dry nitrogen, and refluxed at 105°C for 24 h. Stop the reaction, filter the product, wash thoroughly with dry toluene, toluene, methanol, absolute ethanol and acetone in turn, and dry under vacuum (-0.9 MPa) at 80°C overnight. (2) Take the product obtained in (1) in a three-necked flask, add 100 mL of dry toluene, stir magnetically to suspend the silica gel in the solution, then add 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com