OTS self-assembling water inhibition quartz sand as well as preparation method and application thereof

A technology of quartz sand and self-assembly, which is applied in the field of proppant for sand control and fracturing in oil and gas fields. The effect of good oil performance, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

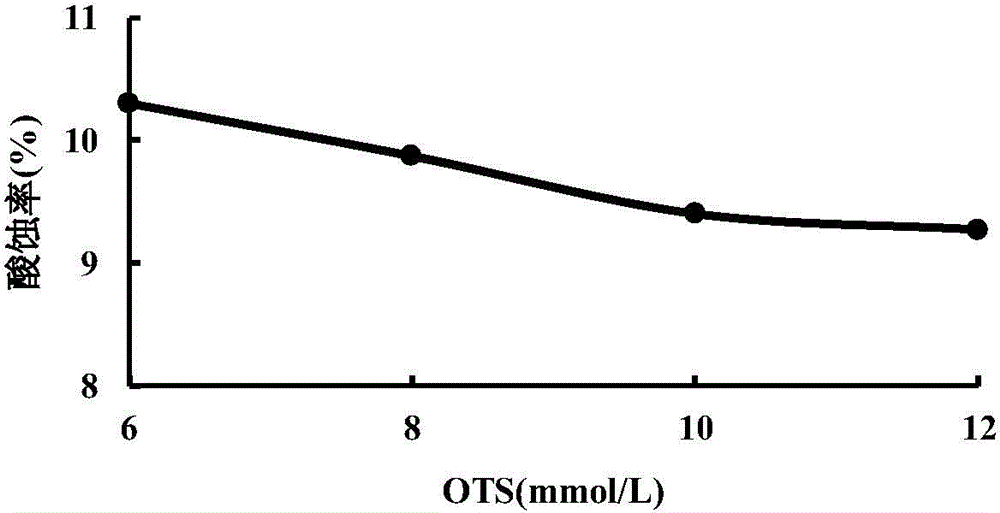

[0045] A preparation method of OTS self-assembled water-suppressing quartz sand, the steps are as follows:

[0046] (1) Measure 100mL of toluene, add it to a beaker, then add 0.233g of octadecyltrichlorosilane (OTS) and stir until uniform to obtain a reaction in which the concentration of octadecyltrichlorosilane (OTS) is 6mmol / L liquid;

[0047] (2) Take 300g of quartz sand, wash it with distilled water for 2 times, dry it, soak it in chromic acid lotion with a concentration of 12wt% for 0.5h, wash it with distilled water for 2 times, and dry it to obtain the treated quartz sand;

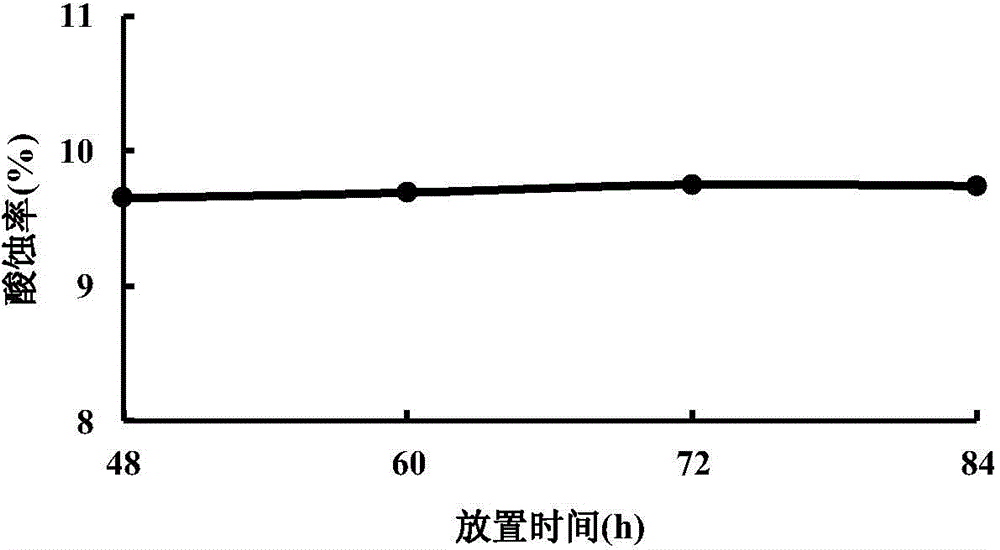

[0048] (3) Place the treated quartz sand obtained in step (2) in the reaction solution obtained in step (1), soak and react for 0.5h, filter, take the precipitate, and then use toluene, acetone, absolute ethanol Rinse with distilled water respectively, and place in the air for 48 hours to dry to obtain OTS self-assembled water-suppressing quartz sand.

Embodiment 2

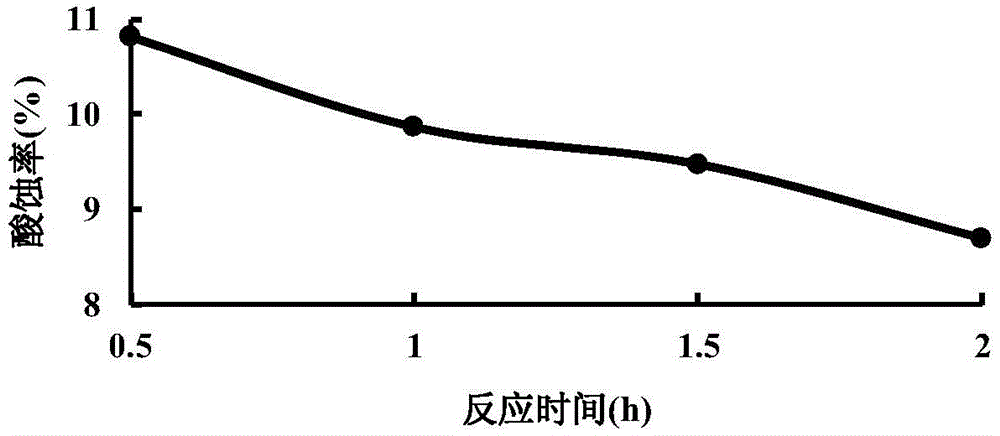

[0050] A preparation method of OTS self-assembled water-suppressing quartz sand, the steps are as follows:

[0051] (1) Measure 100mL of toluene, add it to a beaker, then add 0.233g of octadecyltrichlorosilane (OTS) and stir until uniform to obtain a reaction in which the concentration of octadecyltrichlorosilane (OTS) is 6mmol / L liquid;

[0052] (2) Take 300g of quartz sand, wash it with distilled water for 2 times, dry it, soak it in chromic acid lotion with a concentration of 12wt% for 0.5h, wash it with distilled water for 2 times, and dry it to obtain the treated quartz sand;

[0053] (3) Place the processed quartz sand obtained in step (2) in the reaction solution obtained in step (1), soak and react for 1 hour, filter to get the precipitate, and then use toluene, acetone, absolute ethanol and Rinse them with distilled water, and place them in the air for 60 hours to dry to obtain OTS self-assembled water-suppressing quartz sand.

Embodiment 3

[0055] A preparation method of OTS self-assembled water-suppressing quartz sand, the steps are as follows:

[0056] (1) Measure 100mL of toluene, add it to a beaker, then add 0.233g of octadecyltrichlorosilane (OTS) and stir until uniform to obtain a reaction in which the concentration of octadecyltrichlorosilane (OTS) is 6mmol / L liquid;

[0057] (2) Take 300g of quartz sand, wash it with distilled water for 2 times, dry it, soak it in chromic acid lotion with a concentration of 12wt% for 0.5h, wash it with distilled water for 2 times, and dry it to obtain the treated quartz sand;

[0058] (3) Place the treated quartz sand obtained in step (2) in the reaction solution obtained in step (1), soak and react for 1.5 hours, filter to get the precipitate, and then use toluene, acetone, absolute ethanol Rinse with distilled water respectively, and place in the air for 72 hours to dry to obtain OTS self-assembled water-suppressing quartz sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com