Ultrasonic vibration assisted magnetic grinding device

A technology of ultrasonic vibration and magnetic force, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problem that the transducer amplitude is small and cannot meet the needs of grinding, and achieve the change of uniformity , The device is suitable for a wide range, good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

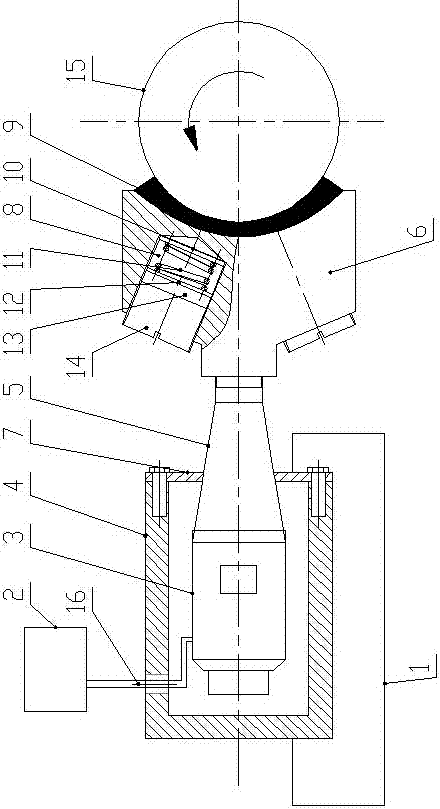

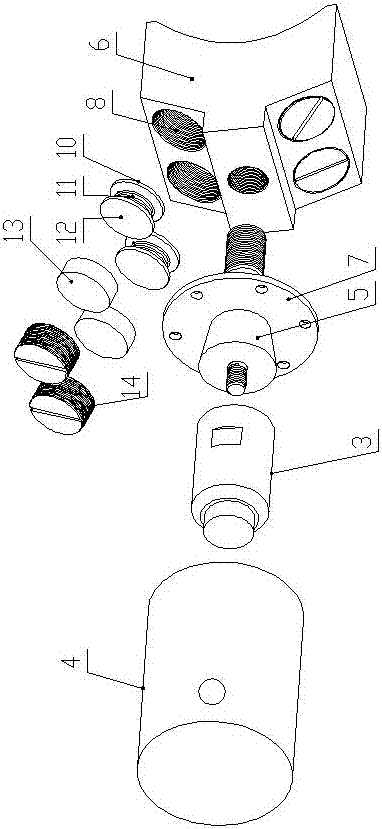

[0020] Such as figure 1 and figure 2 As shown, the ultrasonic vibration assisted magnetic grinding device of the present invention includes a fixed base 1, an ultrasonic generator 2, a transducer 3, a protective sleeve 4, a cone-cylindrical composite horn 5, a magnetic field intensity adjustment mechanism, The tool head 6 and the magnetic abrasive material 9, the protective sleeve 4 are arranged on the fixed base 1, the transducer 3 is horizontally arranged in the protective sleeve 4, the ultrasonic generator 2 passes through the cable 16 of the protective sleeve 4 and the transducer 3 connection, the power output end of the transducer 3 is connected to the larger end of the horn 5, the front end of the protective sleeve 4 is provided with a flange 7, and the smaller end of the horn 5 passes through the flange 7 horizontally forward , the tool head 6 rear end is connected with the smaller head of the horn 5, the working end of the tool head 6 front side is an arc surface str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com