A kind of production technology of environment-friendly high-toughness duralumin alloy profile

A technology of aluminum alloy profiles and hard aluminum alloys, which is applied in the production process of environmentally friendly and high-toughness hard aluminum alloy profiles, to achieve excellent toughness and tensile strength, production process and cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A production method of an environmentally friendly high-toughness hard aluminum alloy profile:

[0028] (1) Ingredients and smelting:

[0029] Ingredients according to mass percentage: Cu 5.3%, Fe 3.2%, Mn 0.2%, Mg 2.5%, Zn 1.5%, Si 0.5%, Ni 0.1%, Ti 0.2%, the rest is Al, at a temperature of 780℃~ Melting at 800°C for 8 hours to obtain molten aluminum alloy;

[0030] (2) Horizontal continuous casting:

[0031] The obtained aluminum alloy solution is subjected to horizontal continuous casting at a temperature of 725° C., and cleaned;

[0032] (3) Continuous extrusion:

[0033] The extrusion speed is 5r / min, and the rounded corner of the mold entrance is r=0.4mm to obtain a semi-finished aluminum alloy profile;

[0034] (4) Three-stage aging heat treatment:

[0035] Carry out three-stage aging heat treatment to the semi-finished aluminum alloy profile obtained in step (3), specifically:

[0036] Level 1: The temperature is 300°C, the time is 2 hours, and then the al...

Embodiment 2

[0040] A production method of an environmentally friendly high-toughness hard aluminum alloy profile:

[0041] (1) Ingredients and smelting:

[0042] Ingredients according to mass percentage: Cu 5%, Fe 2%, Mn 0.1%, Mg 1.5%, Zn 1.5%, Si 1%, Ni 0.1%, Ti 0.2%, the rest is Al, at a temperature of 780 ° C ~ Melting at 800°C for 6 hours to obtain molten aluminum alloy;

[0043] (2) Horizontal continuous casting:

[0044] The obtained aluminum alloy solution is subjected to horizontal continuous casting at a temperature of 780° C., and cleaned;

[0045] (3) Continuous extrusion:

[0046] The extrusion speed is 3r / min, and the rounded corner of the mold entrance is r=0.7mm to obtain semi-finished aluminum alloy profiles;

[0047] (4) Three-stage aging heat treatment:

[0048] Carry out three-stage aging heat treatment to the semi-finished aluminum alloy profile obtained in step (3), specifically:

[0049] Level 1: The temperature is 200°C, the time is 5 hours, and then the alumi...

Embodiment 3

[0053] A production method of an environmentally friendly high-toughness hard aluminum alloy profile:

[0054] (1) Ingredients and smelting:

[0055] Ingredients according to mass percentage: Cu 5.5%, Fe 4.5%, Mn 0.1%, Mg 0.5%, Zn 0.8%, Si 0.7%, Ni 0.1%, Ti 0.2%, the rest is Al, at a temperature of 780℃~ Melting at 800°C for 7 hours to obtain molten aluminum alloy;

[0056] (2) Horizontal continuous casting:

[0057] The obtained aluminum alloy solution is subjected to horizontal continuous casting at a temperature of 740° C., and cleaned;

[0058] (3) Continuous extrusion:

[0059] The extrusion speed is 4r / min, and the rounded corner of the mold entrance is r=0.6mm to obtain semi-finished aluminum alloy profiles;

[0060] (4) Three-stage aging heat treatment:

[0061] Carry out three-stage aging heat treatment to the semi-finished aluminum alloy profile obtained in step (3), specifically:

[0062] Level 1: The temperature is 250°C, the time is 4 hours, and then the alu...

PUM

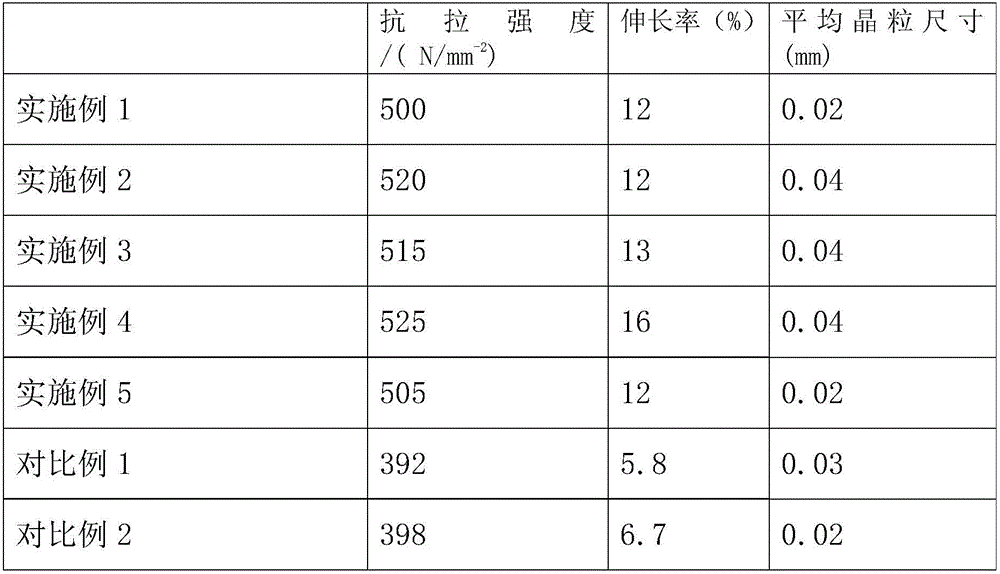

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com