Vane carrier for compressor or turbine section of axial turbo machine

A compressor, carrier technology, applied in parts of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problems of time-consuming, expensive manufacturing of multi-layer components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

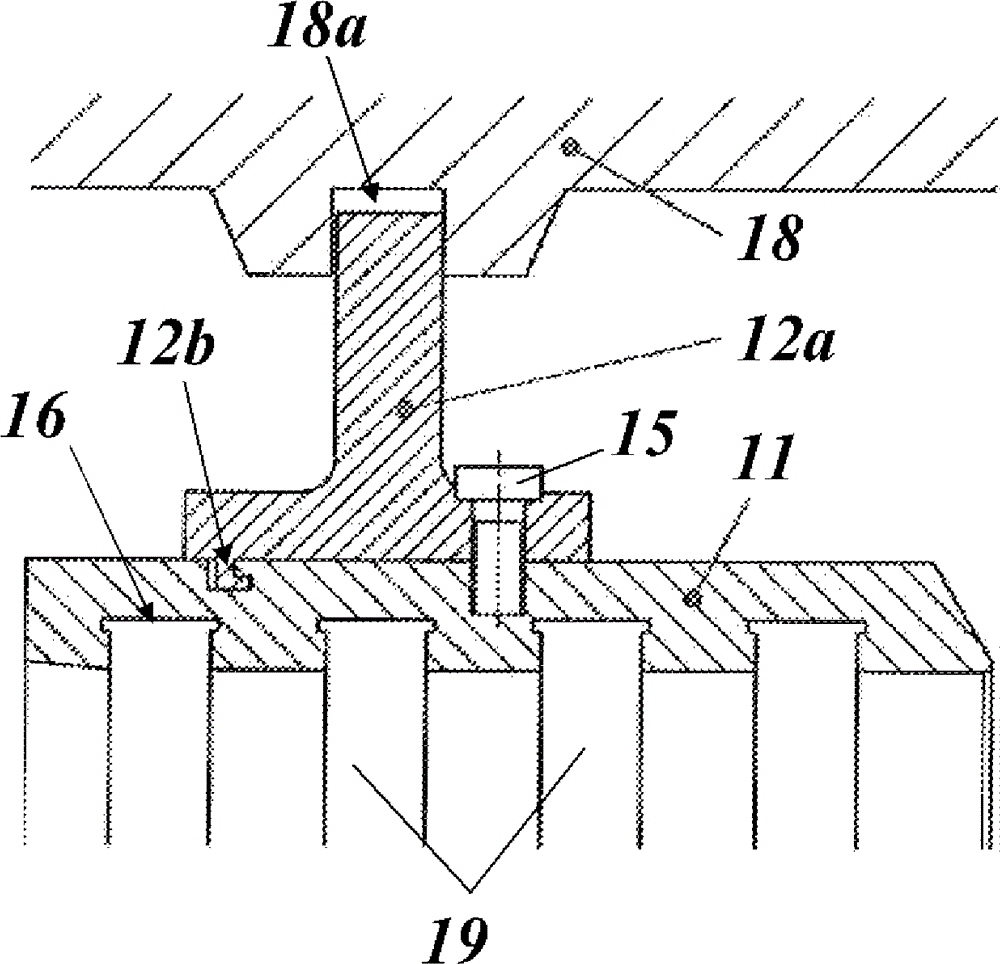

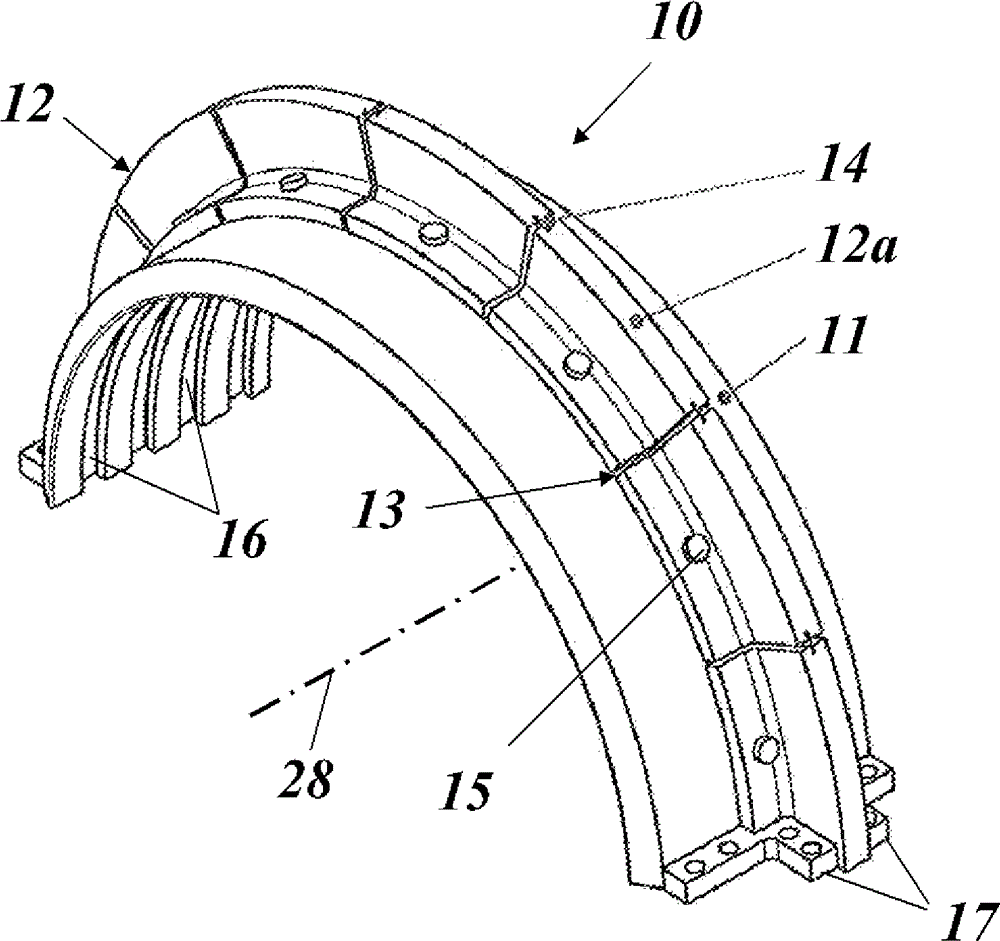

[0048] Low thermal expansion (low CTE) materials bring significant benefits in reduction of compressor clearances. Unfortunately, these materials are only very expensive nickel alloy steel. The hybrid design of the vane carrier according to the invention allows the application of low thermal expansion materials for the main cylindrical portion of the carrier, while the less critical support and sealing structures are formed from standard inexpensive steel.

[0049] Both design proposals have the same rationale of using low thermal expansion material for the cylindrical section and standard low alloy steel for the support section of the vane carrier.

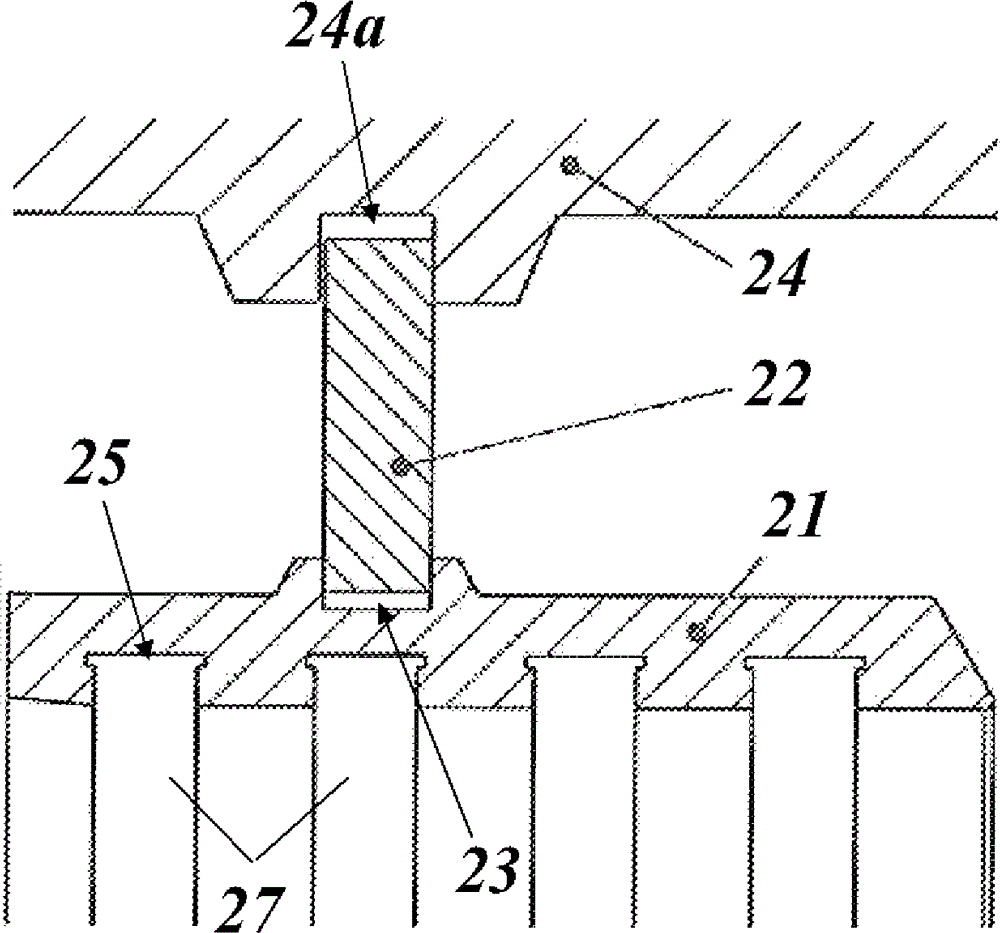

[0050] In both designs, as in figure 1 and figure 2 (first design) and image 3 and Figure 4 As shown in (the second design), the respective cylindrical portions 11 and 21 of the vane carriers 10 and 20 are respectively formed of a low thermal expansion material to reduce the operating clearance of the compressor. The purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com