A method for displaying the prior austenite grain boundaries of p91, p92 ferritic heat-resistant steel

A technology of austenitic grain boundaries and heat-resistant steel, which is applied in the preparation of test samples, measuring devices, and material analysis through optical means to achieve good reproducibility, easy etching process, and stable display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Sample: P92 ferritic heat-resistant steel (coarse grain structure)

[0031] (2) Sulfuric acid electrolyte concentration: 5%, sulfuric acid electrolysis voltage 8V, sulfuric acid electrolysis time: 30s;

[0032] (3) Nitric acid electrolyte concentration: 65-68%, nitric acid electrolysis voltage 11V, nitric acid electrolysis time: 8s;

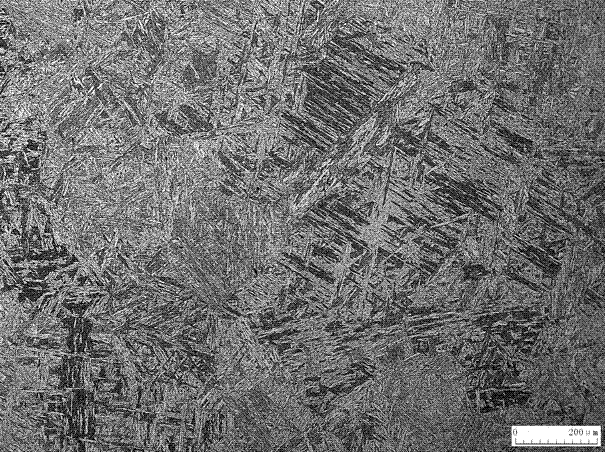

[0033] (4) The complete and clear prior-austenite grain boundaries observed under an optical microscope at a power of 50 times are as follows: image 3 As shown, the measured austenite grain size is 00 grade.

Embodiment 2

[0035] (1) Sample: P92 ferritic heat-resistant steel (coarse grain structure)

[0036] (2) Sulfuric acid electrolyte concentration: 10%, sulfuric acid electrolysis voltage 8V, sulfuric acid electrolysis time: 35s;

[0037] (3) Nitric acid electrolyte concentration: 65-68%, nitric acid electrolysis voltage 10V, nitric acid electrolysis time: 12s;

[0038](4) The complete and clear prior-austenite grain boundaries observed under an optical microscope at a power of 50 times are as follows: Figure 4 As shown, the austenite grain size was determined to be 0.5.

Embodiment 3

[0040] (1) Sample: P92 ferritic heat-resistant steel (fine grain structure)

[0041] (2) Sulfuric acid electrolyte concentration (volume percentage): 15%, sulfuric acid electrolysis voltage 7.5V, sulfuric acid electrolysis time: 40s;

[0042] (3) Nitric acid electrolyte concentration (mass percentage): 60-64%, nitric acid electrolysis voltage 10V, nitric acid electrolysis time: 10s;

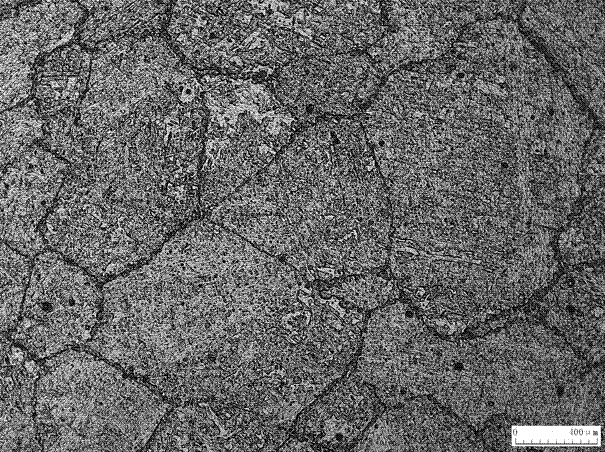

[0043] (4) The complete and clear prior-austenite grain boundary diagram observed under the optical microscope at 100 times is as follows Figure 5 As shown, the austenite grain size was determined to be grade 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com