Cooking fume filter

A filter and oil fume technology, which is applied in the field of textile materials, can solve the problems of low protective performance of the gaseous part and neglect of the filter, and achieve the effect of wide application range, comfortable contact and no irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

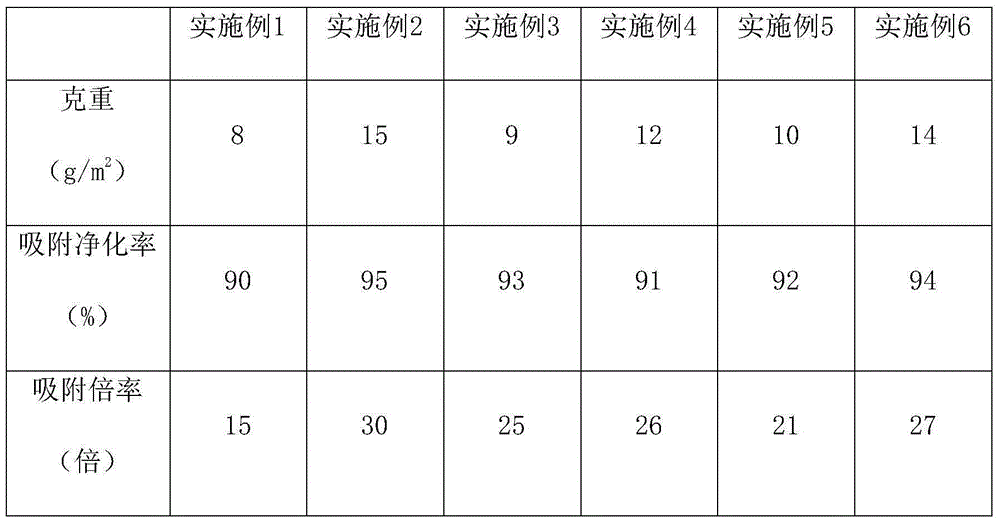

Embodiment 1

[0026] A filter sheet for cooking fume, comprising 5 parts of 70-120nm hydrophobic oil-absorbing shell-shaped polymer oil-absorbing microspheres, 8 parts of nano-sized live ore, and 20 parts of 500-1000nm color-changing oil-absorbing absorbent fibers in parts by weight And 40 parts of medium and high-efficiency non-woven filter cotton.

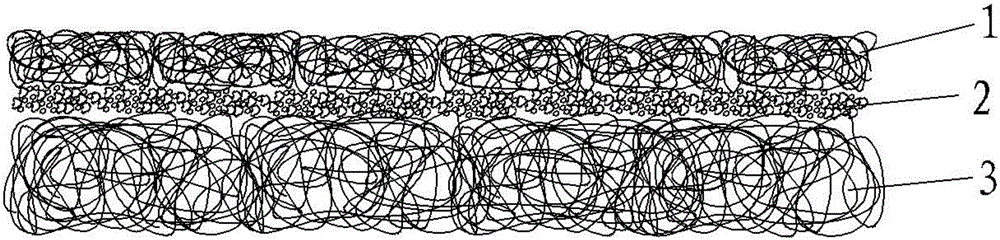

[0027] The filter sheet consists of three layers of high-efficiency adsorption structure, the upper layer is a 1mm color-changing oil-absorbing fiber layer, the middle layer is a composite layer of micro-nano shell-shaped polymer oil-absorbing microspheres and nano-scale live ore, and the lower layer is a 3mm medium-high-efficiency non-woven fabric The filter cotton layer, shell-like polymer oil-absorbing microspheres and nano-active ore are evenly loaded in the middle of the upper and lower carriers. The three-layer high-efficiency adsorption structure is composited by means of ultrasonic wind pressure. The ultrasonic pressure point is a tria...

Embodiment 2

[0029] A filter sheet for cooking fumes, comprising 10 parts of 70-120nm hydrophobic oil-absorbing shell-shaped polymer oil-absorbing microspheres, 12 parts of nano-sized live ore, and 30 parts of 500-1000nm color-changing oil-absorbing absorbent fibers in parts by weight And 60 parts of medium and high-efficiency non-woven filter cotton.

[0030] The filter sheet consists of three layers of high-efficiency adsorption structure, the upper layer is a 2.5mm color-changing oil-absorbing fiber layer, the middle layer is a composite layer of micro-nano shell-shaped polymer oil-absorbing microspheres and nano-sized live ore, and the lower layer is a 5mm medium-high-efficiency non-woven fabric. Cloth filter cotton layer, shell-like polymer oil-absorbing microspheres and nano-active ore are evenly loaded in the middle of the upper and lower carrier. The three-layer high-efficiency adsorption structure is compounded by means of ultrasonic wind pressure. The ultrasonic pressure point is...

Embodiment 3

[0032] A filter for cooking fumes, comprising 8 parts by weight of 70-120nm hydrophobic oil-absorbing shell-shaped polymer oil-absorbing microspheres, 10 parts of nanometer live ore, and 25 parts of 500-1000nm color-changing oil-absorbing fibers And 45 parts of medium and high-efficiency non-woven filter cotton.

[0033] The filter sheet consists of three layers of high-efficiency adsorption structure, the upper layer is a 1.5mm color-changing oil-absorbing fiber layer, the middle layer is a composite layer of micro-nano shell-shaped polymer oil-absorbing microspheres and nano-scale live ore, and the lower layer is a 4mm medium-high-efficiency non-woven fabric. Cloth filter cotton layer, shell-like polymer oil-absorbing microspheres and nano-active ore are evenly loaded in the middle of the upper and lower carrier. The three-layer high-efficiency adsorption structure is compounded by means of ultrasonic wind pressure. The ultrasonic pressure point is a triangle, and the compac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com