Laser scanning method for fabricating three-dimensional objects

A technology of laser scanning and three-dimensional objects, which is applied in the direction of additive manufacturing, processing and manufacturing, and manufacturing tools, can solve the problems of discrete residual stress distribution, affecting scanning efficiency, and large span, so as to improve the quality of workpiece forming, take into account scanning efficiency, and reduce Effect of Residual Stress Influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to allow those skilled in the art to better understand and realize the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

[0033] like figure 1 As shown, the laser scanning method for manufacturing a three-dimensional object includes the following steps:

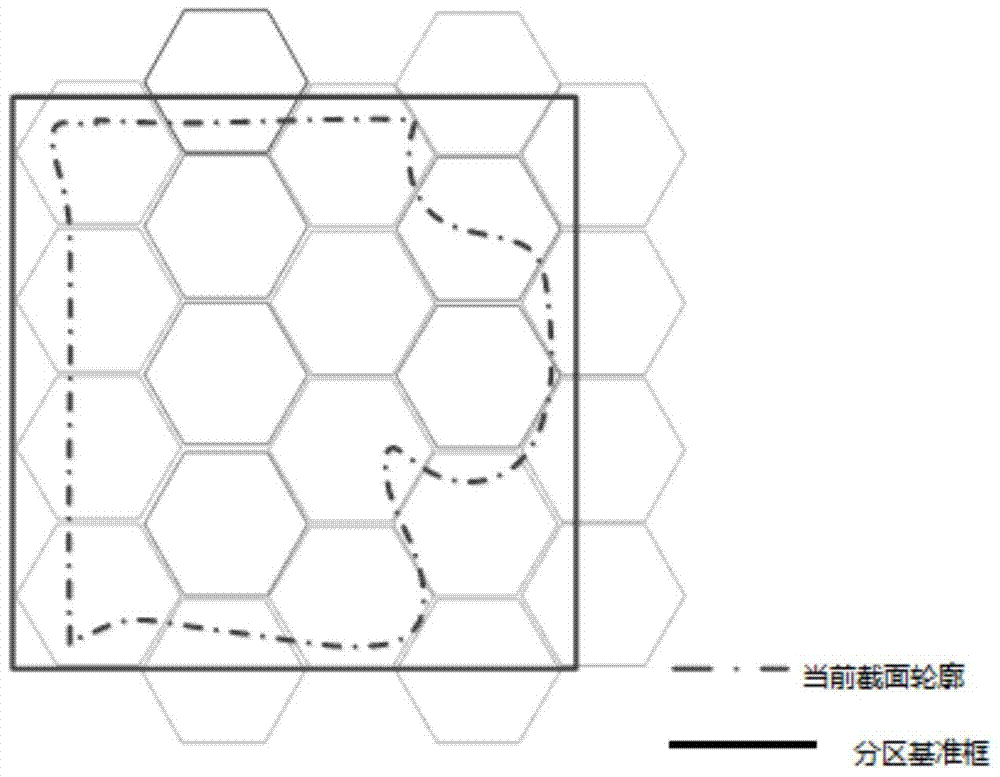

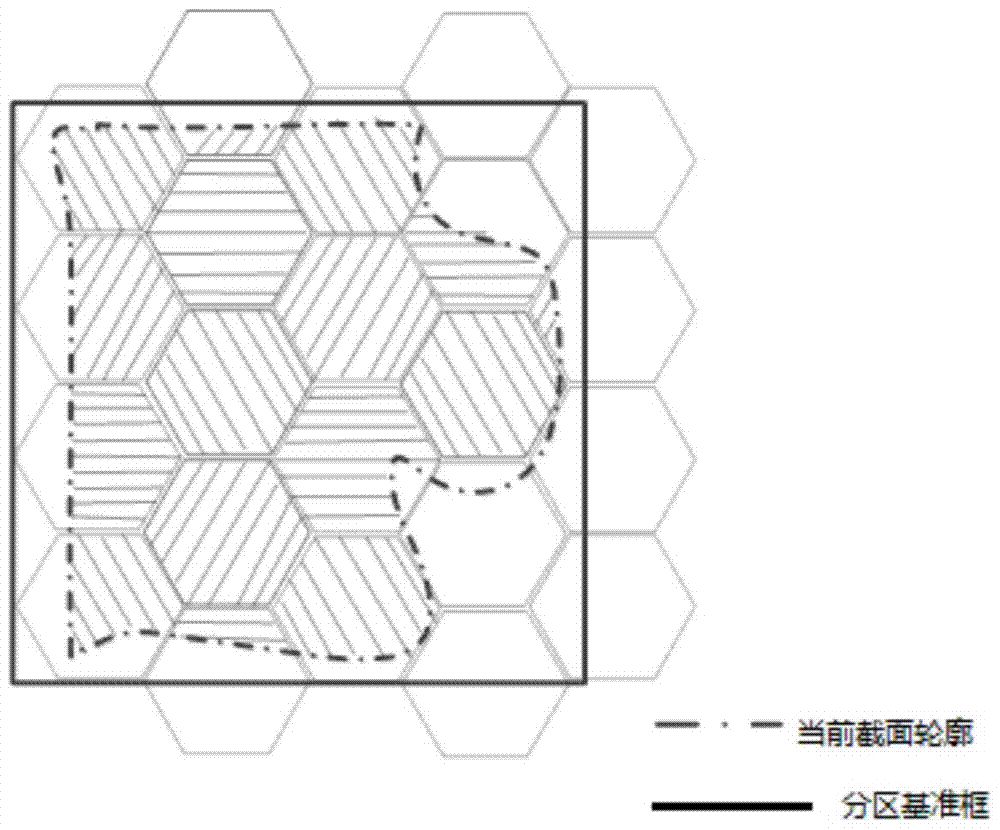

[0034] Step 11: Divide the current cross-sectional profile into several areas to be scanned, and all the boundaries of the current cross-sectional profile are divided, the area to be scanned is a regular hexagon or a local regular hexagon, and the gap between the adjacent areas to be scanned greater than or equal to zero;

[0035] This step 11 can be specifically realized in the following ways, as figure 2 Shown:

[0036] Draw the smallest circumscribed rectangle according to the current section profile;

[0037] Each side of the minimum circumscribed rectangle is expanded by a preset dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com