Full-automatic equipment production line for environment-friendly paper-based pencil processing manufacturing

A processing and manufacturing, fully automatic technology, applied in the direction of non-active pencils, printing, writing utensils, etc., can solve the problems of low production efficiency, time-consuming and labor-intensive processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

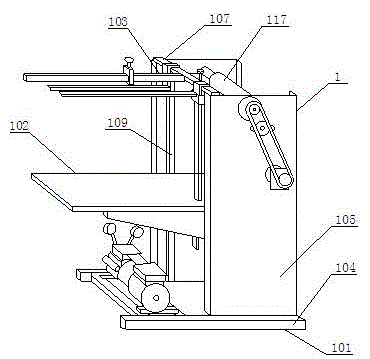

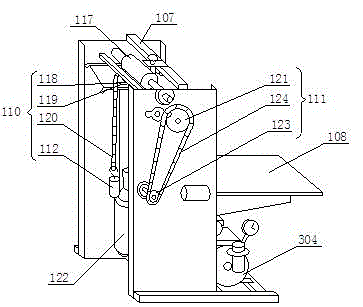

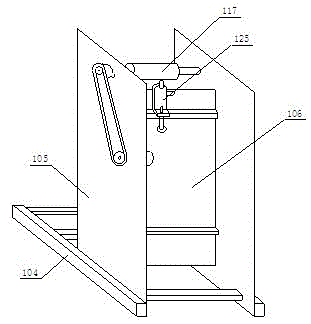

[0080] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

[0081]It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0082] Explanation: The following front side and rear side mean that the forward direction of the conveyed object along the conveying direction of the production line is the front side, and vice versa is the rear side.

[0083] It should be noted that the paper pen refers to a pen formed by using paper material as a pen holder and wrapping a pen core. The invention is mainly applied to the processing of paper pencils, and can be used for processing paper oil pens, ink pens, etc. in other cases, and different paper pens can be formed as long as the refill in the paper pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com