FMEA analysis based comprehensive reliability allocation method for numerical control machine tool

A technology of numerical control machine tools and distribution methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of unreasonable reliability distribution results, insufficient reliability, and affecting the use efficiency and life of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

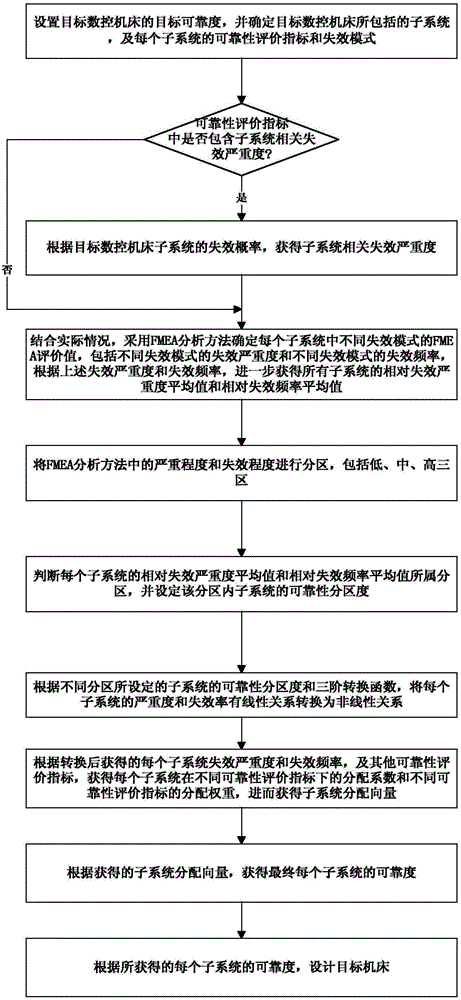

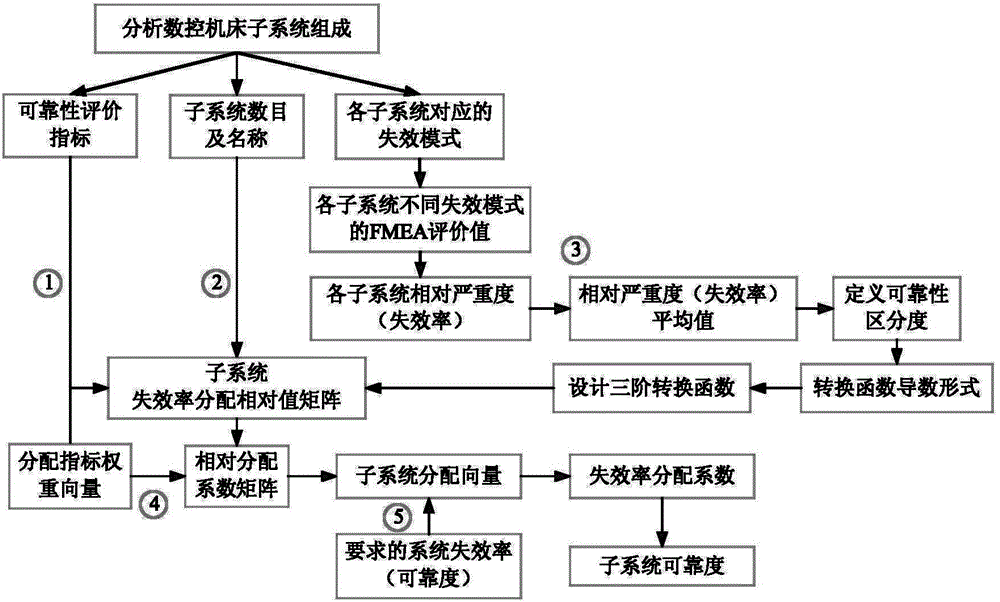

Method used

Image

Examples

Embodiment Construction

[0054] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

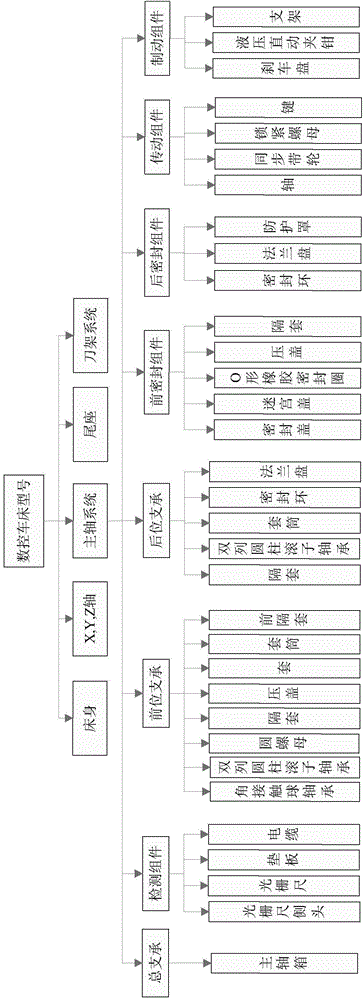

[0055] In the embodiment of the present invention, take the HTC2050i model machine tool as an example, as figure 1 As shown, the main subsystems involved are bed, XYZ axis, spindle system, tailstock, and tool post system; among them, the spindle system can be subdivided into total support, detection components, front support, rear support, and front seal components. , Rear seal assembly, transmission assembly, brake assembly; Among them, the total support includes the spindle box, the detection assembly includes the side head of the grating ruler, the grating ruler, the backing plate, and the cable, and the front support includes angular contact ball bearings and double-row cylindrical rollers. Bearings, round nuts, spacers, glands, sleeves, sleeves, front spacers, rear supports include spacers, double row cylindrical roller bearings, closed rings, fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com