A method of improving DHF corrosion uniformity and controlling corrosion rate

A technology of corrosion rate and uniformity, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increased particles on the surface of silicon wafers, which is not conducive to the uniformity of DHF corrosion, so as to speed up the exchange and improve the uniformity of corrosion , the effect of controllable corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

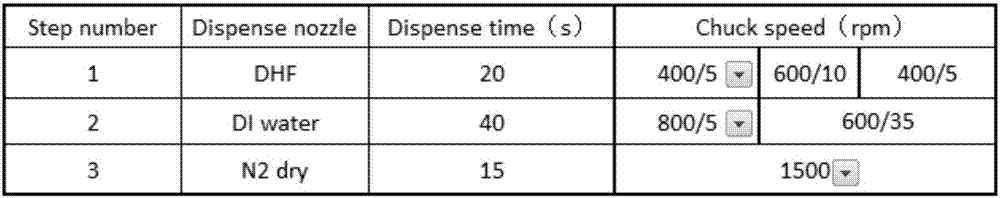

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be further described in detail below.

[0031] In the current silicon wafer DHF cleaning process using a single-wafer cleaning machine, in different process steps, the rotational speed of the silicon wafer changes; while in the same process, the rotational speed of the silicon wafer is constant . However, the rotational speed of the silicon wafer in a process step is critical, especially for chemical solutions with high etch rates like DHF. The inventors have found that if the silicon wafer is kept at a constant speed in one process step, it is difficult to combine the characteristics of different process steps, which is not conducive to the uniformity of DHF corrosion, and it is also difficult to prompt the old chemical solution and reaction products to leave in time. The surface of the silicon wafer leads to a sharp increase of particles on the surface of the silicon wafer.

[0032] In order to overcome the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com