Segmental thermoelectric generator structure design method

A thermoelectric generator and structural design technology, applied in the direction of generator/motor, thermoelectric device manufacturing/processing, electrical components, etc., can solve the research problems of scholars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

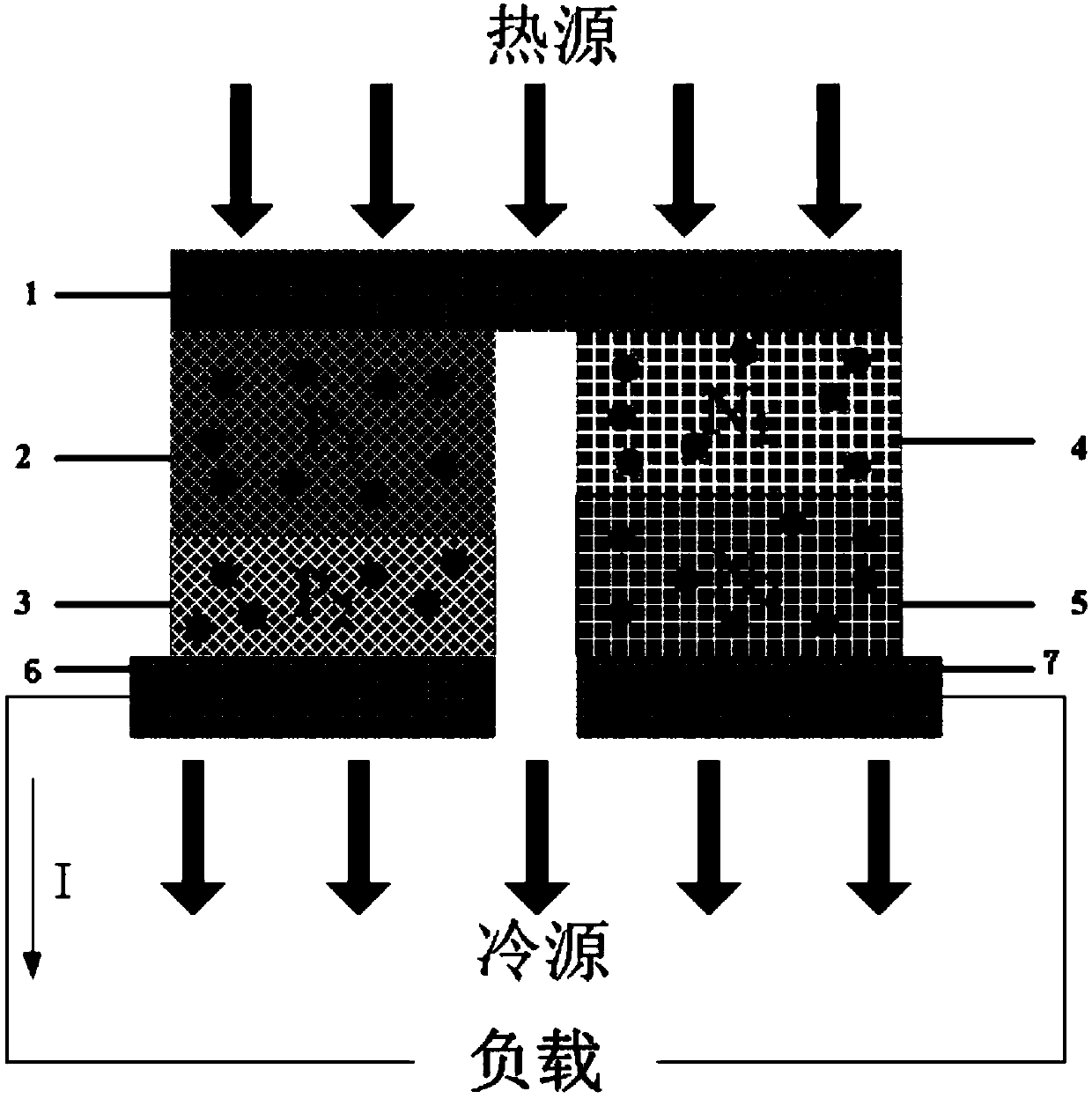

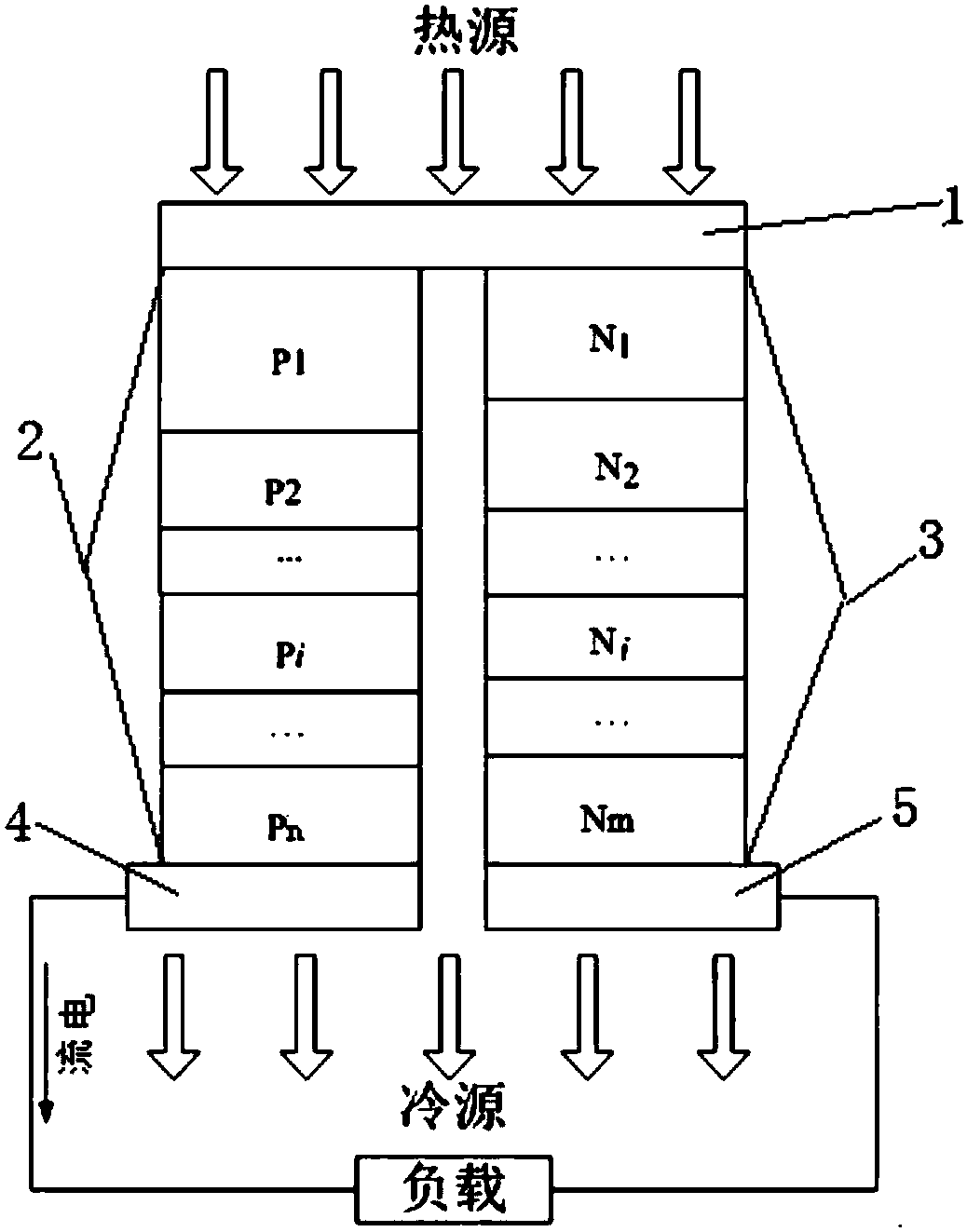

Method used

Image

Examples

Embodiment Construction

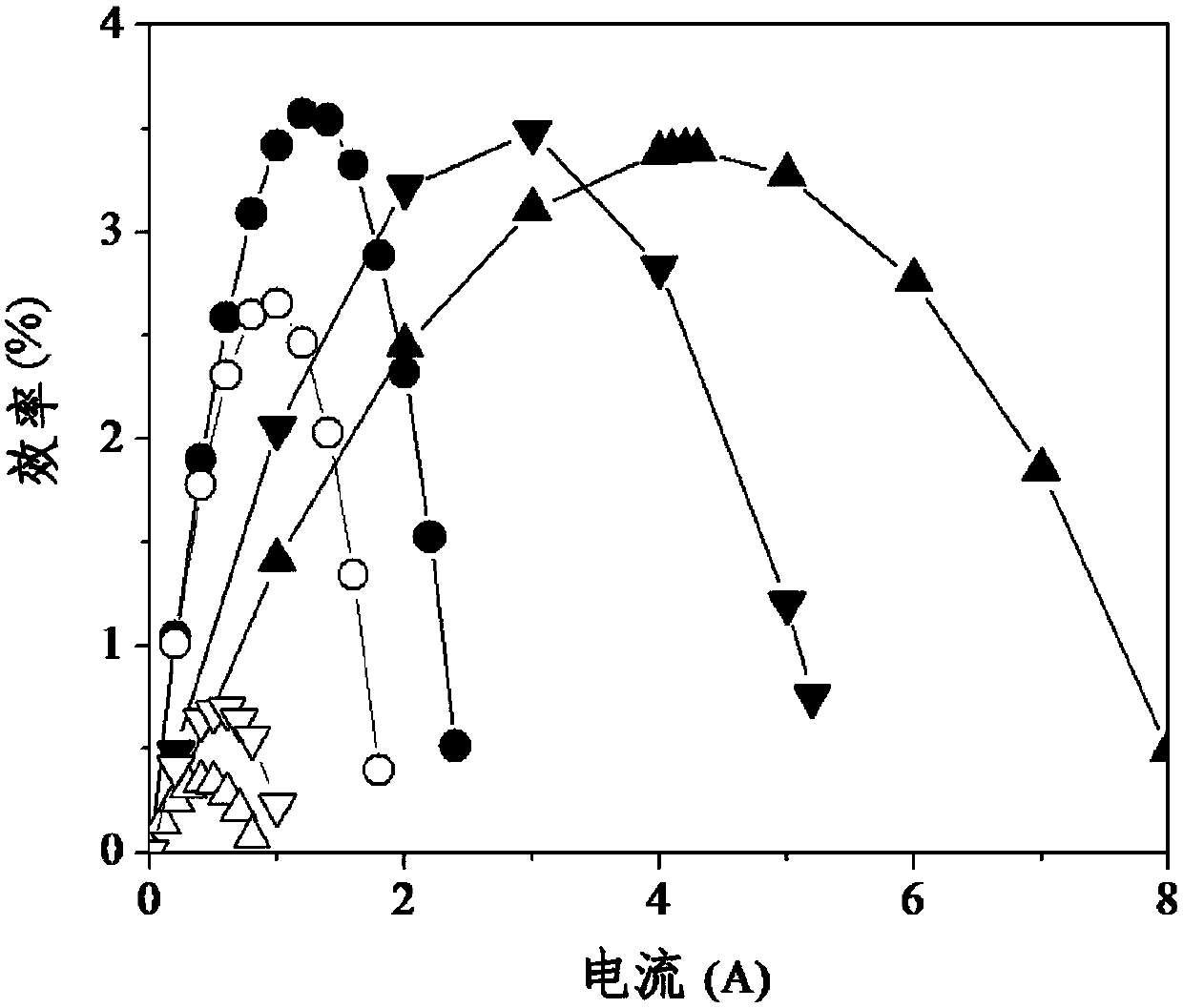

[0081] The technical scheme of the present invention will be further described below in conjunction with specific examples.

[0082] The conductive connection layer used in this example is copper, and two p-type semiconductors and two n-type semiconductors are used, and the two p-type semiconductor materials are LiNiO and BiSbTeC 60 , assuming that the physical parameters of the two n-type semiconductors are the same as those of the two p-type semiconductors, namely α n1 =-α p1 , σ n1 = σ p1 , lambda n1 =λ p1 、α n2 =-α p2 , σ n2 = σ p2 , lambda n2 =λ p2 (So all parameters of p-type semiconductor and n-type semiconductor are the same, the following design process only needs to calculate the proportion of p-type semiconductor), the physical parameters of the two p-type semiconductors are as follows:

[0083] 1. α p1 =1.76×10 -12 T 3 -4.18×10 -9 T 2 +2.57×10 -6 T-2.67×10 -4 V K -1

[0084] σ p1 =1.62×10 -6 T 5 -3.31×10 -3 T 4 +2.69T 3 -1.08×10 3 T 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com