Preparation method of poached vegetable

A vegetable and water boiling technology, applied in the direction of heating and preserving fruits/vegetables, etc., can solve the problems of poor color, crispness, flavor and taste, inability to guarantee vegetable taste, freshness and short shelf life, etc., to achieve color retention, freshness and long shelf life , to avoid the appearance of broken skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

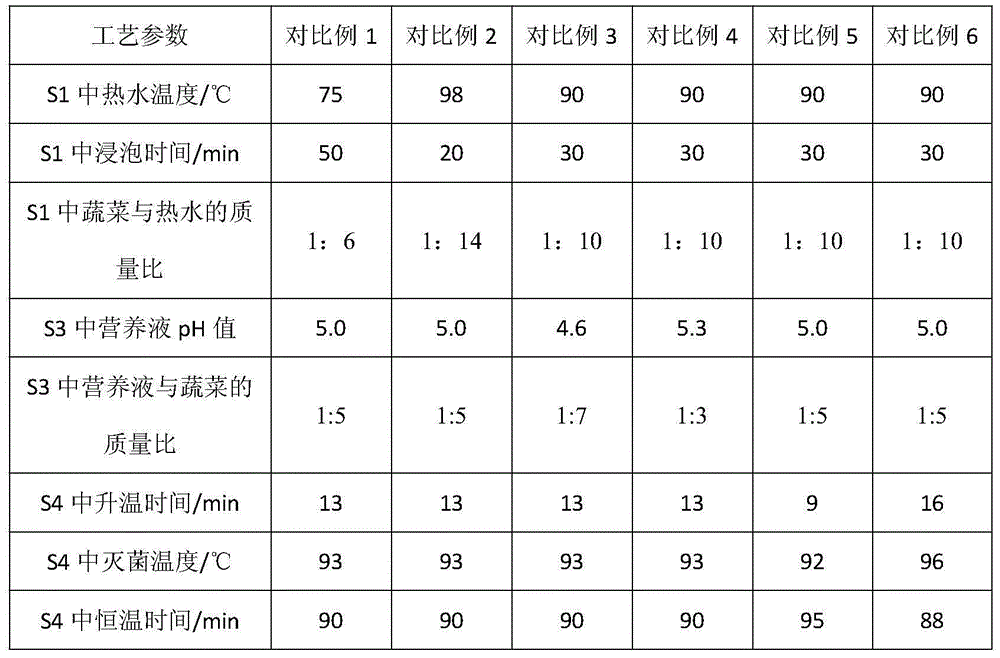

Examples

Embodiment 1

[0037] This embodiment takes the preparation of boiled bracken as an example.

[0038] A preparation method of boiled vegetables, comprising the following steps:

[0039] S1. Soak the dried bracken in 80°C hot water for 40 minutes, wherein the mass ratio of dried bracken to hot water is 1:13;

[0040] S2. Pick up the bracken treated by S1, drain it, and soak it in room temperature water for 6 hours. Then pick up the bracken, put it into room temperature water and wash it more than 3 times, each time for about 60 minutes, and turn the bracken thoroughly every 15 minutes until the washed wastewater is apparently clean.

[0041] After cleaning, the bracken is selected to remove rotten vegetables, moldy vegetables and weeds;

[0042] S3. Weigh the bracken selected in S2, pack it into bags, add the nutrient solution, and then carry out vacuum packaging. The nutrient solution consists of water, vitamin C and citric acid, and has a pH of 4.7. The mass ratio of nutrient solution t...

Embodiment 2

[0047] This embodiment takes the preparation of boiled bracken as an example.

[0048] A preparation method of boiled vegetables, comprising the following steps:

[0049] S1. Soak the dried bracken in hot water at 90°C for 30 minutes, wherein the mass ratio of dried bracken to hot water is 1:10;

[0050] S2. Pick up the bracken treated by S1, drain it, and soak it in room temperature water for 5 hours. Then pick up the bracken, put it into room temperature water and wash it more than 3 times, each time for about 60 minutes, and turn the bracken thoroughly every 20 minutes until the washed wastewater is apparently clean.

[0051] After cleaning, the bracken is selected to remove rotten vegetables, moldy vegetables and weeds;

[0052] S3. Weigh the bracken selected in S2, pack it into bags, add the nutrient solution, and then carry out vacuum packaging. The nutrient solution consists of water, vitamin C and citric acid, and has a pH of 5.0. The mass ratio of nutrient solutio...

Embodiment 3

[0057] This embodiment takes the preparation of boiled bracken as an example.

[0058] A preparation method of boiled vegetables, comprising the following steps:

[0059] S1. Soak the dried bracken in hot water at 95°C for 25 minutes, wherein the mass ratio of dried bracken to hot water is 1:7;

[0060] S2. Pick up the bracken treated by S1, drain it, and soak it in room temperature water for 4 hours. Then pick up the bracken, put it into room temperature water and wash it more than 3 times, each time for about 60 minutes, and turn the bracken thoroughly every 25 minutes until the washed wastewater is apparently clean.

[0061] After cleaning, the bracken is selected to remove rotten vegetables, moldy vegetables and weeds;

[0062] S3. Weigh the bracken selected in S2, pack it into bags, add the nutrient solution, and then carry out vacuum packaging. The nutrient solution consists of water, vitamin C and citric acid, and has a pH of 5.2. The mass ratio of nutrient solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com