Fully-digital intelligent restaurant system and catering method

A fully digital and intelligent technology, applied in the field of kitchen utensils, can solve the problems of ineffective control of food hygiene and safety, high labor costs, and low catering efficiency, so as to eliminate food safety risks, reduce labor costs, and save terminal manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

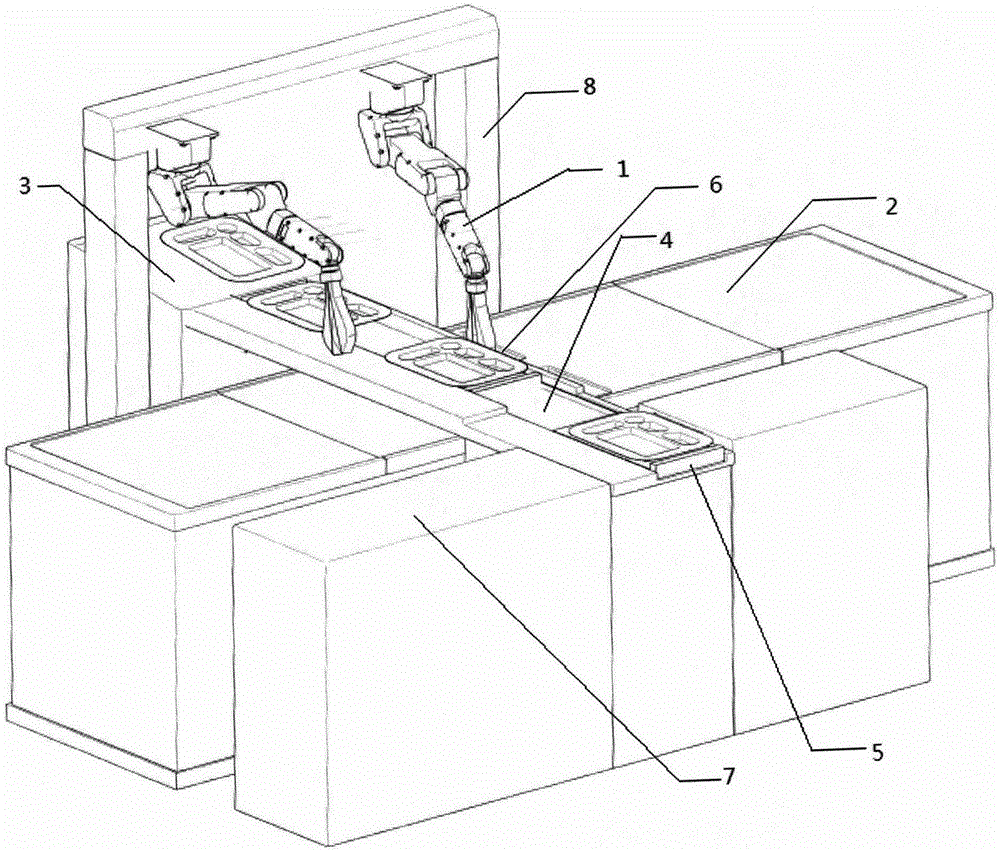

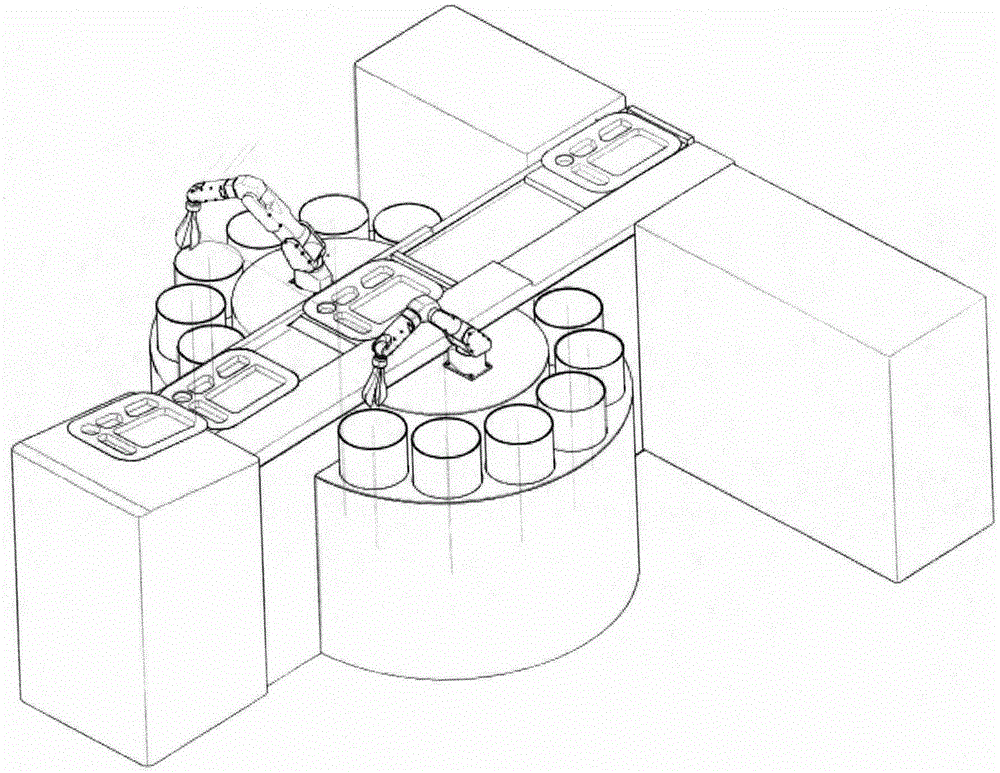

[0022] It can be seen from the accompanying drawings that it is an all-digital intelligent restaurant system. It includes: a servo dish supply system 2, an automatic serving system 3, an automatic transmission system 4, a catering robot 1, a frame 8, a meal taking channel 7, and a lateral push rod. It is characterized in that the catering robot 1 is installed On the frame 8, the automatic transmission system 4 is below the frame 8 and passes through the frame 8. The servo dish supply system 2 is arranged under the catering robot 1, and the meal-taking channel 7 is arranged on the automatic transmission system. At the end of 4, the lateral push rod is arranged at the end of automatic transmission system 4. It can realize the core requirements of full unattended operation, high efficiency of 5-8 servings / min, safe and hygienic environment, pre-customization and remote operation.

Embodiment 2

[0024] As an improvement of the present invention, the automatic plate offering system 3 is composed of a stepping motor, a screw, a plate platform, a limit rod, a horizontal push rod, a pressure trigger sensor and a PLC controller. After adopting this design, firstly the stepping motor is started, and the screw pushes the platform to move upwards. When the uppermost plate touches the pressure trigger sensor, the sensor feeds back a signal to the controller, and the stepping motor stops, and then the horizontal push rod moves to push out the most For the upper dinner plate, after the horizontal push rod is reset, the trigger sensor is opened again, and the stepping motor moves again to push the platform upwards, so that the new uppermost dinner plate contacts the pressure trigger sensor. Repeat the action to complete the process of automatic offer. The rest of the structural features and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0026] As an improvement of the present invention, the servo dish supply system 2 is composed of a servo motor controller, a PLC controller, a customized circuit board, a horizontal slide rail, a trailer, a vegetable storage bucket and a catering robot. After adopting this design, firstly, the host control system sends out the command of the selected dish, and the command is transmitted to the PLC controller of the intelligent servo food supply system. The trailer moves to the corresponding position, so that the corresponding vegetable bucket on the trailer is just located under the catering robot, and it is convenient to pick up the corresponding dishes. Then according to the instructions of different dishes, quickly adjust the corresponding position to achieve fast switching of dishes. All the other structures and advantages are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com