Energy-saving and environment-friendly glove box workstation and method for regeneration of glove box purification unit

A purification unit, energy saving and environmental protection technology, applied in chemical instruments and methods, separation methods, manipulators, etc., can solve the problems of increased purchase cost and maintenance cost, and achieve the goals of avoiding repeated waste, quick disassembly and assembly, and reducing use and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

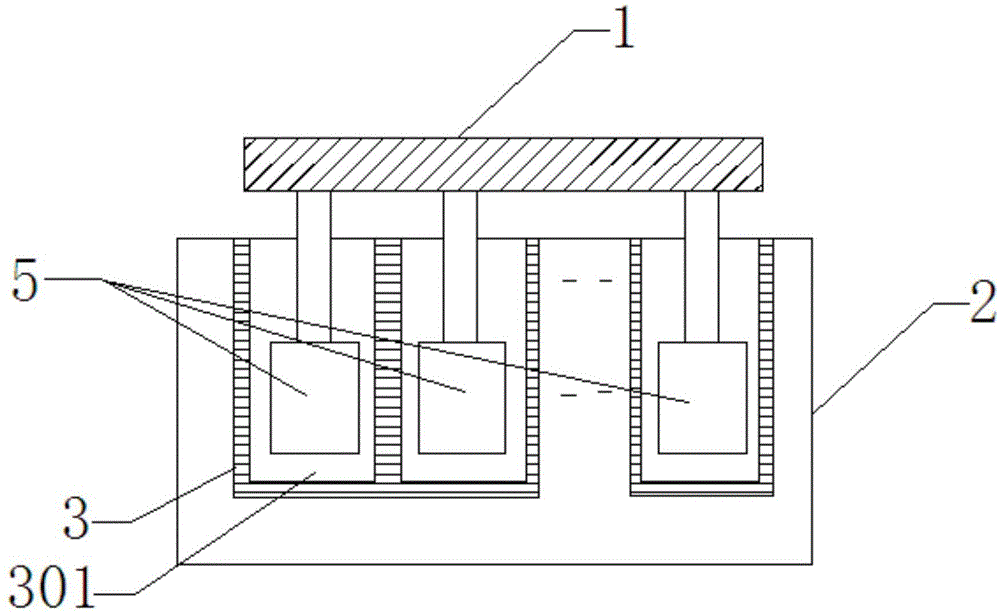

Embodiment 1

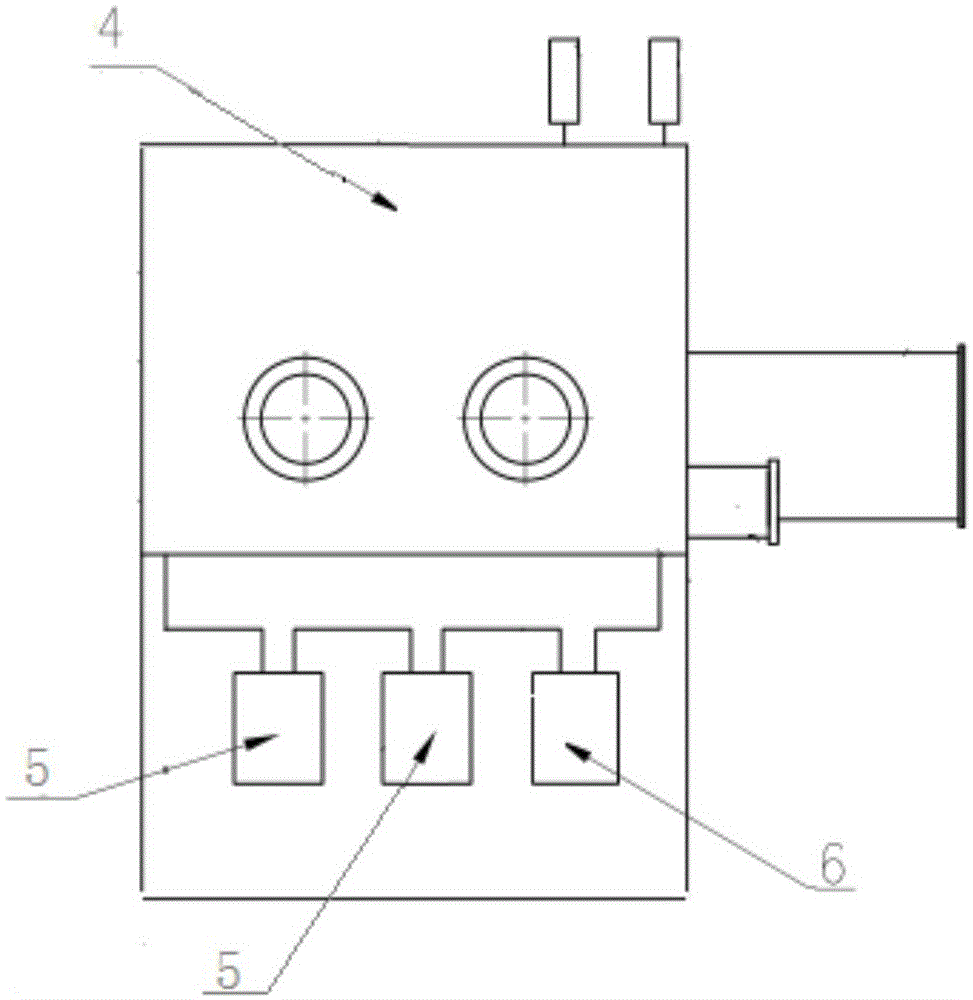

[0046] 1) Place the purification unit of the used glove box in the purification unit placement area;

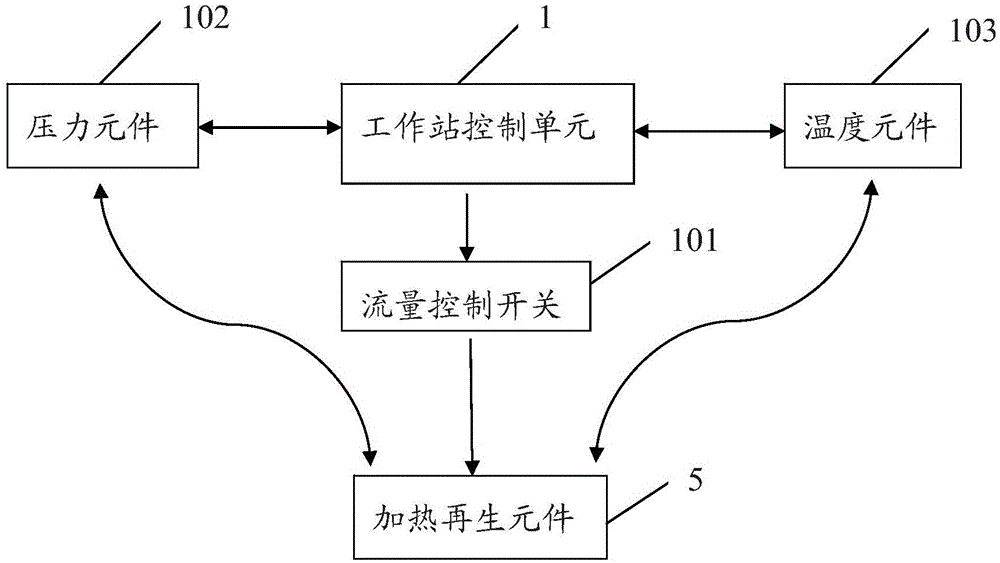

[0047] 2) After the workstation control unit senses the purification unit, the heating regeneration element is started, and under the control of the control unit, the heating regeneration element is heated and pressurized, and the airflow entering the heating regeneration element is controlled , so that the purification unit is regenerated; the purification unit is regenerated under the method comprising the following steps, the heating and regeneration element is evacuated to 100 Pa, maintained for 30 minutes, and then heated to 250 ° C within 5 minutes and maintained for 1 hour, and then pressed Add 5% hydrogen-nitrogen mixed gas at 400ml / min for 40min, repeat the above process 5 times, then stop heating and vacuumize for 5 hours, and then fill it up to normal pressure.

Embodiment 2

[0049] The specific regeneration method is the same as that in Example 1, except that the purification unit is regenerated under the method comprising the following steps: vacuumize the heating regeneration element to 1000 Pa, maintain it for 60 minutes, and then heat it to 200°C within 10 minutes and maintain it 2h, then press 250ml / min to supplement 5% hydrogen-nitrogen mixed gas for 60min, cycle the above process 5 times, then stop heating and vacuumize for 5 hours, and supply the gas to normal pressure.

Embodiment 3

[0051] The specific regeneration method is the same as that in Example 1, except that the purification unit is regenerated under the method comprising the following steps: evacuate the heating regeneration element to 100 Pa, maintain it for 30 minutes, and then heat it to 250° C. within 5 minutes and maintain it 1h, then press 350ml / min to supplement 5% hydrogen-nitrogen mixed gas for 45min, cycle the above process 5 times, then stop heating and vacuumize for 5 hours, and supply the gas to normal pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com