Multi-beam laser interference cross-scale 3D (three dimension) printing system and method

A technology of laser interference and 3D printing, applied in the direction of additive processing, etc., can solve the problems of inability to realize 3D printing of micro-nano composite structure materials, and achieve the effect of good pattern density adjustment, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

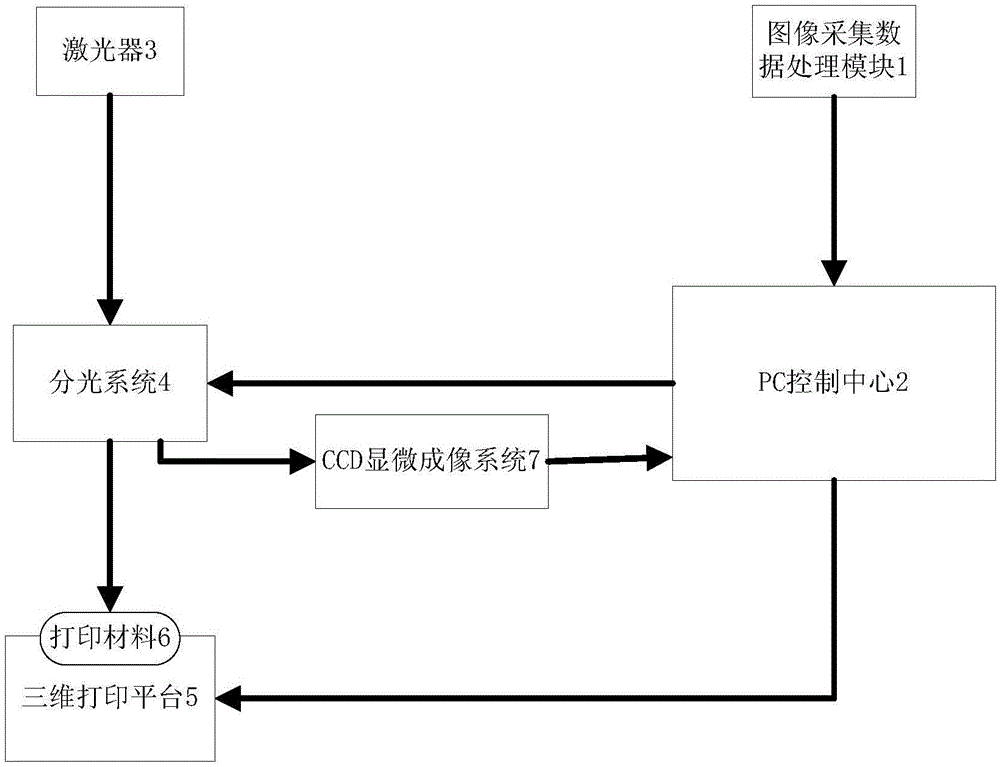

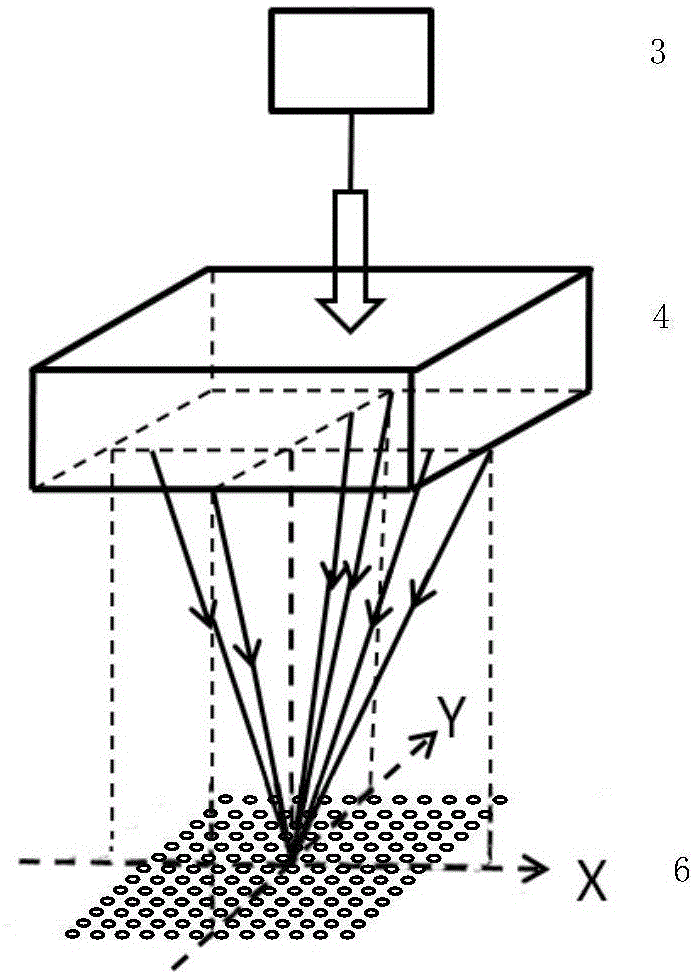

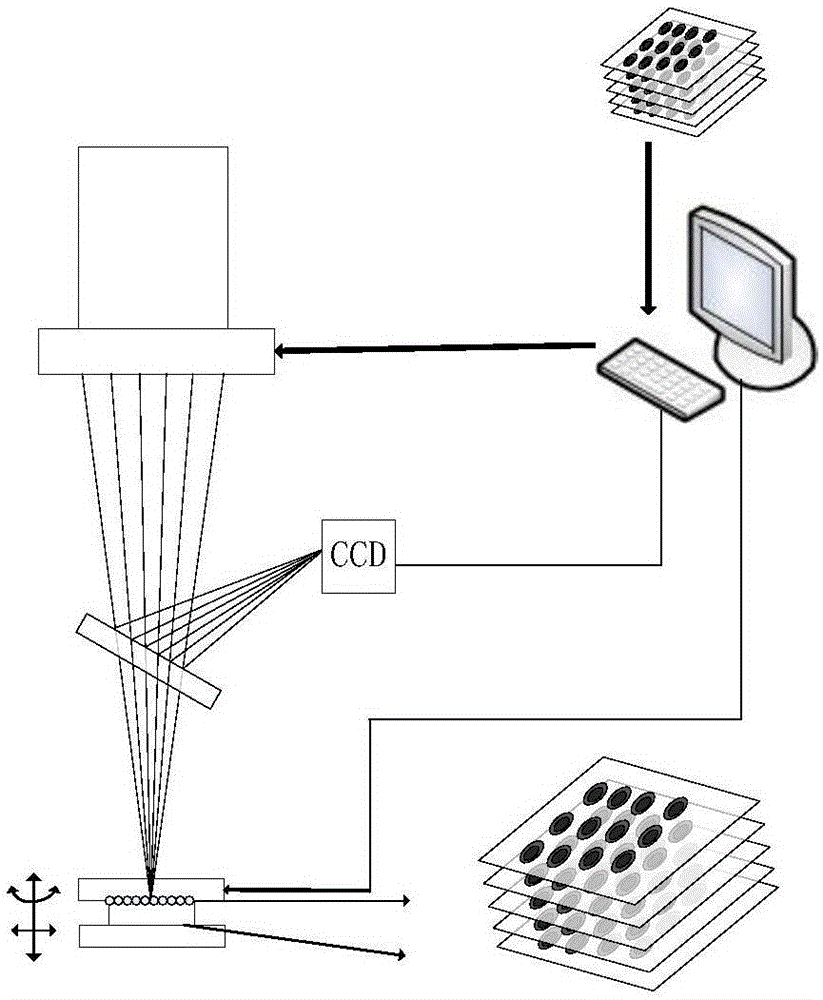

[0038] Such as figure 1 As shown, a multi-beam laser interference cross-scale 3D printing system of the present invention includes: an image acquisition data processing module 1, a PC control center 2, a laser 3, a spectroscopic system 4, a three-dimensional printing platform 5, printing materials 6, and CCD microscopic imaging System 7. Firstly, the image acquisition data processing module 1 generates layers of physical models after 3D scanning of the printed objects, and transmits them to the PC control center 2; according to the size requirements of the printed nano-patterns, the PC control center 2 simulates the physical model of the 3D nano-pattern structure and sets up the spectroscopic system 4 parameters, so that the beam splitting system 4 divides the single laser beam output by the laser 3 into multiple beams of coherent light, and sets the incident angle and spatial angle of each coherent beam, and the polarization states of each coherent light are consistent. Mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com