Method and system for simulating moth compound eye optical antireflection structure pattern

A structural pattern and anti-reflection technology, which is applied in microlithography exposure equipment, photolithography exposure equipment, electrical components, etc., can solve the problems of increased reflection loss, expensive PECVD deposition, adhesion effect, thermal matching film stability, etc. problems, to achieve the effect of high efficiency, low cost, and large exposure field area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

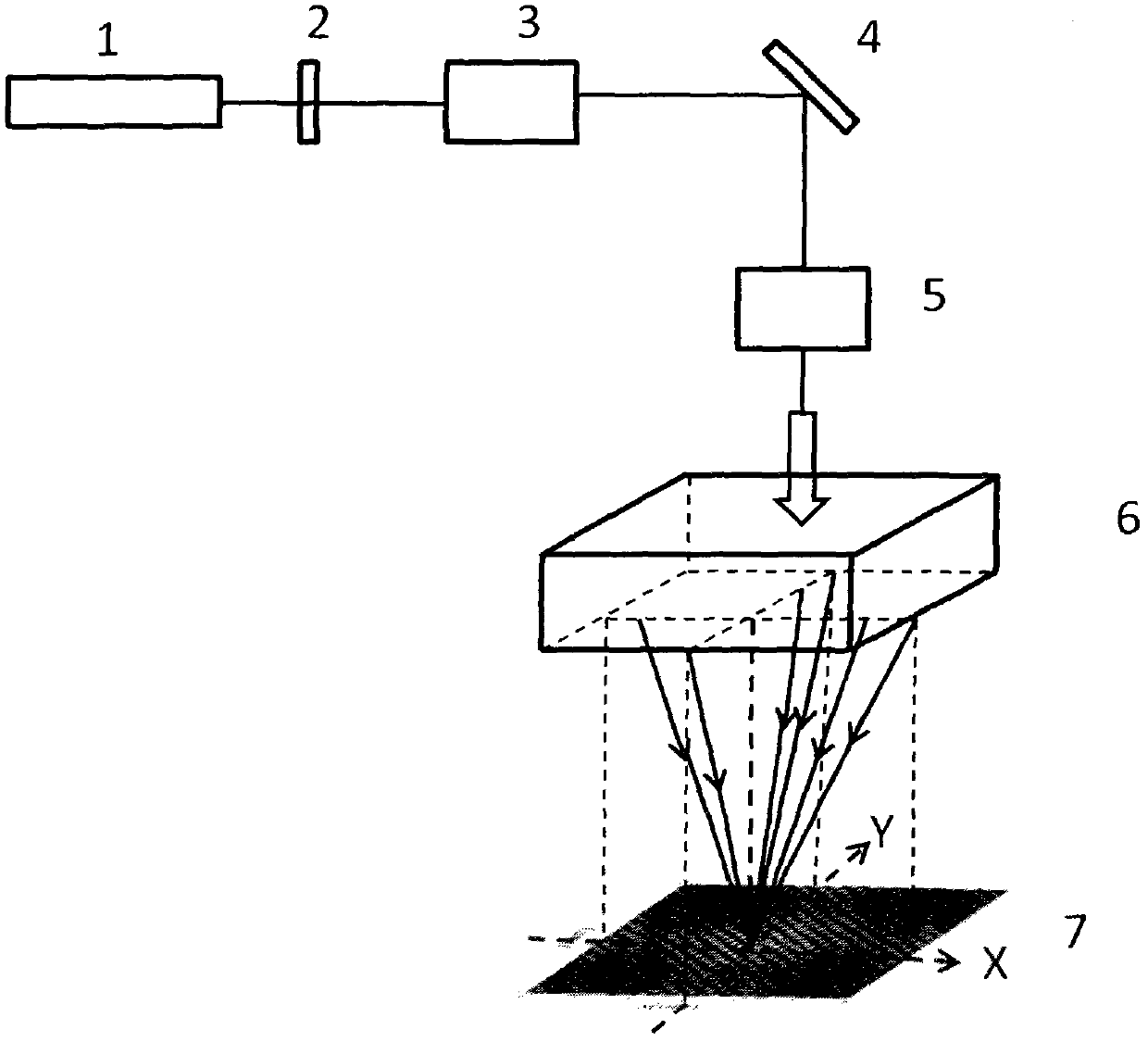

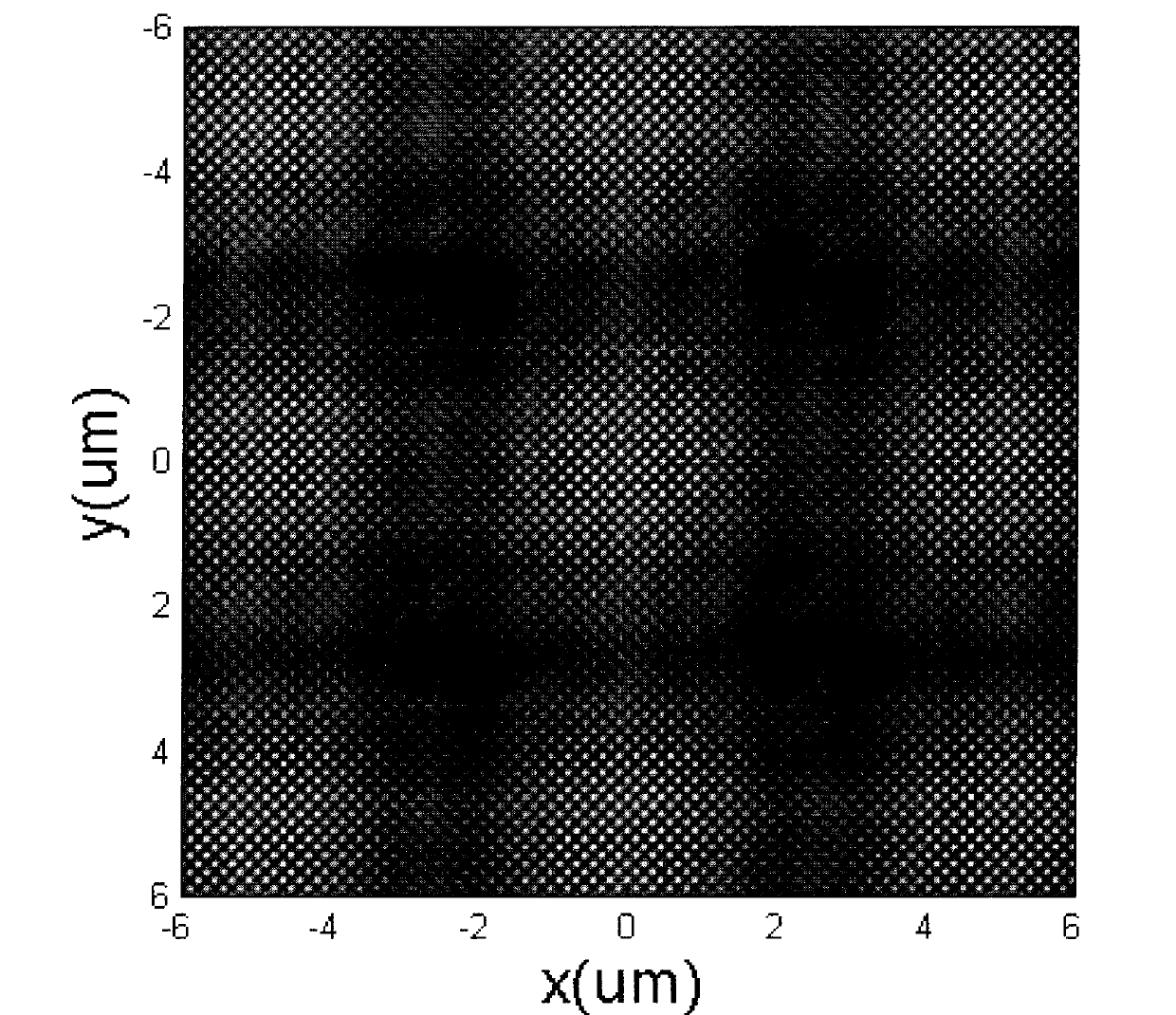

[0029] Such as figure 1 As shown, it is a schematic diagram of the system for realizing the moth compound eye optical anti-reflection structure pattern by six-beam interference in the present invention. The laser interference system used includes a laser 1, a beam expander 2, a collimation system 3, a mirror 4, and a polarizing device 5 , beam splitting and refraction system 6, CCD 7. After the laser beam emitted by the laser 1 is expanded 2 and collimated 3, the optical path is refracted by the reflector 4, and the beam is converted into linearly polarized light by the polarizing device 5, and then the laser beam is divided into Six coherent light beams, and then each three beams of the six beams of light are respectively incident on the X and Y planes, so that they are simultaneously irradiated on the CCD 7 at a certain incident angle, forming a periodic optical anti-reflection structure pattern of the compound eye of the moth.

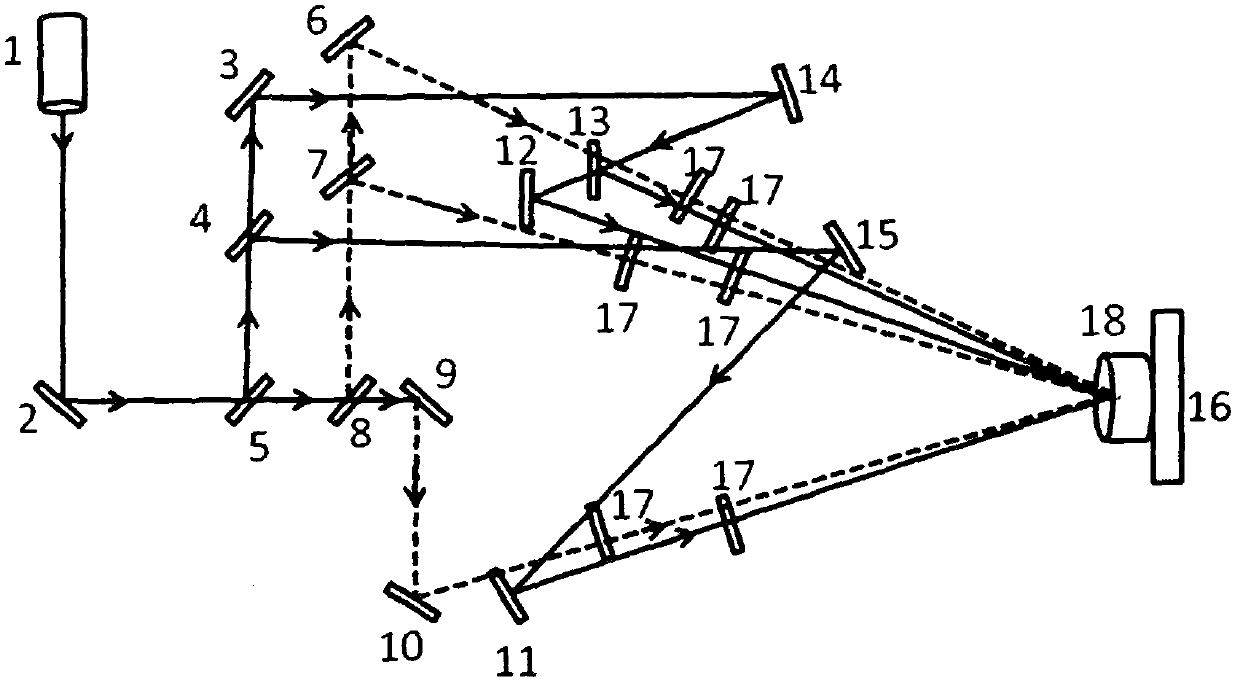

[0030] use figure 2 The shown six-beam int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com