Method for preparing low-friction and high-hardness artificial hip joint ball head by surface patterning

A hip, low-friction technology, used in hip joints, joint implants, joint implants, etc., can solve the problems affecting the anti-wear ability of artificial joints and the internal stress of materials, reducing the real contact area, Shape and quality more, precise and controllable effects of shape and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

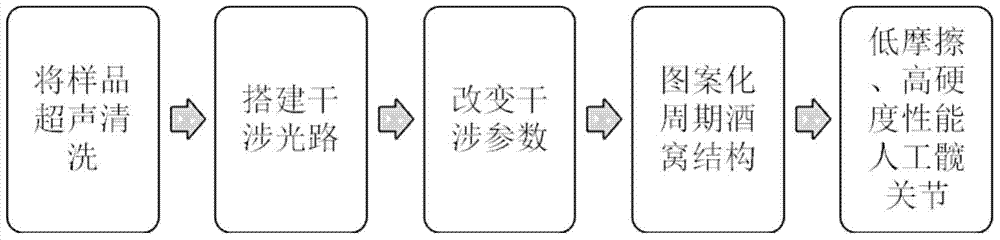

[0031] figure 1 As shown, the present invention is realized as:

[0032] Forming a patterned dimple array on the surface of the artificial hip joint ball, that is, preparing a patterned dimple array on the friction surface of the artificial hip joint ball by laser interference lithography, including the following steps:

[0033] a. Ultrasonic cleaning of the hip joint;

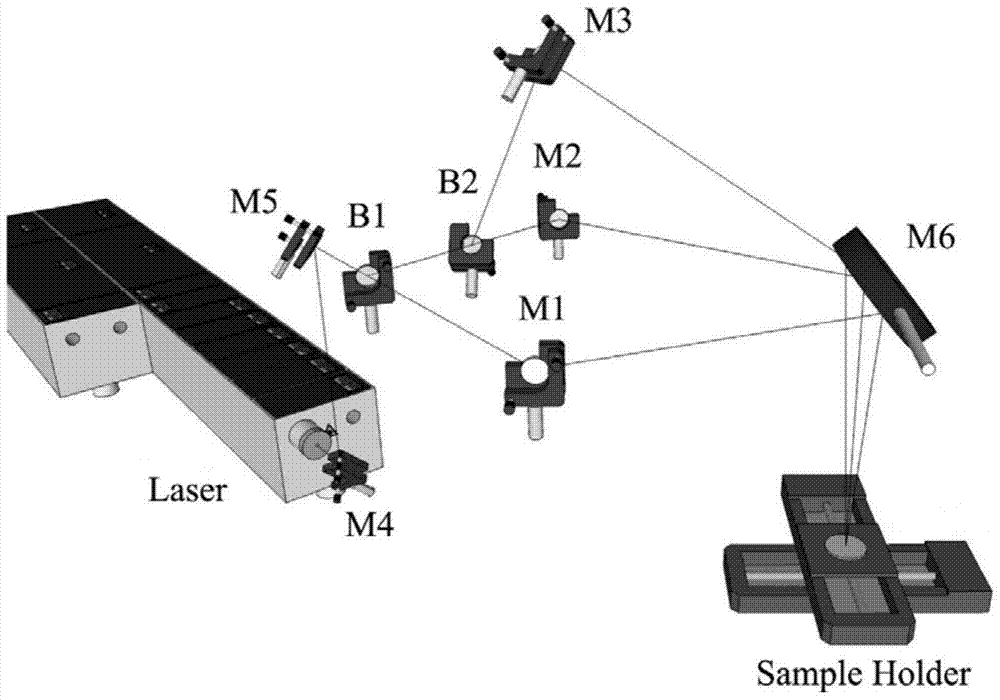

[0034] b. Establish a three-beam laser interference optical system to etch samples;

[0035] c. Change the three-beam interference parameters to obtain a periodic lattice structure with adjustable structural period from nanometer to micrometer and controllable depth;

[0036] d. Optimize the interference light intensity and exposure time parameters of the three-beam interference system to obtain a low-friction, high-hardness artificial hip joint ball head.

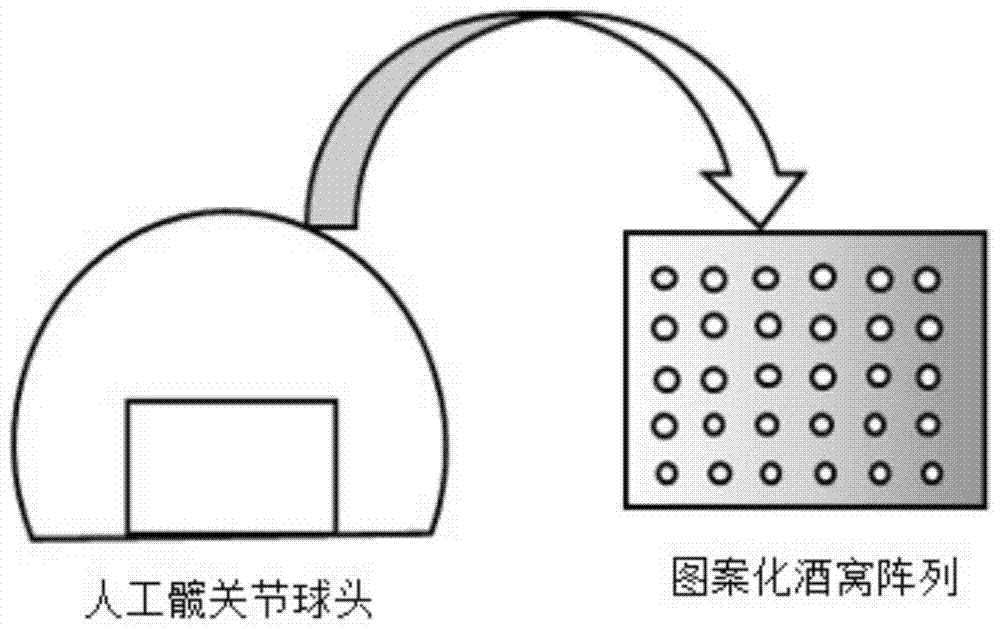

[0037] Such as figure 2 As shown, it is a model diagram of the artificial hip joint ball head prepared by the present invention; the artificial hip j...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com