Method for preparing nanometer hole graphene in heat contact mode

A technology of nano-holes and graphene, which is applied in the field of preparation of nano-holes graphene, can solve problems such as difficult collection, powder flying, and insufficient safety, so as to avoid danger and inconvenient collection, avoid powder flying, large-scale and fast The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

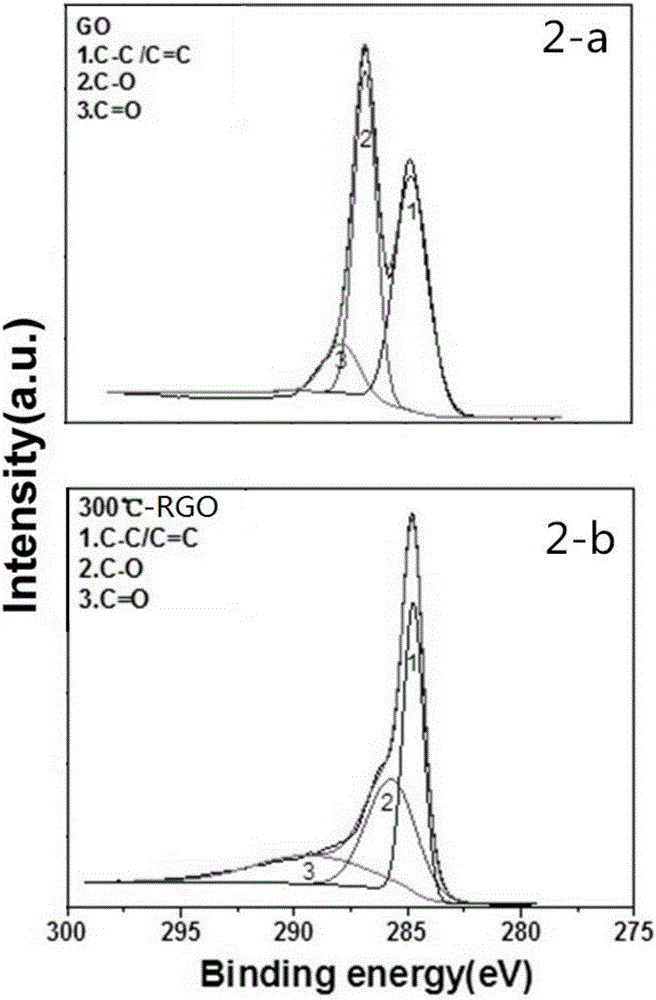

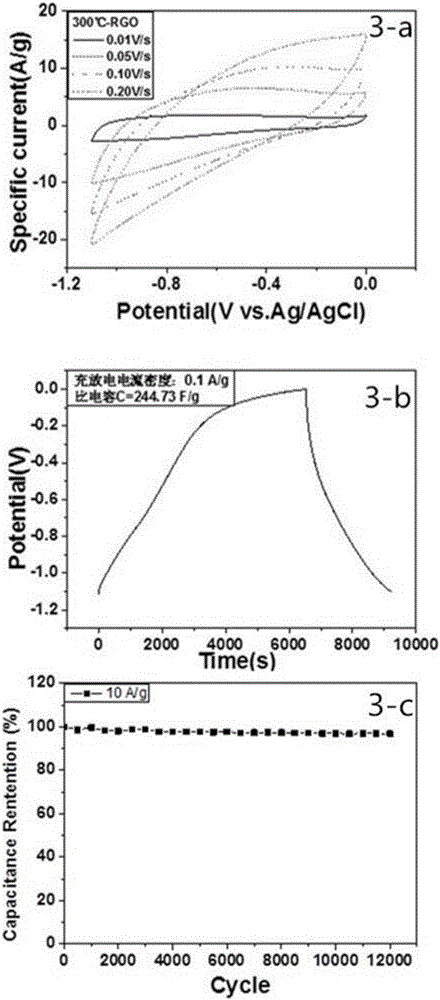

[0035] In this embodiment, graphene oxide airgel is used as a raw material to prepare large specific surface area and nanoporous graphene airgel, which is carried out according to the following steps:

[0036] Step a, prepare graphene oxide by improved Hummers method, and disperse it into a suspension with deionized water, the concentration is 10mg / mL.

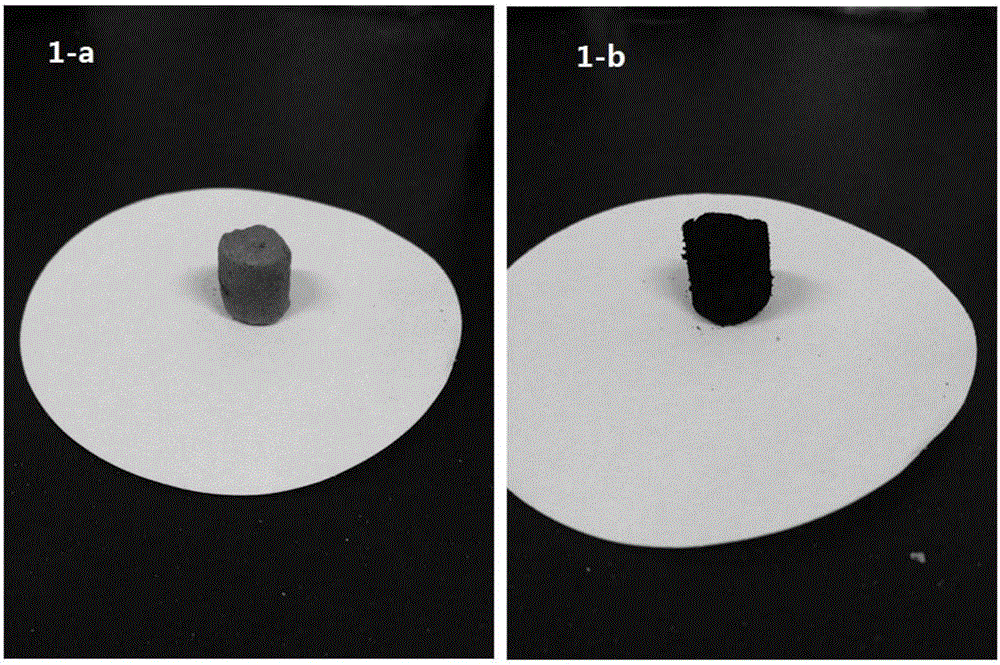

[0037] Step b, freeze-drying the graphene oxide suspension in step a: first put the graphene oxide suspension in a refrigerator to freeze into a solid, and then put it into a freeze dryer whose cold well temperature has reached -50°C to dry, that is Graphene oxide airgel can be obtained as figure 1 The brown columnar airgel solid shown in -a.

[0038]Step c, under the air atmosphere, preheat the heating platform, and adjust the temperature to 300° C., and after the temperature stabilizes, place the graphene oxide airgel in step b directly on the heating platform. After waiting for about 0.1 second, the graphene oxide airgel ...

Embodiment 2

[0045] Step a, prepare graphene oxide by improved Hummers method, and disperse it into a suspension with deionized water, the concentration is 10 mg / mL.

[0046] Step b. Apply the graphene oxide suspension in step a evenly on a flat glass sheet, place it in a constant temperature drying oven at a temperature of 55°C, let the water evaporate, and then tear off the dried film to obtain a smooth surface. And interlayer dense graphene oxide paper.

[0047] Step c, under the air atmosphere, preheat the heating table, and adjust the temperature to 250° C., and after the temperature stabilizes, place the graphene oxide paper in step b directly on the heating table. Wait for about 2-3 seconds, and you can get reduced graphene oxide, that is, nanoporous graphene paper. like Figure 7 As shown in , 7-a is tan smooth surface graphene oxide paper (GO), 7-b is black expanded rough surface nanoporous graphene paper (RGO). 7-c and 7-d are optical photographs of the cross-sections of graph...

Embodiment 3

[0050] Step a, prepare graphene oxide by improved Hummers method, and disperse it into a suspension with deionized water, the concentration is 10mg / mL.

[0051] Step b, freeze-drying the graphene oxide suspension in step a: first put the graphene oxide suspension in a refrigerator to freeze into a solid, and then put it into a freeze dryer whose cold well temperature has reached -50°C to dry, that is Graphene oxide airgel can be obtained as Figure 9 The brown columnar airgel solid shown in -a.

[0052] Step c, under the air atmosphere, preheat the heating platform, and adjust the temperature to 200°C. After the temperature is stable, place the graphene oxide airgel in step b directly on the heating platform. Wait for about 3-5 seconds, the graphene oxide airgel starts to burn from the contact point of the heating platform, accompanied by expansion, until the whole airgel is completely burned, and the burning time is about 0.01s. can be obtained as Figure 9 The black nanop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com