Circulating fluidized bed coal gas purification method

A circulating fluidized bed and gas technology, which is applied in combustible gas purification, combustible gas purification/transformation, and combustible gas manufacturing. It can solve the problems of high consumption, reduce washing water volume, wide adjustable range, and increase flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

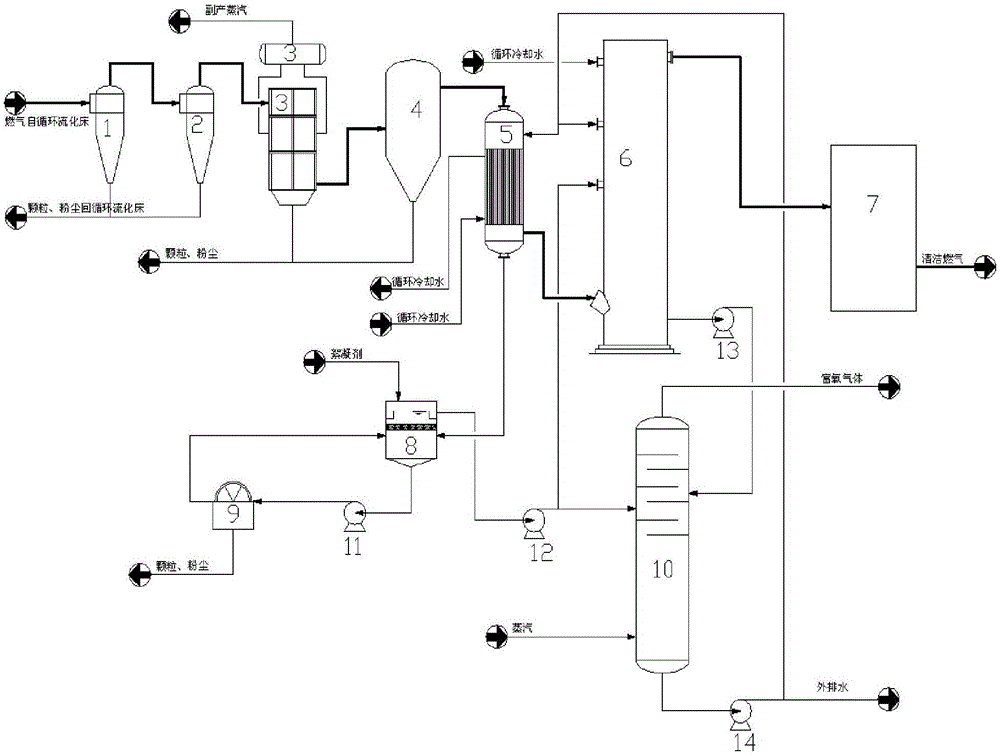

[0028] An embodiment of the present invention see figure 1 , the high-temperature gas from the circulating fluidized bed passes through the two-stage cyclone separator (1, 2) for dust removal and separation, and then enters the waste heat boiler (3) for waste heat recovery, and the gas after waste heat recovery passes through the dry dust collector (4) in turn , gas cooler (5), scrubber (6), enters the desulfurization system (7), and the gas that exits the desulfurization system is sent to the user. The gas is cooled in the gas cooler (5) by a combination of direct spraying and indirect heat exchange, the gas condensed water enters the clarification tank (8), and the bottom liquid of the clarification tank with high dust content is pumped with a clarification tank bottom pump (11 ) into the filtration system (9) for filtration, the filtrate returns to the clarifier, and the clear liquid from the clarifier is sent to the stripper (10) for deamination. The gas condensed water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com