Pit slot cleaning equipment and optimal parameter determination method

A technology for cleaning equipment and potholes, which is applied to roads, road repairs, roads, etc., can solve the problems of reduced bond strength, increased internal stress, and debris residue on the bonding surface, making it easy to carry and use, and improve bonding Effect, the effect of improving the repair life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

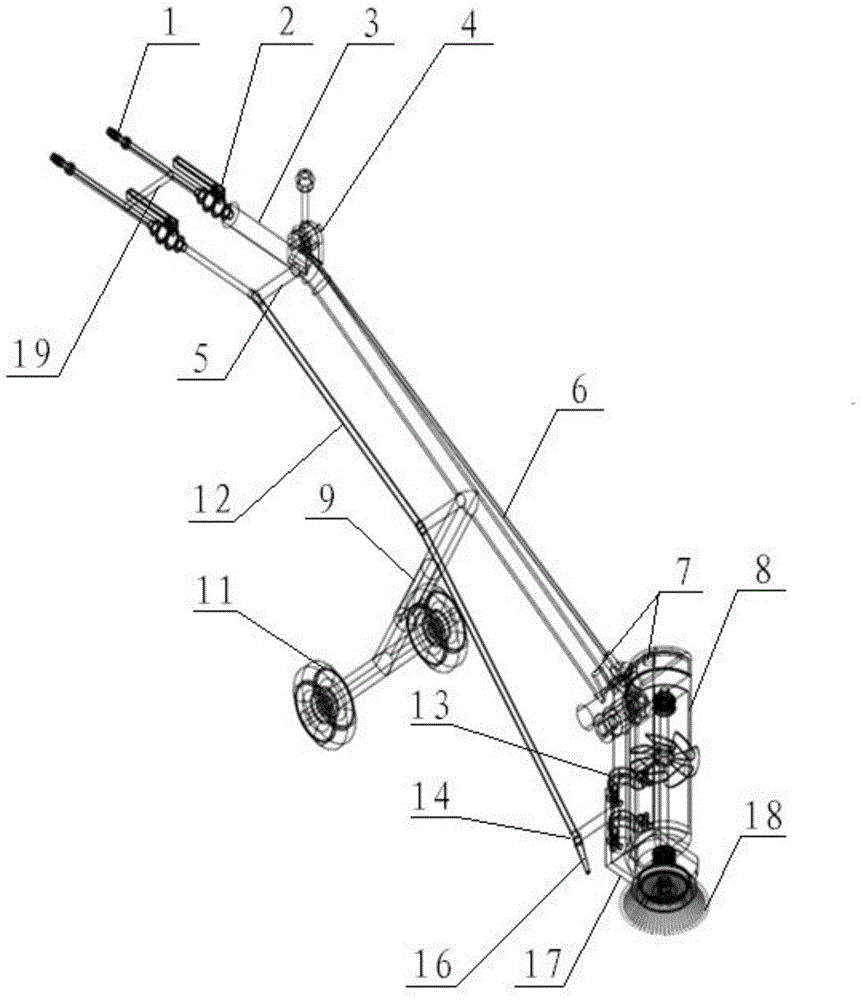

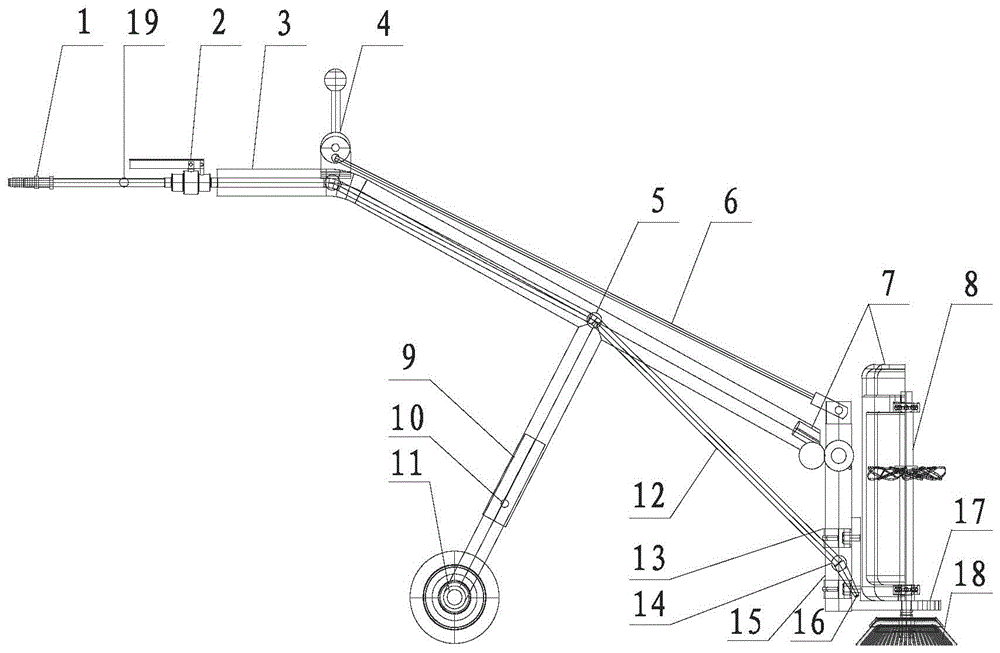

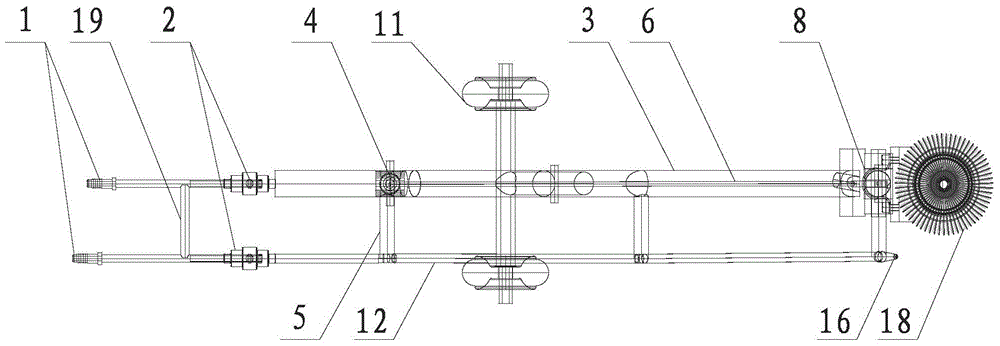

[0048] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0049] 1. Equipment part

[0050] see Figure 1 to Figure 8 , the pothole cleaning equipment of the present invention mainly uses the rotating steel wire brush head quota and the high-pressure air spray gun to clean the dust and gravel on the pothole repair interface and remove the loose surface on the repair interface, and at the same time remove the water stains on the repair interface , to achieve the purpose of providing a clean, dry pit repair interface with good contact conditions. This equipment has an air motor 8 driven by high-pressure air to rotate. The air pipe and the air motor 8 are connected together through the air pipe interface 7 respectively arranged on the two, and the air motor 8 drives the cleaning brush head 18 to clean the pits. The purpose of patching the interface. Each part of the equipment is a modular independent part, which can be repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com